Air separation method utilizing cold energy of liquefied natural gas

A technology of liquefied natural gas and cold energy, applied in liquefaction, refrigeration, liquefaction, solidification, etc., can solve problems such as underutilization of high-temperature cold energy, high shaft power of compressors, and high shaft power of raw material air compressors, and achieve obvious social benefits And economic benefits, unit power consumption reduction, cooling water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

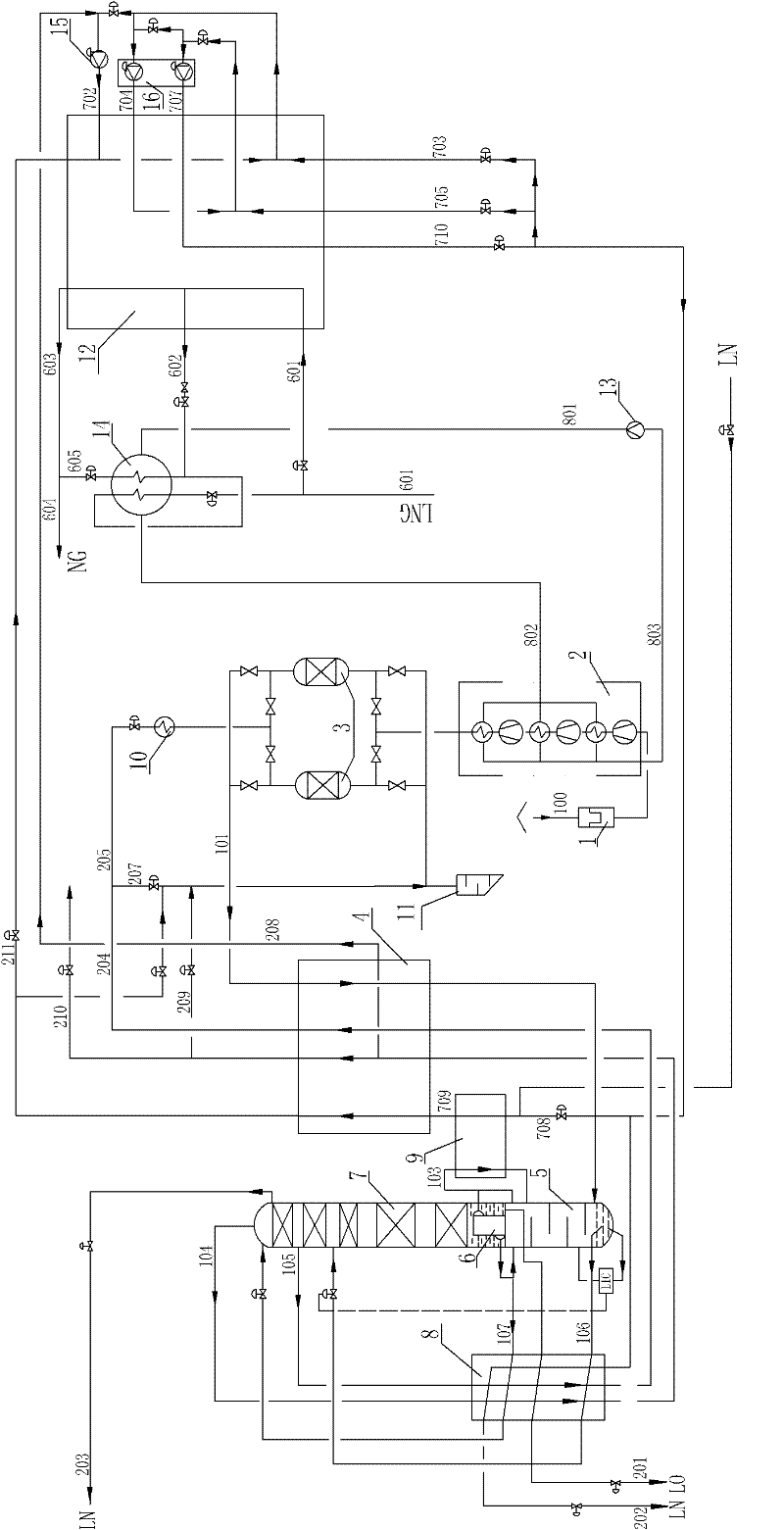

[0026] see figure 1 , a kind of air separation method utilizing the cold energy of liquefied natural gas of the present invention:

[0027] Raw material air 100 is inhaled through air filter 1 and multi-stage compressed by air compressor 2 (the coolers at each stage are cooled by circulating coolant) to about 0.5 MPa, and then enters air purifier 3 to remove harmful impurities such as carbon dioxide, water, and acetylene, and purify The final compressed feed air 101 is sent to the air separation unit.

[0028] The purified compressed raw air 101 is sent to the lower tower 5 after the main heat exchanger 4 exchanges heat with the reflux gas and cools down to the required temperature. After the air is preliminarily separated in the lower towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com