Patents

Literature

33results about How to "Easy to operate and produce" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polythioetherimide and preparation method thereof

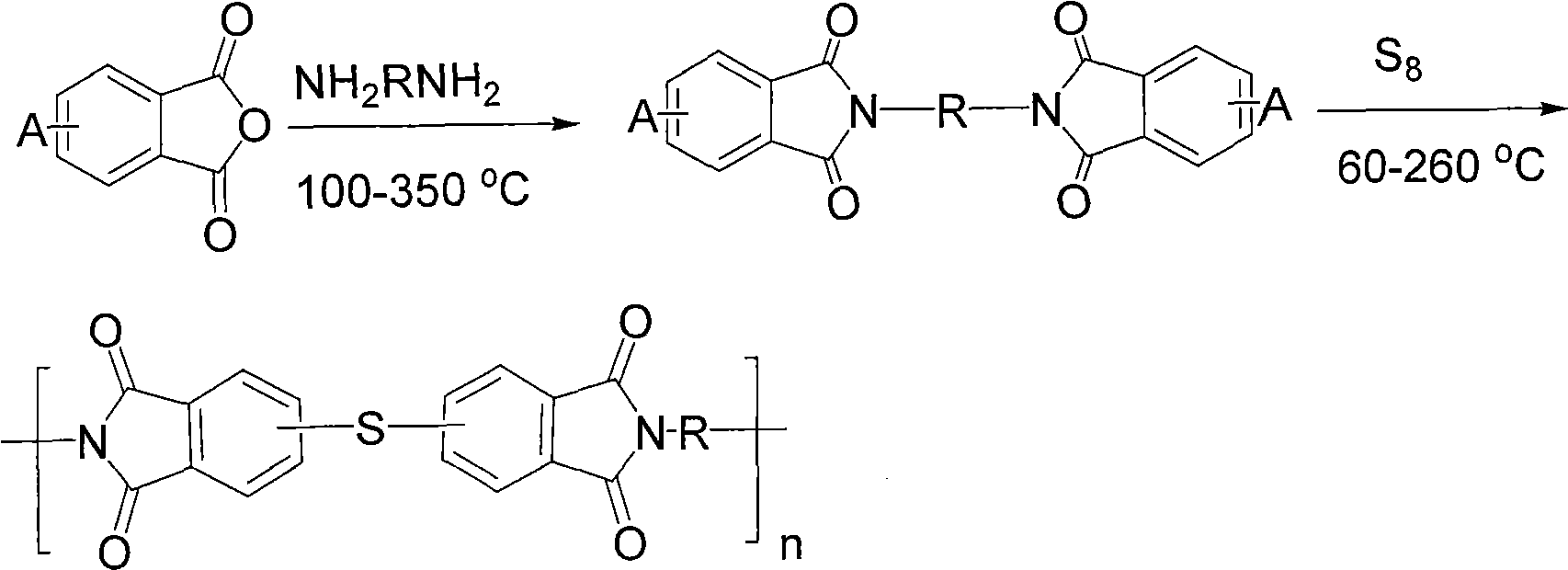

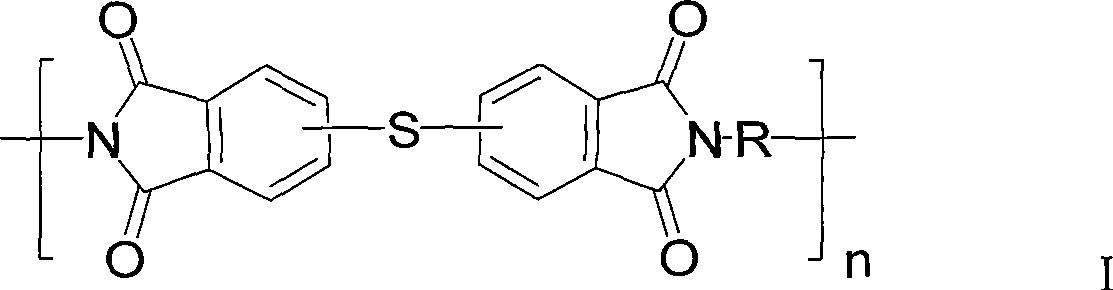

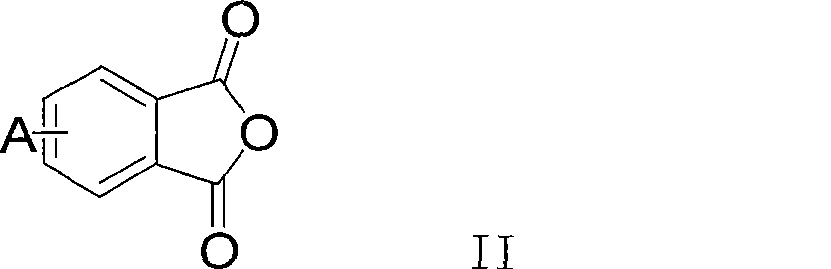

The invention relates to polythioetherimide and a preparation method thereof. The method is characterized by comprising the following steps: mono-substituted phthalic anhydride isomer with structural formula II is adopted as a reaction material to react with organic diamine NH2RNH2 with half mol equivalent weight at the temperature of about 100 DEG C to about 350 DEG C to generate binary-substituted phthalimide; then binary-substituted phthalimide and sulfur with about equimolar equivalent weight are subjected to coupling polymerization reaction at the temperature of about 60 DEG C to about 260 DEG C under the existence of reducing agent, catalyst and reaction auxiliary agent to generate polythioetherimide resin with