Combined holder for ore furnace

A combined type and controller technology, applied in the direction of electric heating devices, heating through discharge, electrical components, etc., can solve problems such as easy deformation, high maintenance costs, and damage to copper tiles caused by arcing, and achieve improved conductivity and lower unit power consumption. The effect of falling and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

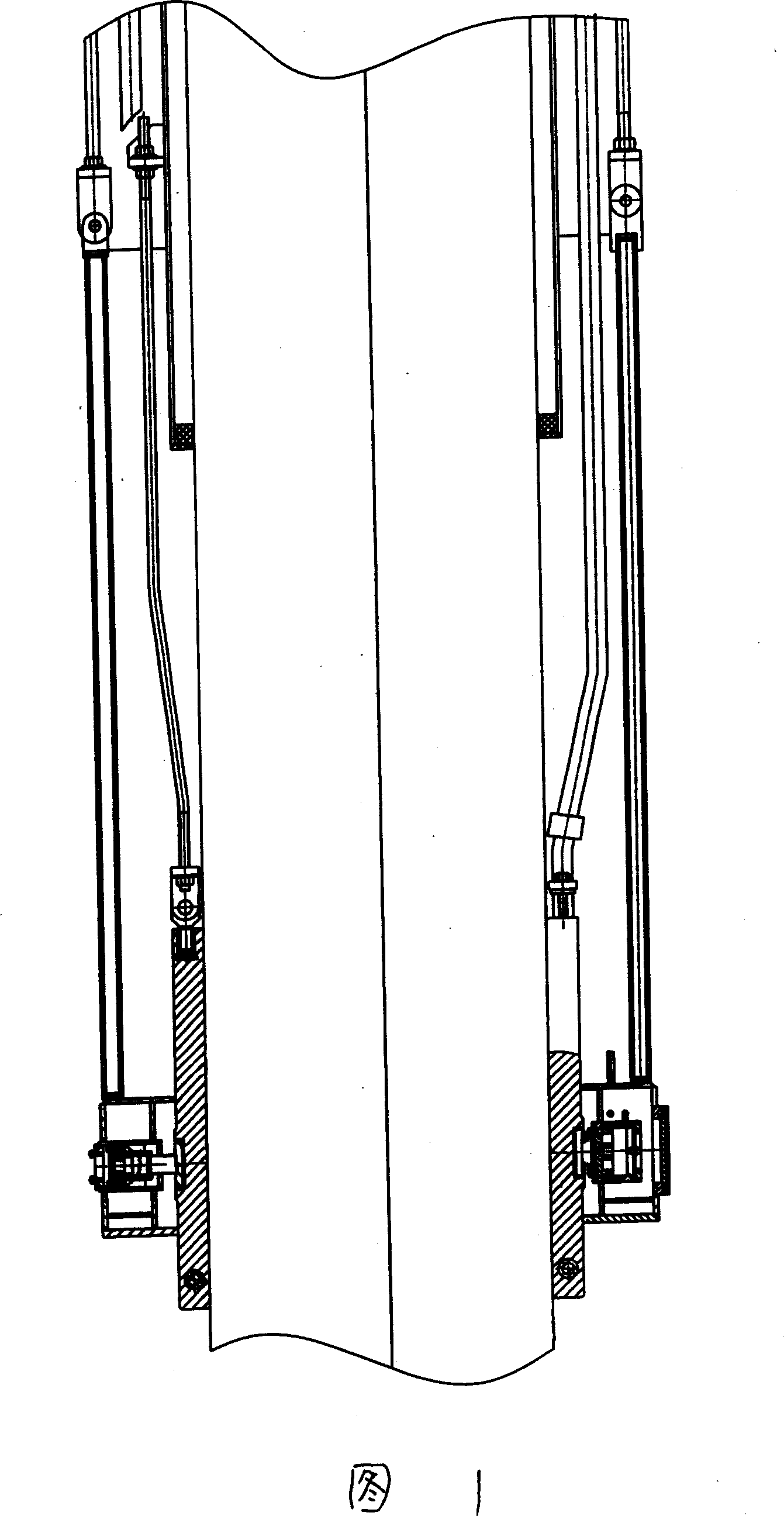

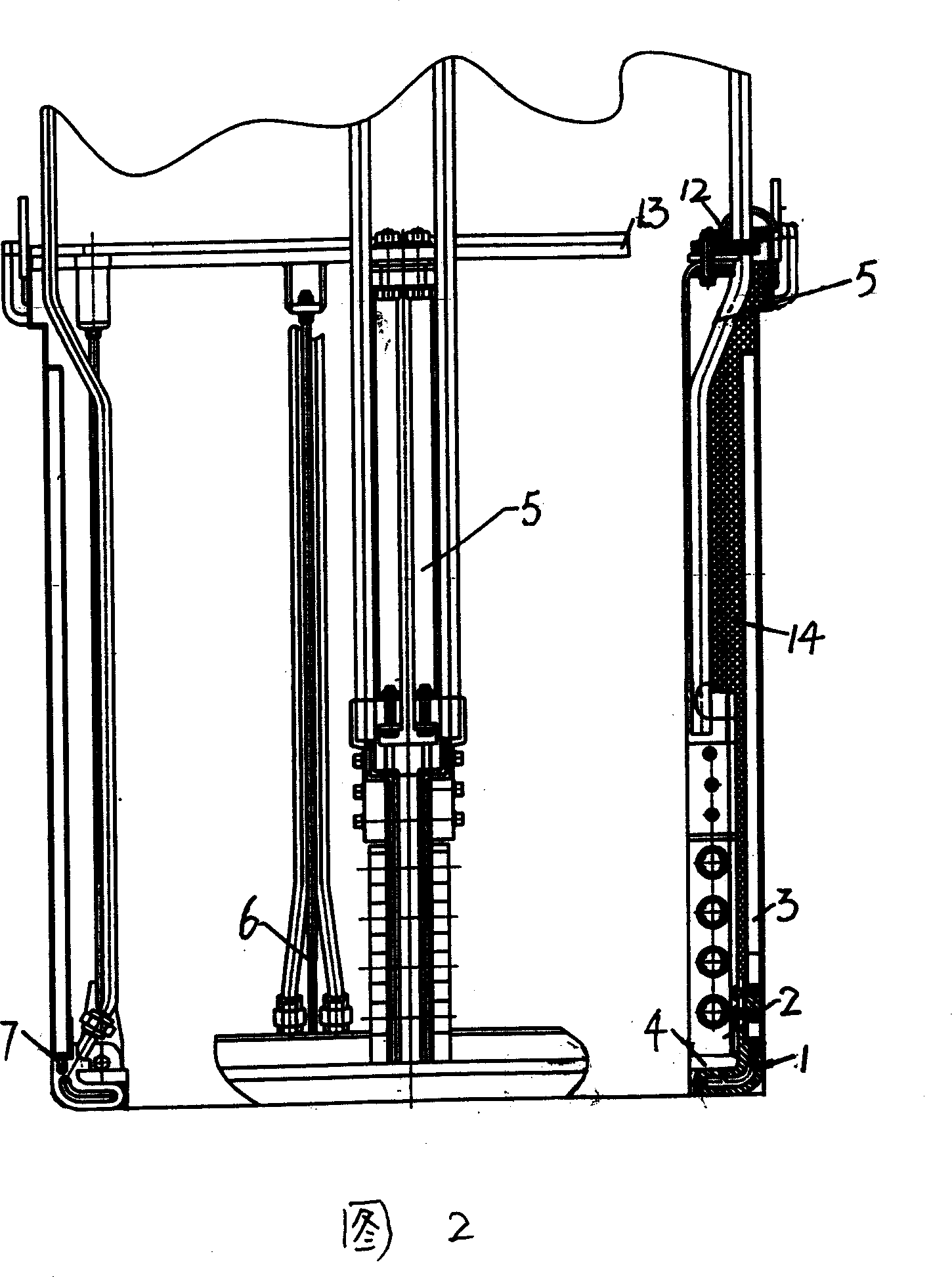

