Device and method for manufacturing dry ice by using liquefied natural gas cold energy

A technology for liquefied natural gas and production equipment, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve uninvolved problems, achieve easy transportation and centralized processing, save cooling water and electricity consumption, obvious environmental and economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

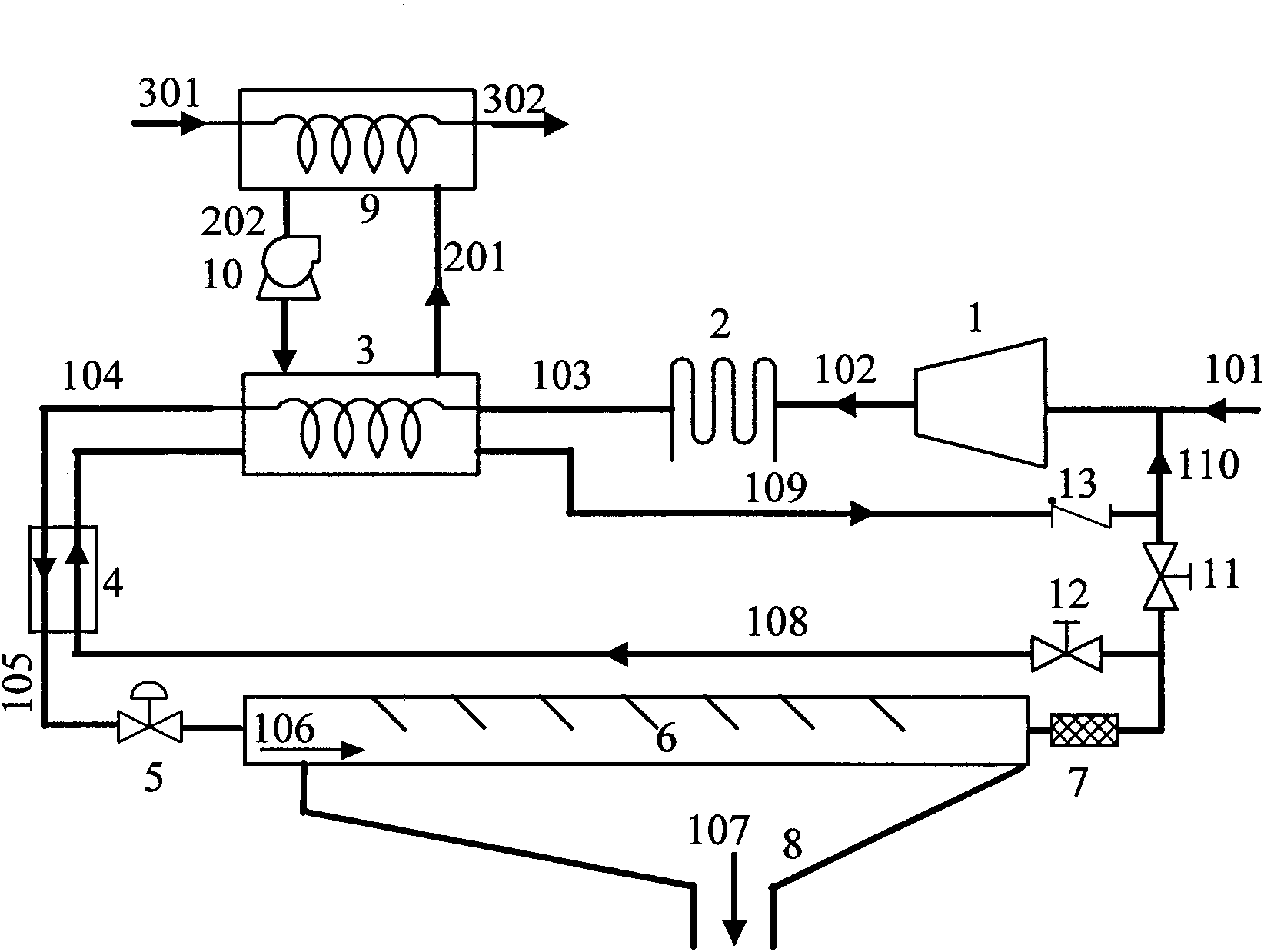

[0017] Such as figure 1 As shown, the dry ice production plant using the cold energy of liquefied natural gas includes CO 2 Gas compressor 1, water cooler 2, propane heat exchanger 3, cryogenic heat exchanger 4, throttle valve 5, dry ice collector 6, filter screen 7, funnel 8, natural gas heat exchanger 9, cryogenic pump 10, bypass Valve 11, stop valve 12, check valve 13; CO 2 Gas compressor 1 outlet and water cooler 2, propane heat exchanger 3 high temperature channel, high pressure coil of low temperature heat exchanger 4, throttle valve 5, dry ice collector 6, filter screen 7, stop valve 12, low temperature heat exchanger 4 low pressure coils, propane heat exchanger 3 low temperature channels, check valve 13, CO 2 The inlets of the gas compressor 1 are connected sequentially; a bypass valve 11 is provided between the stop valve 12 and the check valve 13; a funnel 8 is provided below the dry ice collector 6; The shell side of the heat exchanger 9 is connected to the inlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| triple point temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com