Water-soluble fertilizer special for alkaline soil and its preparation method

A soil and water-soluble technology, applied in the direction of fertilizer mixture, application, fertilization device, etc., can solve the problems of not being mass-produced by enterprises, complex process operation, and limited application, etc., to achieve the increase of micronutrient elements, simple process flow, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

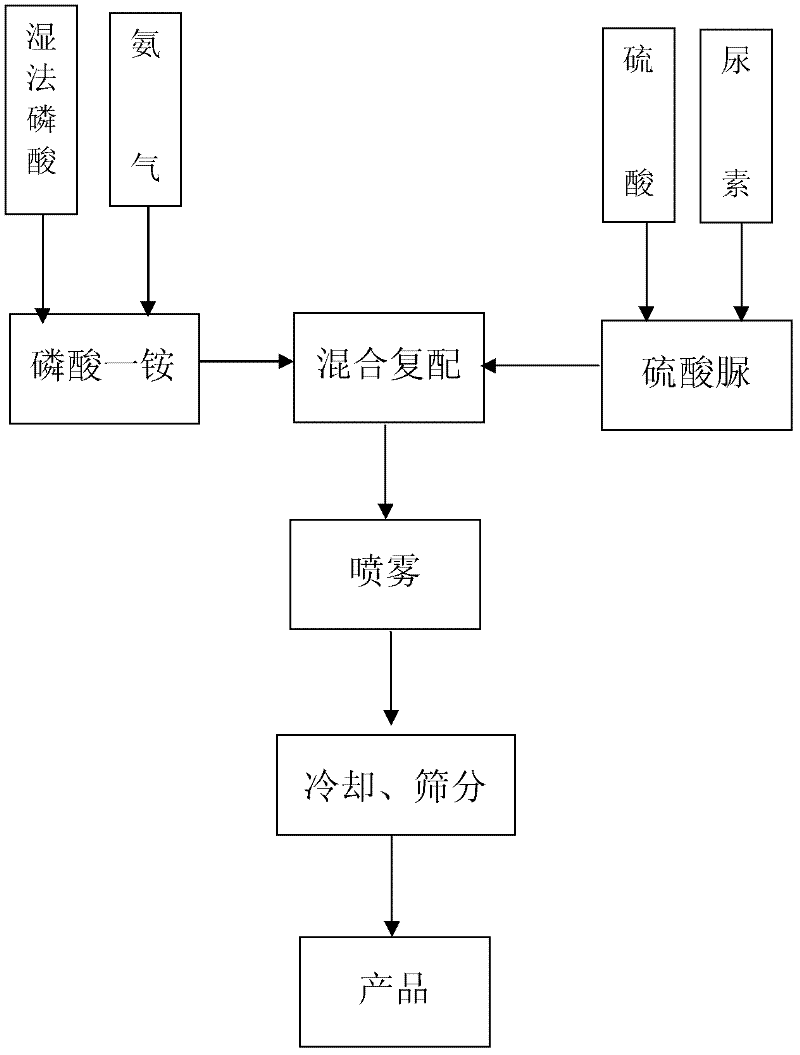

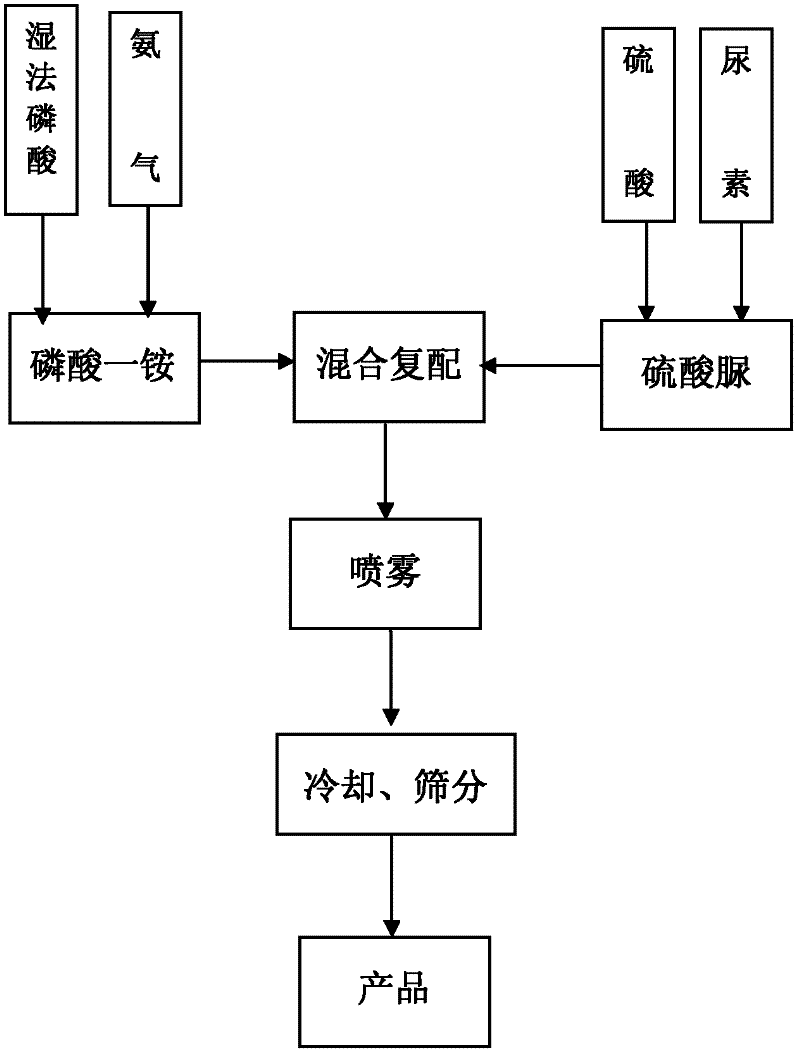

Method used

Image

Examples

Embodiment 1

[0042] The specific operation steps are as follows:

[0043] (1) Slowly add urea to the first reaction kettle with 98% sulfuric acid, start stirring, remove the heat of reaction released by the reaction while adding urea, control the slurry temperature in the reaction tank to be less than 100°C, and control the pH value At about 1, stop adding urea to obtain the first raw material urea sulfate slurry;

[0044] (2) Slowly feed ammonia gas into the second reaction kettle added with defluorinated wet-process phosphoric acid, and start stirring at the same time, when controlling the pH value between 4.2-4.6, stop feeding ammonia gas to obtain the second raw material phosphoric acid- Ammonium slurry;

[0045] (3) The raw materials prepared by the (1) step and the (2) step are mixed and compounded in the ratio of 40 parts by weight monoammonium phosphate: 60 parts of urea sulfate, and the proportion of the slurry is controlled between 1.33-1.43kg / L, Then it is input into the spray...

Embodiment 2

[0048] Concrete operation steps of the present invention are as follows:

[0049] (1) Slowly add urea into the first reaction kettle with 88wt% sulfuric acid, start stirring, remove the heat of reaction released by the reaction while adding urea, control the slurry temperature in the reaction tank to be less than 100°C, and control the pH value When about 1, stop adding urea, obtain the first raw material urea sulfate slurry;

[0050] (2) Slowly feed ammonia gas into the second reaction kettle added with defluorinated wet-process phosphoric acid, and start stirring at the same time, when controlling the pH value between 4.2-4.6, stop feeding ammonia gas to obtain the second raw material phosphoric acid- Ammonium slurry;

[0051] (3) The raw materials prepared in (1) step and (2) step are mixed and compounded in the ratio of 50 parts by weight monoammonium phosphate: 50 parts in urea sulfate, and the proportion of slurry is controlled between 1.33-1.43kg / L, Then it is input t...

Embodiment 3

[0054] Concrete operation steps of the present invention are as follows:

[0055] (1) Slowly add urea to the first reaction kettle with 98% sulfuric acid, start stirring, remove the heat of reaction released by the reaction while adding urea, control the slurry temperature in the reaction tank to be less than 100°C, and control the pH value At about 1, stop adding urea to obtain the first raw material urea sulfate slurry;

[0056] (2) Slowly feed ammonia gas into the second reaction kettle added with defluorinated wet-process phosphoric acid, and start stirring at the same time, when controlling the pH value between 4.2-4.6, stop feeding ammonia gas to obtain the second raw material phosphoric acid- Ammonium slurry;

[0057] (3) the raw materials prepared by the (1) step and the (2) step are mixed and compounded in the ratio of 75 parts by weight monoammonium phosphate: 25 parts of urea sulfate, and the proportion of the slurry is controlled between 1.33-1.43kg / L, Then it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com