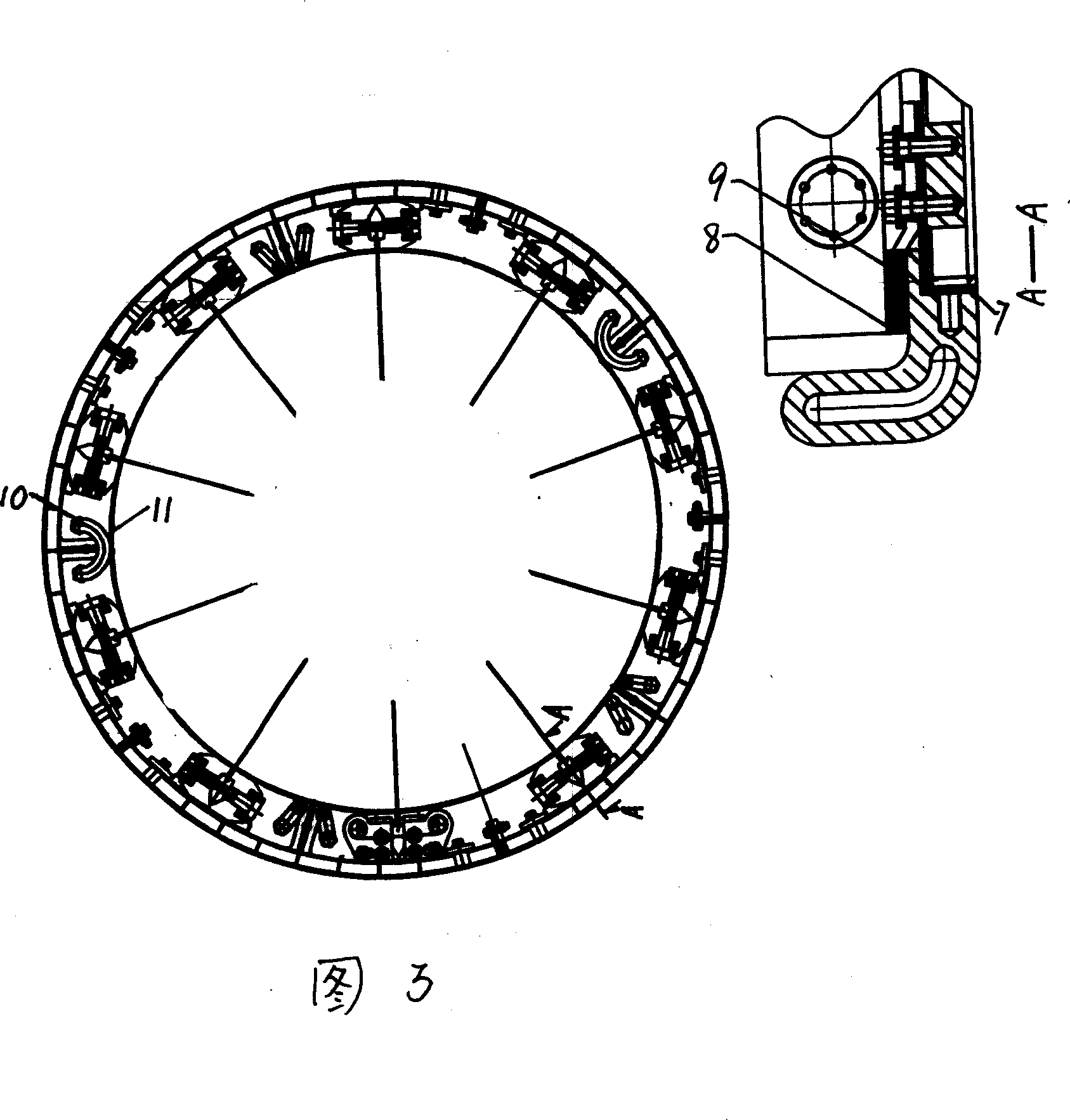

[0014] Combined holder for submerged arc furnace, the electrode shell 11 is welded by several arc plates and ribs 14, the two sides of the outer ribs of the electrode shell 11 are equipped with conductive element groups 2 that are fixedly connected by adjusting bolts and butterfly springs. The top of the component group 2 is fixed on the flange 13 of the holding cylinder by a stainless steel bent plate 5, and the bottom end is seated on the bottom ring 1. A high-temperature heat-insulating sealing plate 4 is arranged between the conductive component group 2 and the bottom ring 1, and the bottom ring 1 passes through the suspension rod. 6. It is fixed on the flange 13 of the holding cylinder. The conductive element group 2 is provided with a stainless steel protective sleeve 3 outside. The stainless steel protective sleeve 3 and the electrode shell 11 are filled with heat insulating material 14. The bottom of the stainless steel protective sleeve 3 is plugged into the bottom by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com