A preparation method of high dielectric copper/polyvinylidene fluoride composite material

A polyvinylidene fluoride and composite material technology, which is applied in the field of preparation of high-dielectric copper/polyvinylidene fluoride composite materials, can solve the problems of large dielectric loss, small copper particles, high density, etc., and achieves low cost and improved dispersion. The effect of the properties and the simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A high dielectric copper / polyvinylidene fluoride composite material, specifically comprising the steps of:

[0031] S1. Weigh 0.6g of polyvinylidene fluoride and 3mL of N,N-dimethylformamide, stir and dissolve at room temperature into a transparent viscous liquid;

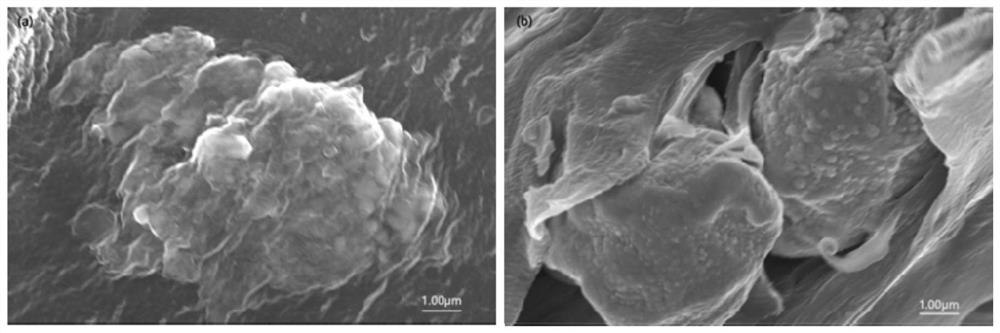

[0032] S2. Weigh 0.335g of copper powder and 0.00763g of L-cysteine, then add 3mL of N,N-dimethylformamide, and sonicate for 20min;

[0033] S3. Transfer the viscous liquid in S1 to S2, and after stirring at room temperature for 1 hour, take out the stirring bar, vacuumize, and remove the air in the sol;

[0034] S4. Cast the sol onto a preheated glass sheet, scrape it flat with a scraper, put it in a vacuum oven at 150° C., evacuate, heat at a constant temperature for 1 hour, and then cool to room temperature to obtain a copper / polyvinylidene fluoride film.

