High-activity straw organic-inorganic fertilizer and preparation method thereof

An inorganic fertilizer and high-activity technology, applied in organic fertilizers, inorganic fertilizers, alkaline orthophosphate fertilizers, etc., can solve problems such as solution intractability, improve and activate soil, improve crop quality and yield, and increase reproductive activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

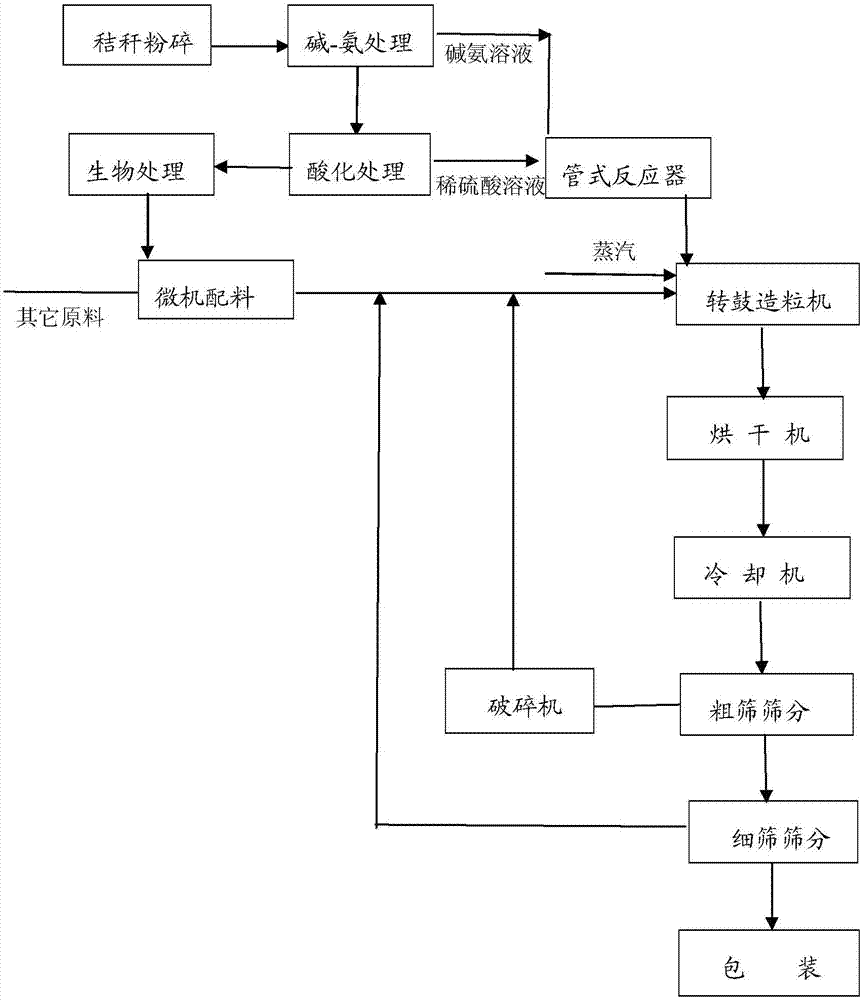

[0030] Such as figure 1 Shown, a kind of highly active straw organic-inorganic fertilizer preparation method of the present invention comprises the following steps:

[0031] (1) Pretreatment of straw (standby)

[0032] A. Crush: Crush the straw to 40-50 mesh.

[0033] B. Alkali-ammonia compound treatment: make 20% alkali-ammonia solution from urea and calcium hydroxide each accounting for 4-6% of the mass percentage of straw, heat it to 70-80°C, mix it evenly, and spray wine after step A Put it on the treated straw, seal it, store it for 3-4 days, take it out and dry it, and collect the remaining alkaline ammonia solution for later use.

[0034] C. Acidification treatment: make 20% dilute sulfuric acid solution with concentrated sulfuric acid (concentration ≥ 93%) accounting for 4-6% of the straw mass percentage, spray wine evenly on the straw treated by step B, and store for 1-2 days Take it out and dry it, and collect the remaining dilute sulfuric acid solution for later ...

Embodiment 1

[0054] Prepare a product with 16% organic matter content and 30% nitrogen, phosphorus, and potassium nutrient content, taking the raw material consumption quota for 1 ton of product as an example:

[0055] Specific production process:

[0056] 1. Straw pretreatment:

[0057] (1) Crush 1 ton of wheat and rice straw to 50 mesh.

[0058] (2) Make 20% alkaline ammonia solution with 50 kg of urea and 50 kg of calcium hydroxide, heat it to 75°C, mix it evenly, spray wine on the crushed straw, seal it, store it for 3 days, take it out and dry it. The alkaline ammonia solution is collected into the storage tank.

[0059] (3) Make 50 kg of concentrated sulfuric acid (concentration 95%) into a dilute sulfuric acid solution with a concentration of 20%, spray wine evenly on the straw treated in the previous step, store it for 2 days, take it out and dry it, and collect the remaining dilute sulfuric acid solution into a storage tank middle.

[0060] (4) Dissolve 3.5 kg of crude fiber q...

Embodiment 2

[0066] Prepare a product with 18% organic matter content and 32% nitrogen, phosphorus, and potassium nutrient content, taking the raw material consumption quota for 1 ton of product as an example:

[0067] Specific production process:

[0068] 1. Straw pretreatment:

[0069] (1) Crush 1 ton of corn and rice straw to 50 mesh.

[0070] (2) 55 kg of urea and 55 kg of calcium hydroxide are made into 20% alkali ammonia solution, heated to 80°C, mixed evenly, sprayed wine on the crushed straw, sealed, stored for 2 days, taken out to dry, and the remaining The alkaline ammonia solution is collected into the storage tank.

[0071] (3) Make 55 kg of concentrated sulfuric acid (concentration 93%) into a dilute sulfuric acid solution with a concentration of 20%, evenly spray wine on the straw treated in the previous step, store it for 2 days, take it out and dry it, and collect the remaining dilute sulfuric acid solution into a storage tank middle.

[0072] (4) Dissolve 4 kg of crude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com