structural formula I; and the molecular weight of the resin can be adjusted by end capping agent. The preparation method can greatly reduce the preparation cost and reaction steps, the whole process is more reasonable and practical, and the obtained resin has superior comprehensive properties such as good heat resistance, mechanical properties, melting processing property and the like, can be widely applied in the related fields such as high-temperature resistant engineering plastics, films, adhesives, enameled wires, foamed plastics, fiber, advanced composite materials and the like; in the structural formula II, A substituent is chlorine atom or nitro at 3-bit or 4-bit; and in the structural formula I, R is substituted or unsubstituted organic group.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

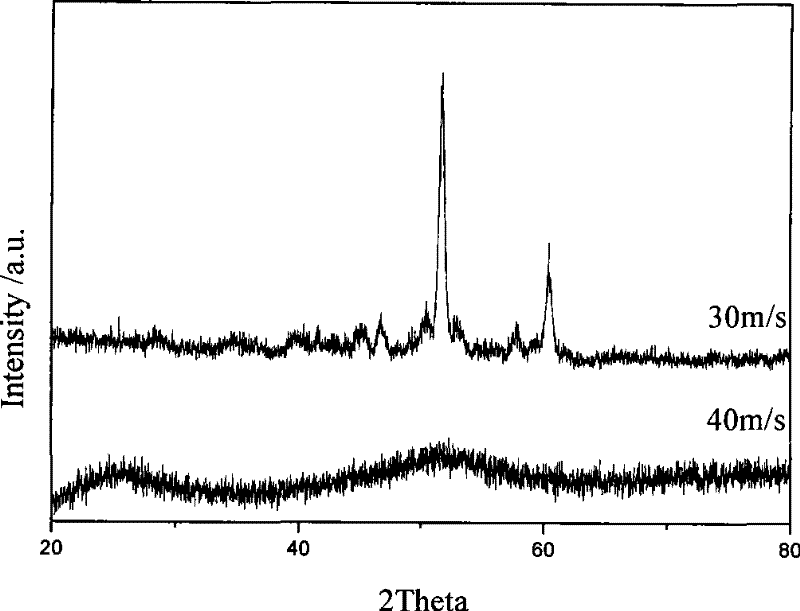

Controllable method for preparing nano zinc oxide powder

InactiveCN101734709AEasy to operate and produceEasy to implementZinc oxides/hydroxidesWater bathsPolyvinyl alcohol

