Phase change memory and manufacturing method thereof

A technology of phase change memory and manufacturing method, which is applied in the field of phase change memory and its manufacture, and can solve the problems that phase change memory cannot meet the application requirements of storage type memory, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

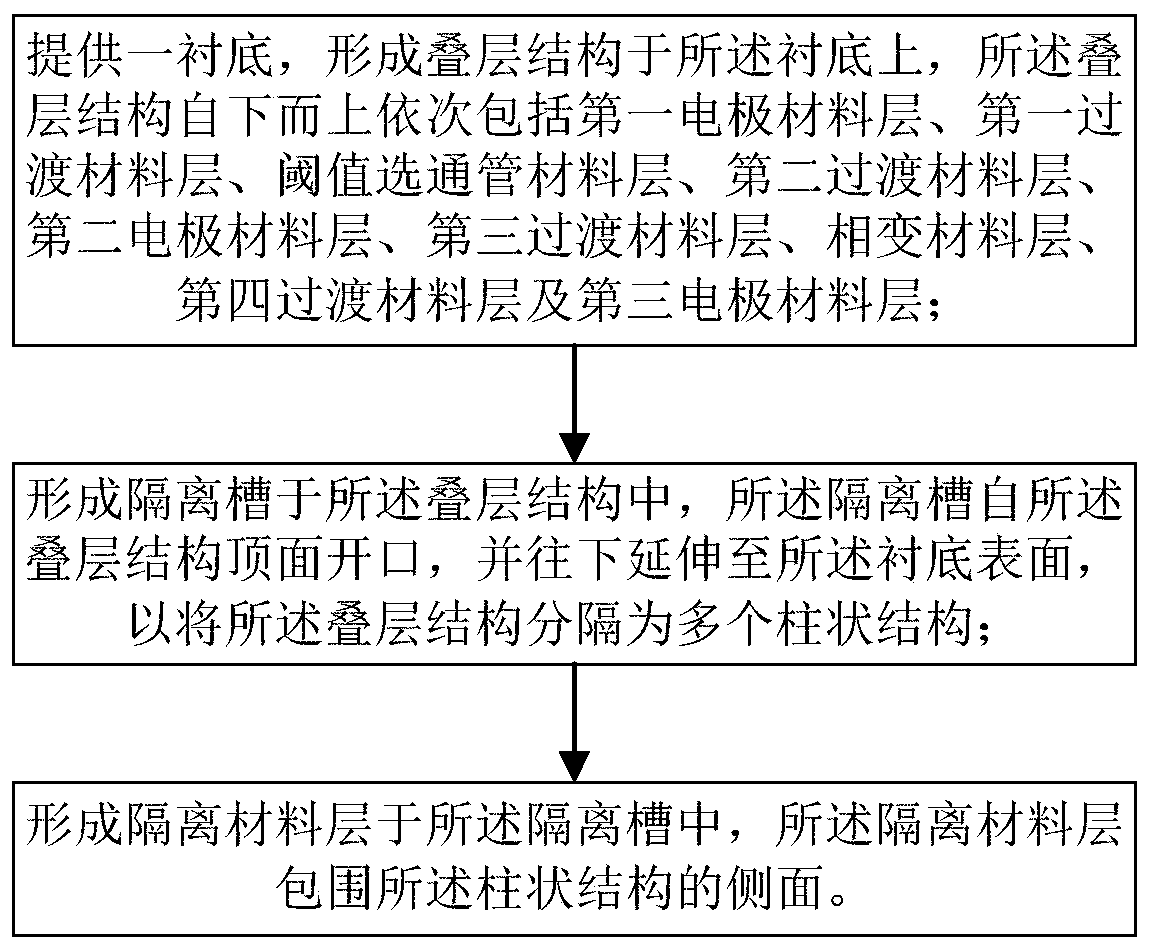

[0056] The present invention provides a manufacturing method of phase change memory, please refer to figure 1 , shown as a process flow diagram of the method, comprising the following steps:

