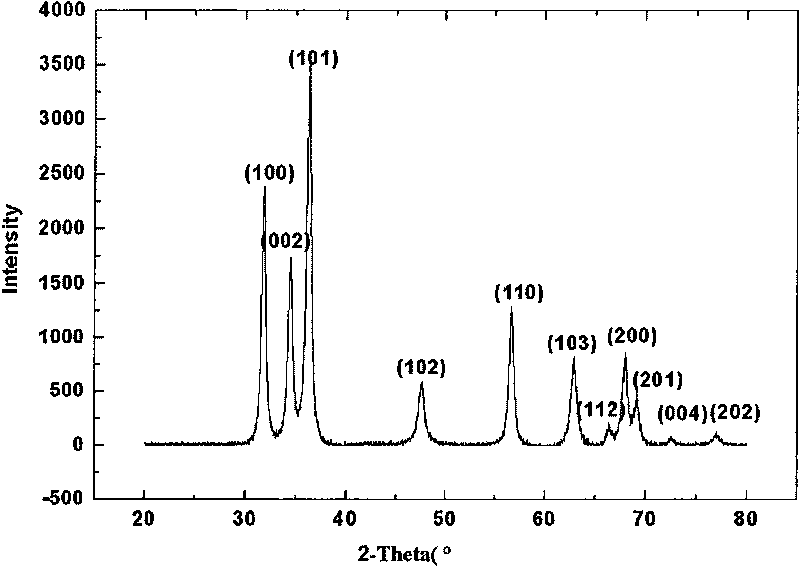

Controllable method for preparing nano zinc oxide powder

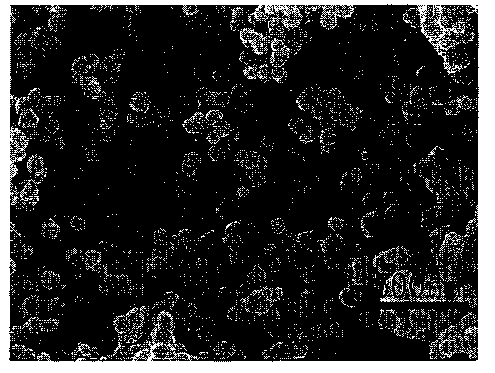

A technology of nano-zinc oxide powder and zinc nitrate, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of corrosion of reaction equipment, increased production difficulty, rare nano-powder, etc., and achieve good dispersion, uniform particle size and reliable Control and process flow are reasonable and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] 1. Weigh 8.9247g of zinc nitrate and 6.304g of citric acid, dissolve them in 50mL of deionized water to form a solution of zinc nitrate and citric acid with a molar ratio of 1:1, then stir magnetically for 30 minutes until completely dissolved to form a transparent and colorless solution . Weigh 6g polyethylene glycol 2000, dissolve it in 50mL deionized water to form a 0.3mol / L zinc nitrate solution, stir it magnetically for 30 minutes to form a transparent solution, then add the polyethylene glycol solution to the citric acid solution, the pH The value is 1.

[0022] 2. The mixed solution of zinc nitrate, citric acid, and polyethylene glycol 2000 was transferred to a three-necked flask, stirred in a water bath at 85°C, condensed and refluxed for 4 hours through a condenser, and naturally cooled to room temperature for 4 hours.

[0023] 3. The transparent sol was transferred to a jacketed glass reactor and gelled at 85°C to obtain a colorless transparent gel.

[0024]...

example 2

[0027] 1. Weigh 8.9247g of zinc nitrate and 6.304g of citric acid, dissolve them in 50mL of deionized water to form a solution of zinc nitrate and citric acid, the molar ratio is 1:1.5, and then stir magnetically for 30 minutes until completely dissolved to form a transparent and colorless solution . Weigh 6 g of polyethylene glycol 2000, dissolve it in 50 mL of deionized water to form a 0.3 mol / L zinc nitrate solution, stir it magnetically for 30 minutes to form a transparent solution, and then add the polyethylene glycol solution to the citric acid solution.

[0028] 2. Adjust the pH value to 7 with ammonia water.

[0029] 3. The mixed solution of zinc nitrate, citric acid, and polyethylene glycol 2000 was transferred to a three-necked flask, stirred in an 85°C water bath, condensed and refluxed through a condenser for 4 hours, and naturally cooled to room temperature for 4 hours.

[0030] 4. The transparent sol was transferred to a jacketed glass reactor and gelled at 85°C...

example 3

[0034] 1. Weigh 8.9247g of zinc nitrate and 6.304g of citric acid, dissolve them in 50mL of deionized water to form a solution of zinc nitrate and citric acid, the molar ratio is 1:1.5, and then stir magnetically for 30 minutes until completely dissolved to form a transparent and colorless solution . Weigh 6g polyethylene glycol 2000, dissolve it in 50mL deionized water to form a 0.3mol / L zinc nitrate solution, stir it magnetically for 30 minutes to form a transparent solution, then add the polyethylene glycol solution to the citric acid solution, the pH The value is 1.

[0035] 2. The mixed solution of zinc nitrate, citric acid, and polyethylene glycol 2000 was transferred to a three-necked flask, stirred in a water bath at 85°C, condensed and refluxed for 4 hours through a condenser, and naturally cooled to room temperature for 4 hours.

[0036] 3. The transparent sol was transferred to a jacketed glass reactor and gelled at 85°C to obtain a colorless transparent gel.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com