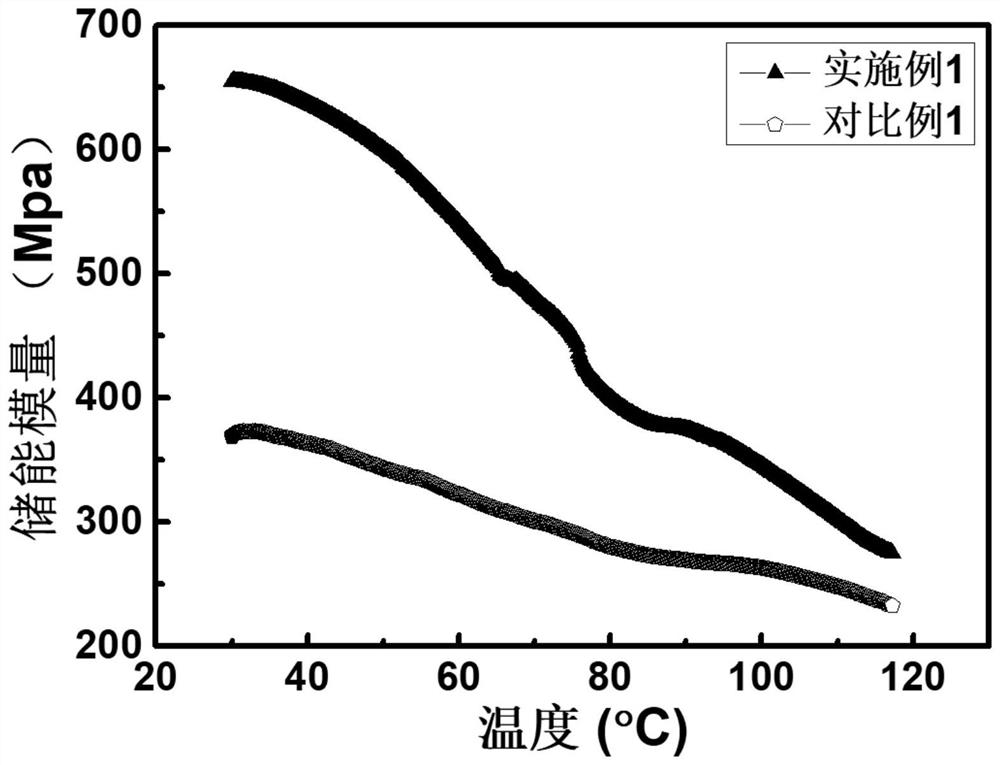

[0035] At room temperature, the dielectric constant of the composite material prepared in this embodiment at 100 Hz was 19.09, and the dielectric los...

Embodiment 2

[0045] A high dielectric copper / polyvinylidene fluoride composite material, specifically comprising the steps of:

[0046] S1. Weigh 0.6g of polyvinylidene fluoride and 3mL of N,N-dimethylformamide, stir and dissolve at room temperature into a transparent viscous liquid;

[0047] S2. Weigh 0.754g of copper powder and 0.0153g of L-cysteine, then add 3mL of N,N-dimethylformamide, and sonicate for 20min;

[0048] S3. Transfer the viscous liquid in S1 to S2, and after stirring at room temperature for 1 hour, take out the stirring bar, vacuumize, and remove the air in the sol;

[0049] S4. Cast the sol onto a preheated glass sheet, scrape it flat with a scraper, put it in a vacuum oven at 150° C., evacuate, heat at a constant temperature for 1 hour, and then cool to room temperature to obtain a copper / polyvinylidene fluoride film.

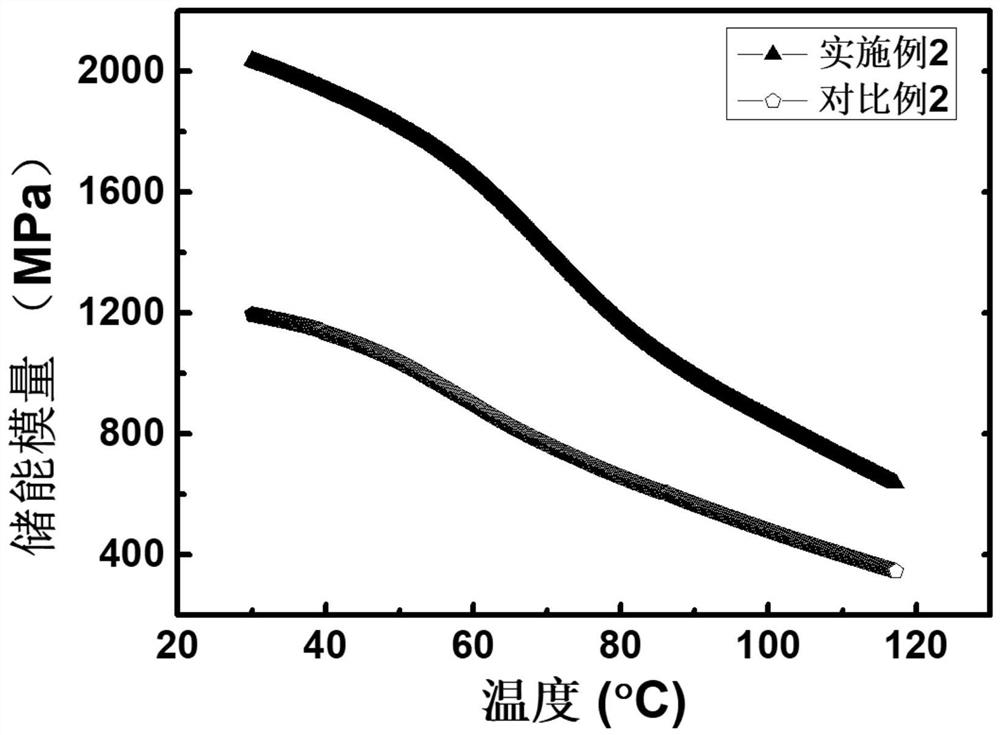

[0050] At room temperature, the dielectric constant of the composite material prepared in this experimental example was 33.91 at 100 Hz, and the diele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com