Evaporation crystallization method for treating salt-containing wastewater and device for implementing method

A technology of salty wastewater and evaporative crystallization, which is applied in the field of MVR evaporative crystallization system, can solve the problems of smaller heat transfer temperature difference, easy scaling, and reduced evaporation efficiency of evaporator, so as to reduce heat exchange temperature difference and improve anti-scaling. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

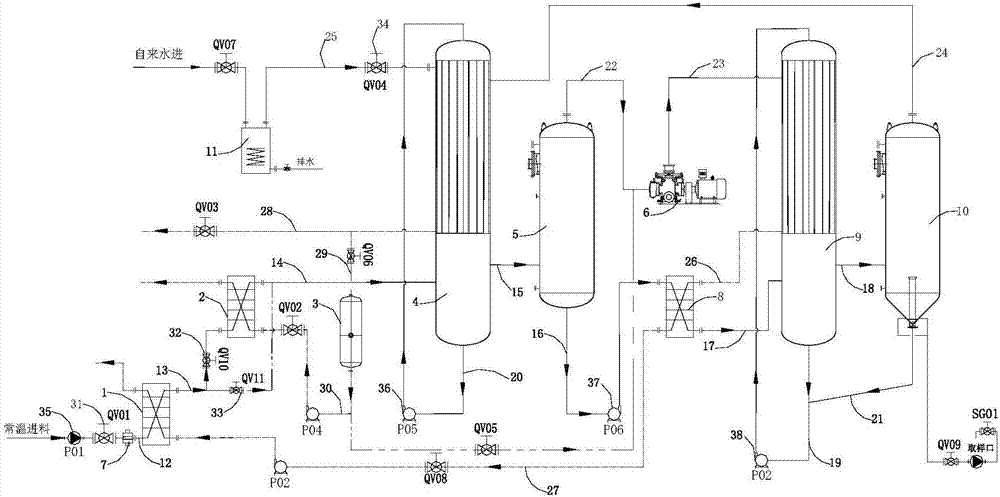

[0042] use as figure 1 The device shown in the treatment of high-concentration saline wastewater includes the following steps:

[0043] (1) Nacl waste water produced by chemical industry, food and other industries, with a mass concentration of 5%, passes through the electromagnetic wave emitting device, the first material delivery pipeline 12, and then enters the primary preheater 1 for preliminary preheating, and then passes through the second material The conveying pipeline 13 enters the secondary preheater, is heated to 78°C, and then enters the second-effect falling film evaporator 4 through the third material conveying pipeline 14, mixes with the bottom material and evaporates, and the second-effect falling film evaporator The pressure is 47.4Kpa, and the mass concentration of the material reaches 9.5%. During this process, the material is always in a low-concentration state, and the boiling point of the material is the same as that of ordinary water. The conveying pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com