Device for rectifying and producing high-purity ethylene using ethylene heat pump, and high-purity ethylene production technology

A technology of heat pump rectification and high-purity ethylene, which is applied in lighting and heating equipment, solidification, refrigeration and liquefaction, etc. It can solve the problems of low thermal efficiency of rectification, failure to achieve high purity, and increased production cost, so as to improve energy utilization. , The product unit power consumption is low, and the effect of reducing product energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

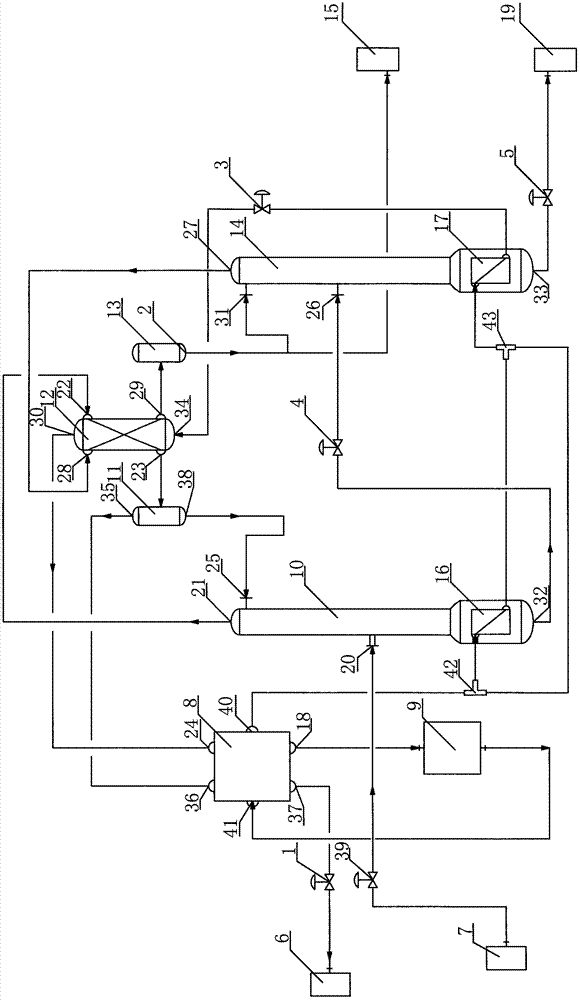

[0030] A device for producing high-purity ethylene by ethylene heat pump rectification, comprising a raw material liquid storage tank 7, a heat pump 9, an exhaust gas furnace 6, a by-product tank 19 and a product tank 15, and the raw material liquid storage tank 7 passes through a first throttling valve 39 and a second The first raw material liquid inlet 20 of a rectifying tower 10 is connected, and the gas phase outlet 21 at the top of the first rectifying tower 10 passes through the first raw material gas inlet 22 of the first heat exchanger 12, the first raw material of the first heat exchanger 12 The gas outlet 23 is connected to the inlet of the first gas-liquid separator 11, and the liquid phase outlet at the bottom of the first gas-liquid separator 11 is connected to the second feed liquid inlet 25 of the first rectification tower 10; The liquid phase outlet 32 is connected to the first raw material liquid inlet 26 of the second rectifying tower 14 through the second r...

experiment example

[0040] Technology of the present invention compares with the process method that adopts hydrocarbon pyrolysis, and it has obvious difference on energy consumption and product quality, specifically see the following table:

[0041] serial number Process method Product power consumption (comprehensive consumption) product quality 1 Hydrocarbon pyrolysis 2500KW / t ≥99% 2 this invention 1500KW / t ≥99.999%

[0042] It can be seen from the above table that the present invention is suitable for industrial scale production, and it mainly has the characteristics of low energy consumption and high product quality, and the product quality of the present invention can be improved to 99.999% electronic grade level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com