Urea sulfate coated urea slow-release granular fertilizer and preparation method therefor

A technology of slow-release granular fertilizer and coated urea, applied in urea compound fertilizer, nitrogen fertilizer, fertilization device, etc., can solve the problems of thick sulfur coating film, expensive resin film, coating cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

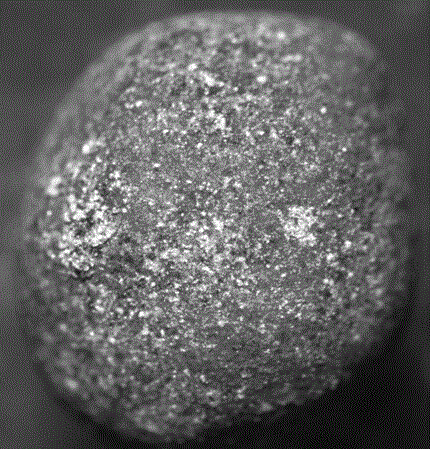

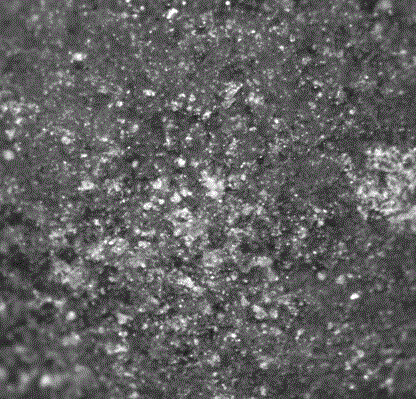

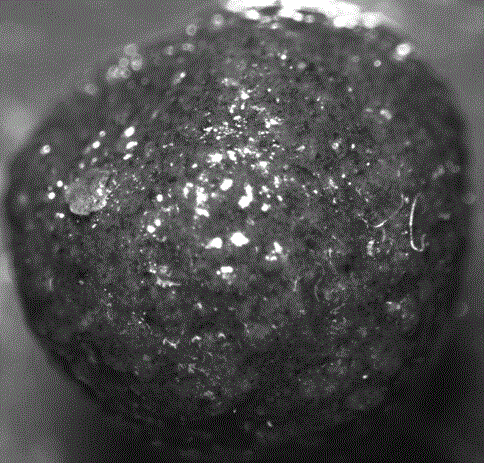

[0026] Example 1 Urea Sulfate Coated Urea Slow Release Granular Fertilizer

[0027] Urea sulfate-coated urea slow-release granular fertilizer, from inside to outside, respectively, urea particles with a diameter of 2-4.5mm, urea sulfate silicate slow-release film, and sealing film;

[0028] The described urea sulfate silicate slow-release film is a film made of urea sulfate as binder and silicate powder as aggregate;

[0029] The silicate powder is silicate clinker with a particle size of 200-300 mesh;

[0030] The sealing film is paraffin, and the paraffin is a mixture of liquid wax and solid wax, and their percentages by weight are 20-70% and 80-30% respectively.

Embodiment 2

[0031] Embodiment two The preparation of bonding sustained-release agent urea sulfate

[0032] 1. Slowly add 1kg of 98wt% concentrated sulfuric acid to 10kg of urea, and react in the reaction tank to obtain a viscous urea sulfate solution for later use.

[0033] 2. Slowly add 1kg of 90wt% concentrated sulfuric acid to 1kg of urea, and react in the reaction tank to obtain a viscous urea sulfate solution for later use.

[0034] 3. Slowly add 2kg of 98wt% concentrated sulfuric acid to 1kg of urea, and react in a reaction tank to obtain a viscous urea sulfuric acid solution for later use.

[0035] 4. Slowly add 1kg of 95wt% concentrated sulfuric acid to 5kg of urea, and react in a reaction tank to obtain a viscous urea sulfate solution for later use.

Embodiment 3

[0036] Example 3 Preparation of mounting medium

[0037] The liquid wax and solid wax are heated to 50-60°C and mixed, and their weight percentages are 20-70% and 80-30% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com