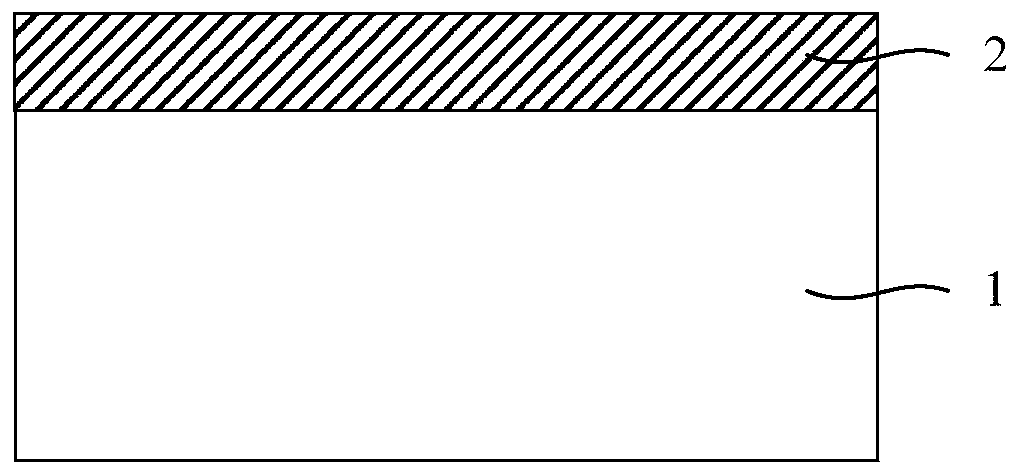

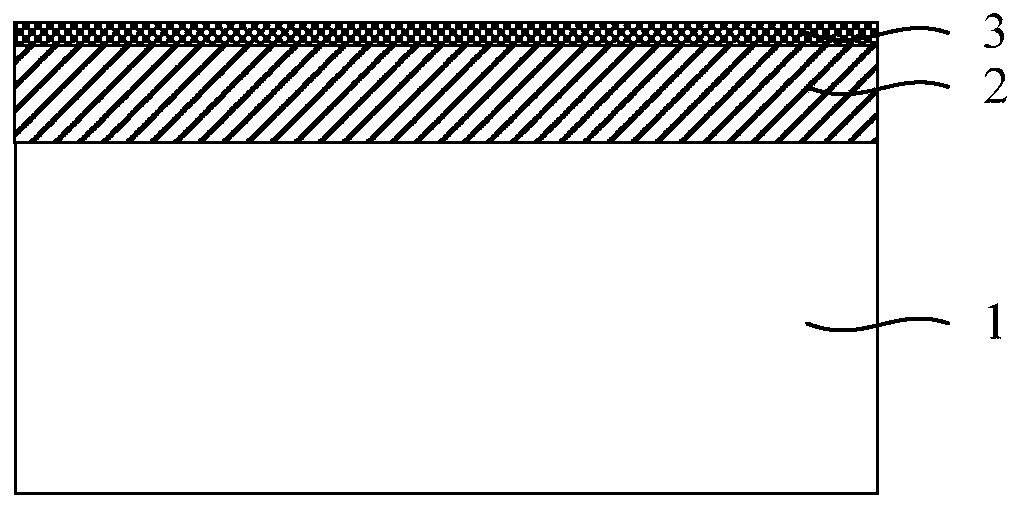

[0057] S1: Provide a substrate, and form a laminated structure on the substrate, the laminated structure sequentially includes a first electrode material layer, a first transition material layer, a threshold gate material layer, a second transition material layer, second electrode material layer, third transition material layer, phase change material layer, fourth transition material layer and third electrode material layer;

[0058] S2: forming isolation grooves in the stacked structure, the isolation grooves are opened from the top surface of the stacked structure, and extend down to the surface of the substrate, so as to separate the stacked structure into a plurality of columns structure;

[0059] S3: Form an isolation material layer in the isolation groove, the isolation material ...

Embodiment 2

[0091] The present invention also provides a phase change memory, please refer to Figure 12 , showing a schematic cross-sectional structure of the phase-change memory, including a substrate 1, an isolation material layer 12 and a plurality of phase-change memory cells, wherein the plurality of phase-change memory cells are separately arranged on the substrate 1, so The phase-change memory cell has a columnar structure, which includes a first electrode material layer 2, a first transition material layer 3, a threshold gate material layer 4, a second transition material layer 5, and a second electrode material layer 6 from bottom to top. , a third transition material layer 7, a phase change material layer 8, a fourth transition material layer 9 and a third electrode material layer 10; the isolation material layer 12 is located on the substrate 1 and surrounds the phase change memory unit Each of the phase change memory cells is isolated from each other by the isolation material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com