Air separation method capable of being matched with cold energy supply in receiving station

An air separation and matching technology, applied in the direction of cold treatment separation, refrigeration and liquefaction, liquefaction, etc., can solve the problems of insufficient cold energy, full utilization and impact of unstable LNG cold energy, etc., to reduce unit power consumption and obvious social benefits And economic benefits, the effect of high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

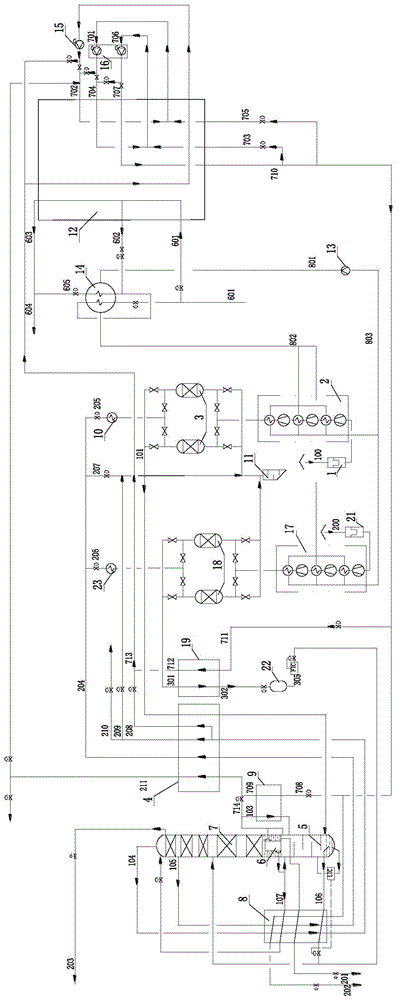

[0017] see figure 1 , an air separation method that can match the cold energy supply of the receiving station, comprising the following steps:

[0018] The first air 100 is inhaled through the air filter 1 and multi-stage compressed by the air compressor 2 (the coolers of each stage are cooled with ethylene glycol aqueous solution) to reach about 0.5 MPa, and then enters the air purifier 3 to remove harmful carbon dioxide, water, acetylene, etc. Impurities, compressed and purified first raw material air 101 is sent to the lower tower 5 of the air separation system.

[0019] The second air 200 is inhaled through the air filter 21 and compressed in multiple stages by the air compressor 17 (the coolers of each stage are cooled with ethylene glycol aqueous solution) to reach about 0.4MPa, and then enters the air purifier 18 to remove impurities such as carbon dioxide, water, and acetylene , the second raw material air 301 after compression and purification is sent to the air liqu...

Embodiment 2

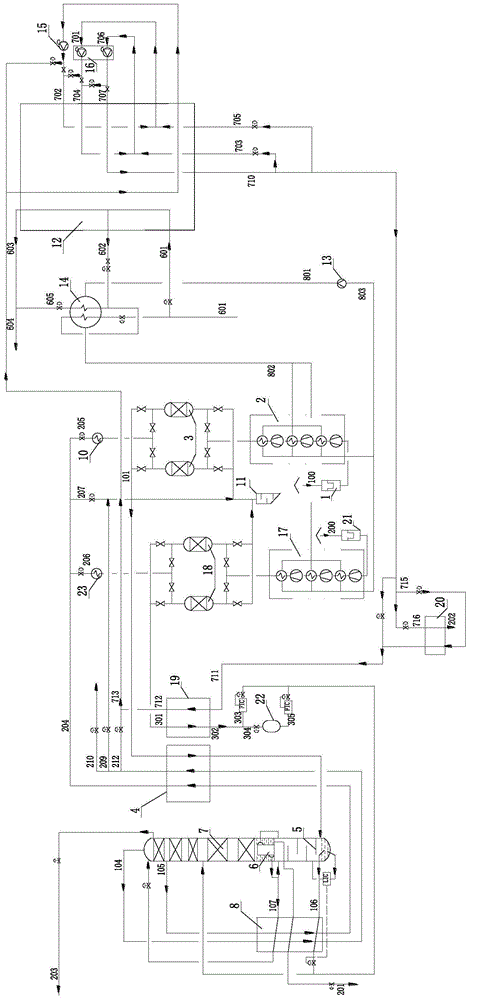

[0038] see figure 2 , an air separation method that can match the cold energy supply of the receiving station. The main difference from Example 1 is that in Example 1, liquid nitrogen is used to provide the required cooling capacity for air separation during the day, and liquid air is used for air separation at night. Air separation provides the required cooling and partly separates the air. And present embodiment then all is to provide required cooling capacity and part separated air for air separation with liquid air no matter daytime and night.

[0039] In the present embodiment, there is no liquid nitrogen-nitrogen heat exchanger 9, so there is no circulating pressure liquid nitrogen 708 and most of the liquid nitrogen product 202 for air separation from the LNG-nitrogen heat exchanger 12, nor is there any Pressure nitrogen 103 and nitrogen 714 drawn from the top.

[0040] In the daytime, one strand is drawn from the high-pressure supercooled liquid nitrogen 710 as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com