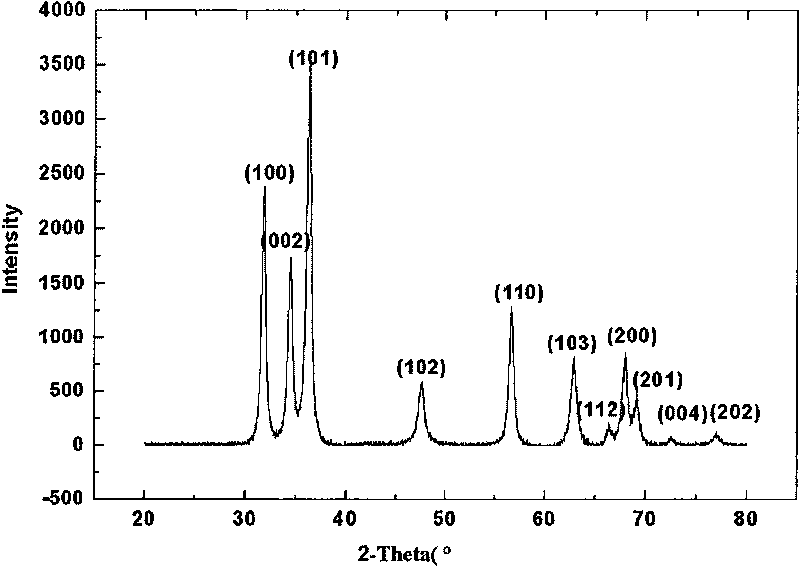

The invention relates to a controllable method for preparing nano zinc oxide powder, which is characterized by adopting the salt of inorganic zinc nitrate and the chelating agent of citric acid which has the complexing function as the raw materials and the ethylene glycol, the polyethylene glycol, or the polyvinyl alcohol as the surfactant. The controllable method for preparing the nano zinc oxide powder specifically comprises the following steps: preparing solution from the zinc nitrate, the citric acid and the surfactant according to a certain molar ratio, reflowing the solution with water bath, aging, gelatinizing, drying and annealing to obtain the nano zinc oxide powder with single component and uniform distribution of the agglomeration-free particle of 20-100 nm. The nano zinc oxide powder has low cost, high quality and high yield, is prepared with simple equipment and can realize the industrial production easily.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for improving recovery of hematite and limonite

The invention relates the method for Improving the red hematite and brown hematite recovery ratio. The method of solving low recovery ratio of red hematite and brown hematite comprises the following steps: treating the non-magnetic iron ore to magnetic ore, and then dressing ore with magnetic method. The invention method comprises the following step: disintegrating the ore with crusher, high-temperature roasting, making it form magnetic ore, adding water, and then dressing ore with magnetic method. The method has the advantages of simple operation, high Fe2O3 ore recovery ratio and great economic benefit.

Owner:张志发

Glaze for achieving silk glazed surface effect on tile surface, preparation method and tile

InactiveCN109250914ASimple methodLow equipment requirementsCovering/liningsClaywaresNephelineSolvent

The invention discloses a glaze for achieving a silk glazed surface effect on a tile surface, a preparation method and the tile. The glaze is prepared from the following raw material components by weight: mineral material, limestone, 1-2 parts of dolomite, wollastonite, barium carbonate, calcined talcum powder, feldspar, nepheline, magnesium oxide, barium oxide, aluminum oxide, silicon dioxide anda solvent. The preparation method of the glaze comprises the following steps: adding the raw materials into a mixer according to the number of parts, adding water with the mass of 0.3 to 0.6 time ofthe total mass of the raw materials, mixing and grinding, until the fineness of glaze slip is 600 to 900 meshes, thus obtaining the glaze. The glaze prepared by the method has a soft, fine and smoothhand feeling and has good wear resistance, and the tile surface can have the silk glazed surface effect after the glaze is applied to the tile.

