Pendulum type all-purpose flour mill

A milling machine, an all-round technology, applied in solid separation, separating solids from solids with airflow, grain processing, etc., can solve the problems of expensive sorting equipment and increase product cost, so as to improve grinding efficiency and prolong Effects of service life, increased strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

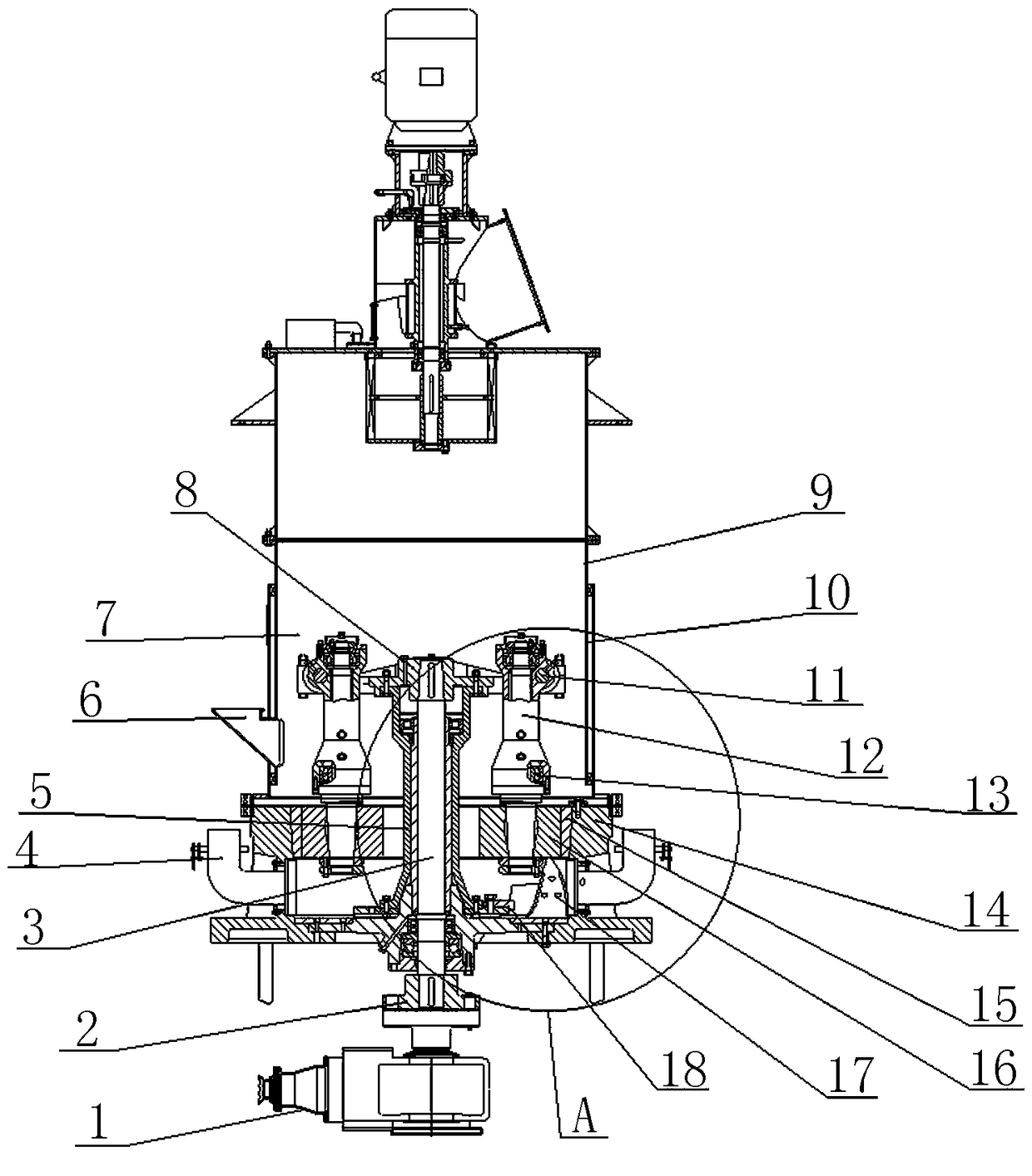

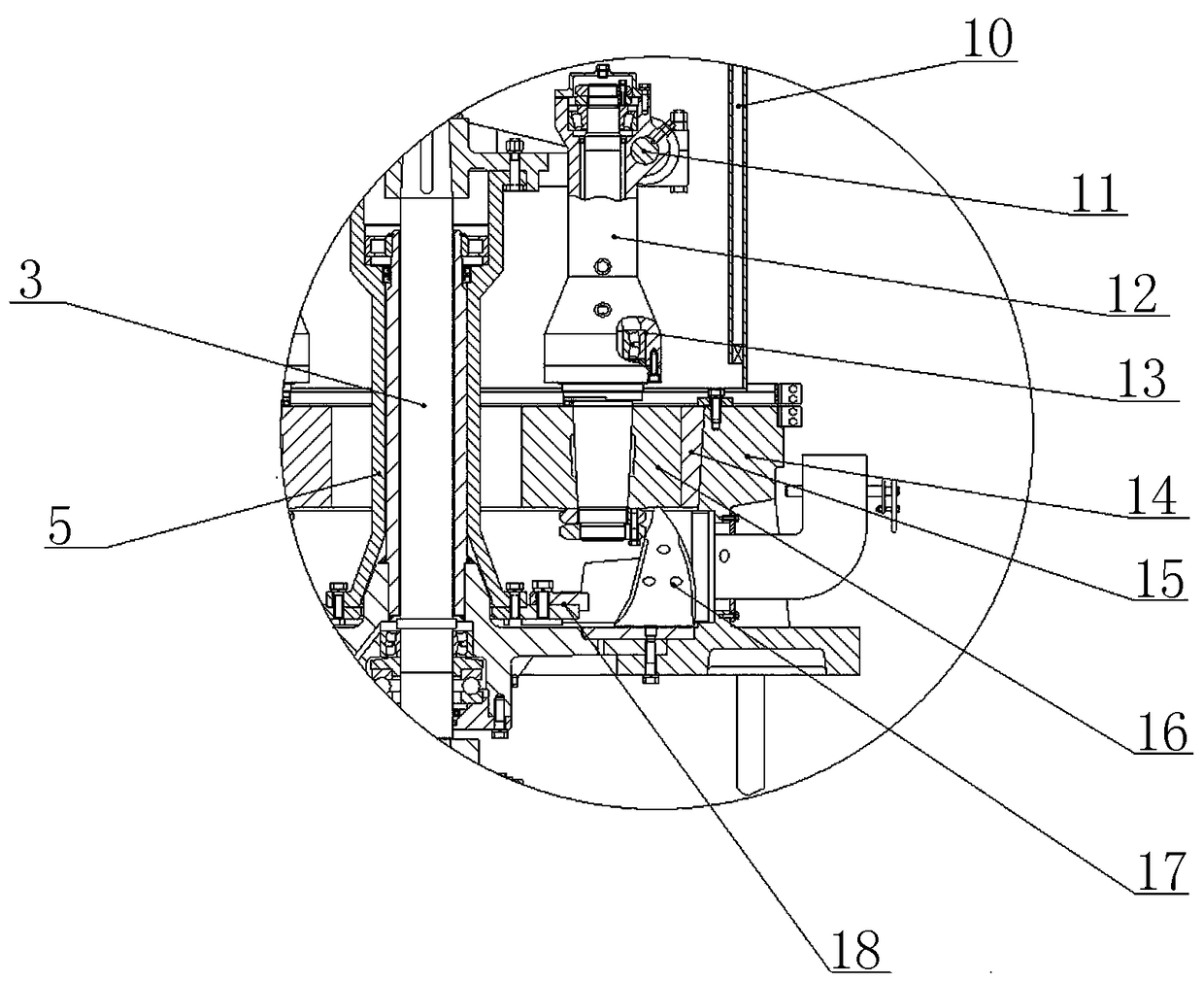

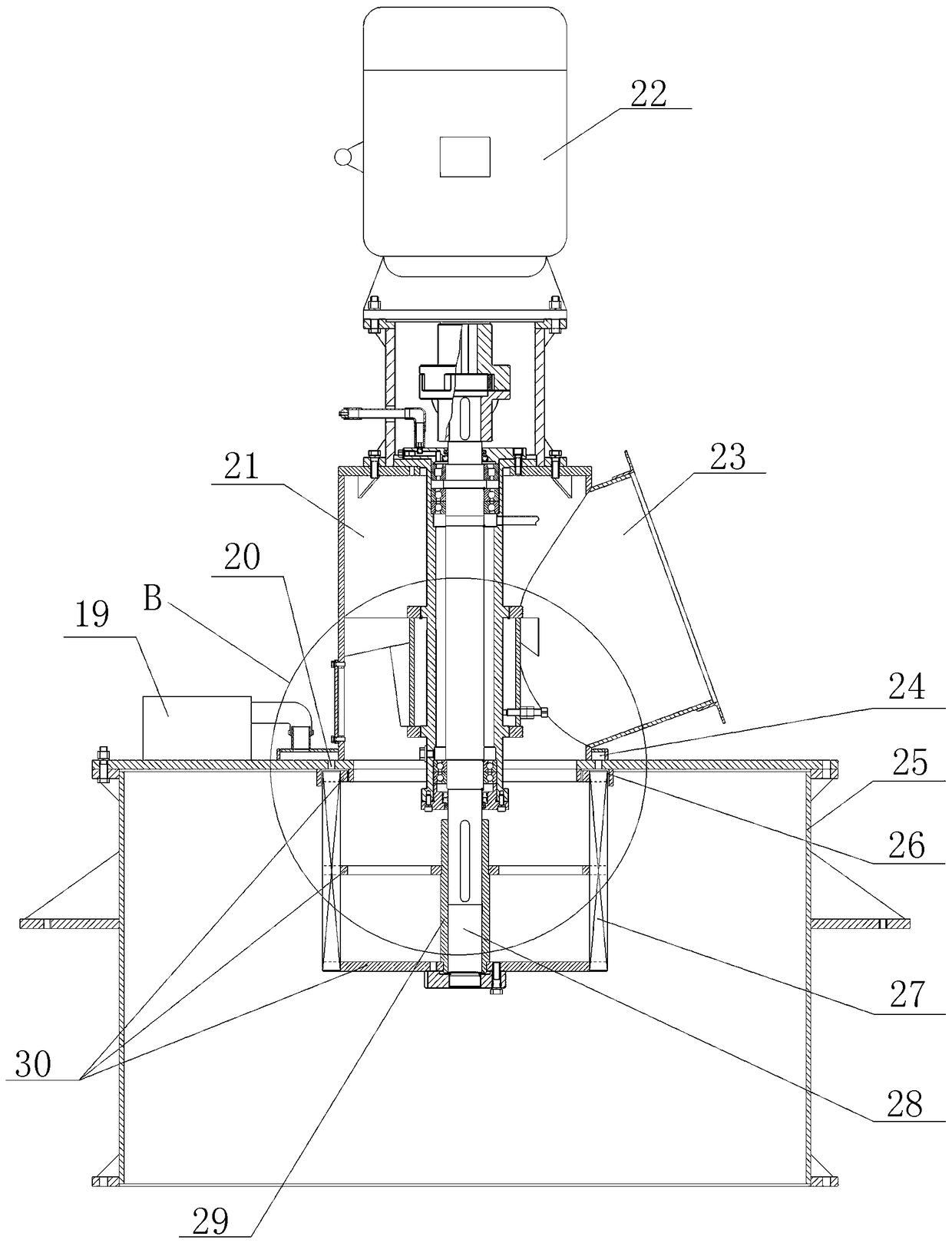

[0031] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown in the figure, a pendulum universal mill includes a milling host and a classifier;

[0032] The milling host includes a cylinder 9, a central rotating main shaft 3 and a grinding roller device, the cylinder 9 is installed on the base 14, and the wall of the cylinder 9 is provided with a feeding port 6; inside the cylinder 9 is a powder mill. Chamber 7, the central rotating main shaft 3 is installed in the center of the grinding chamber 7 and the base 14; the lower end of the central rotating main shaft 3 protrudes from the base 14 and is connected with the power mechanism reducer 1 through the coupling 2, and the upper end of the central rotating main shaft 3 is equipped with a plum blossom frame 8 , more than 2 groups of cross-arm shafts 11 are evenly distributed on the plum frame 8; the grinding roller device includes a grinding roller 16, a grinding roller shaft 12 and a grinding roller sleeve 13; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com