Stone recrushing process

A secondary crushing and stone technology, applied in the field of stone crushing, can solve problems such as insufficient supply of raw materials, and achieve the effect of increasing output and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

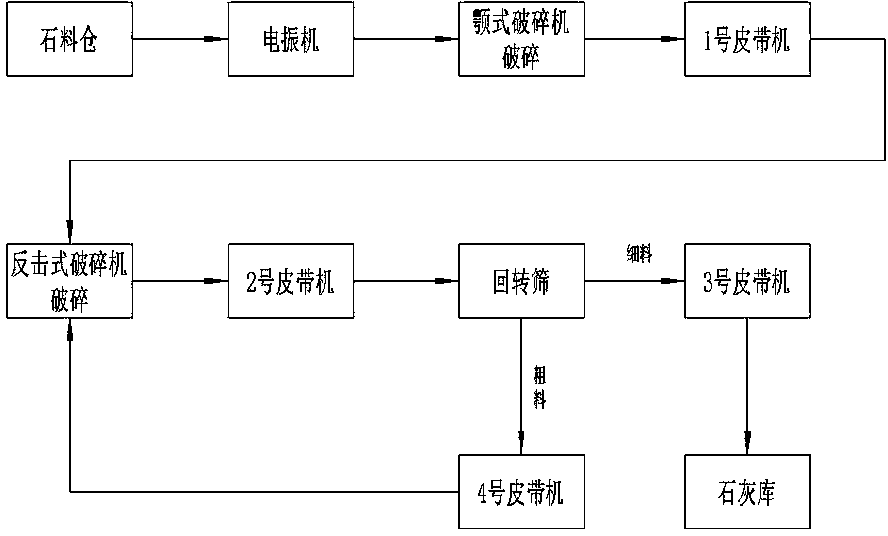

[0013] Below in conjunction with accompanying drawing, the present invention will be further described: figure 1 As shown, the process flow of the present invention is stone silo → electric vibration machine → jaw crusher crushing → No. 1 belt conveyor → impact crusher crushing → No. 2 belt conveyor → rotary screen, and the fine material is transported to the limestone warehouse through No. 3 belt conveyor The coarse material screened by the rotary screen is transported to the impact crusher for secondary crushing by the No. 4 belt conveyor, and then transported to the limestone storage by the No. 2 belt conveyor, rotary screen, and No. 3 belt conveyor to complete the stone processing process.

[0014] The limestone in the mine is transported to the stone silo, and the material is vibrated by the GZ8 electric vibrator, and then enters the PEF600mm×900mm collar crusher. After the primary crushing, the stone is sent to the Φ1250mm×1000mm impact crusher by the No. 1 B650 belt conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com