Owner:GUANGDONG SANSHUI TANDH GLAZE CO LTD

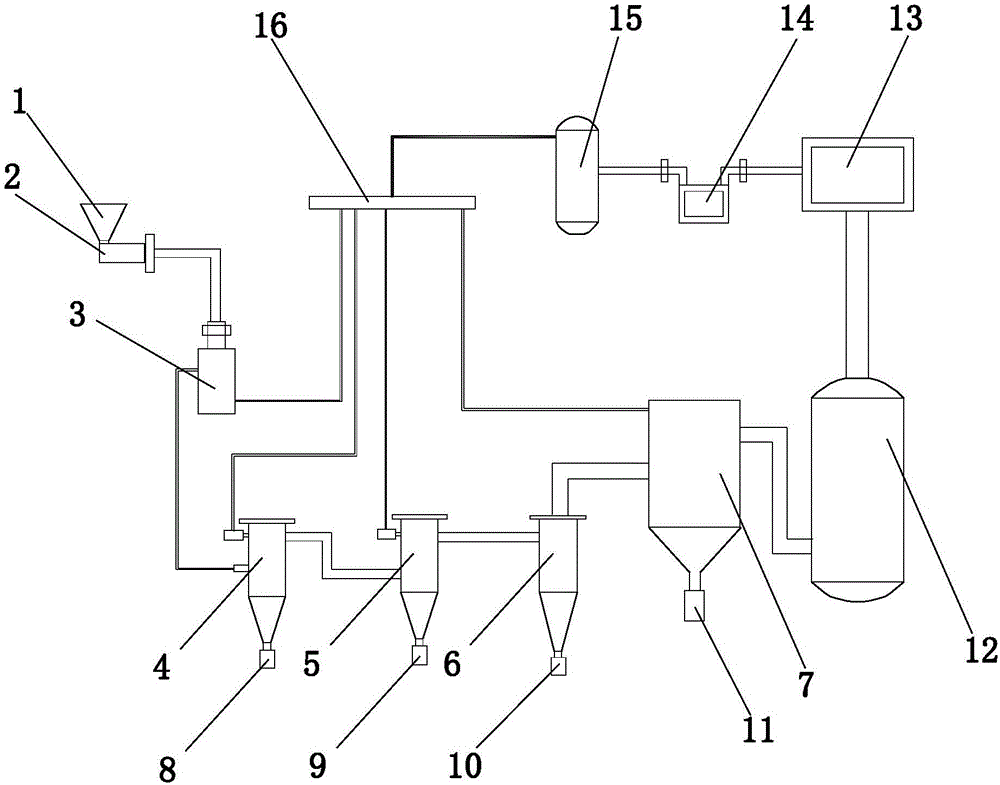

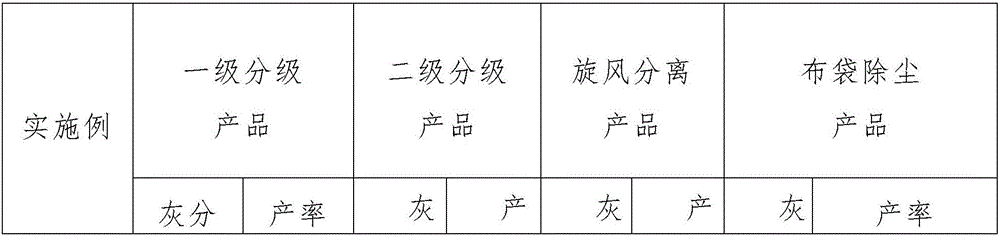

Coking coal quality improving device and quality improving method

The invention provides a coking coal quality improving device. The coking coal quality improving device comprises a quality improving mechanism and a wind power mechanism; the quality improving mechanism comprises a spiral feeding machine, a jet mill, a primary grading machine, a secondary grading machine, a cyclone separator and a bag-type dust collector; the wind power mechanism comprises a balance tank, an air compressor, a refrigeration dryer, a gas storage tank and a distribution valve; the distribution valve is connected with each of the jet mill, the primary grading machine, the secondary grading machine and the bag-type dust collector; the bag-type dust collector is connected with the balance tank. The invention also provides a method for improving the quality of coking coal by utilizing the device. The coking coal quality improving device is scientific and reasonable in design; the problems of deficiencies of sorting by a wet method and high lower limit of the particle size of a conventional dry method sorting technology can be effectively solved; finally, the quality of the coking coal is improved and graded; the coking coal quality improving device is wide in application field, and is suitable for popularization and use.

Owner:XIAN UNIV OF SCI & TECH

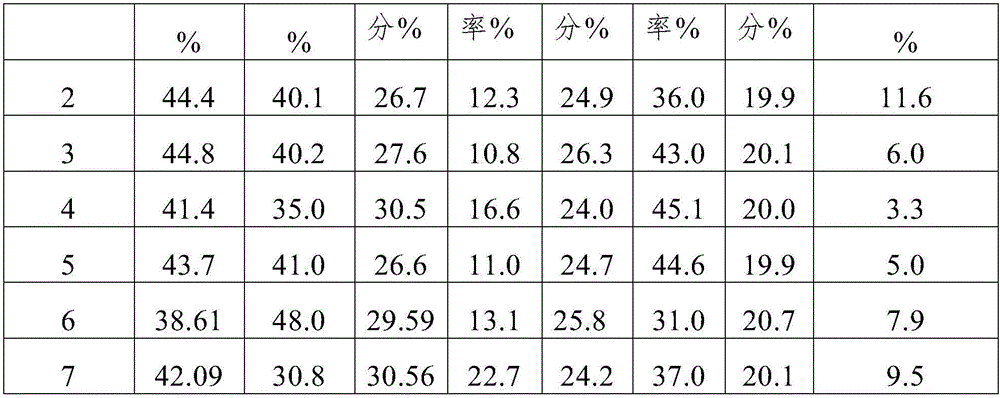

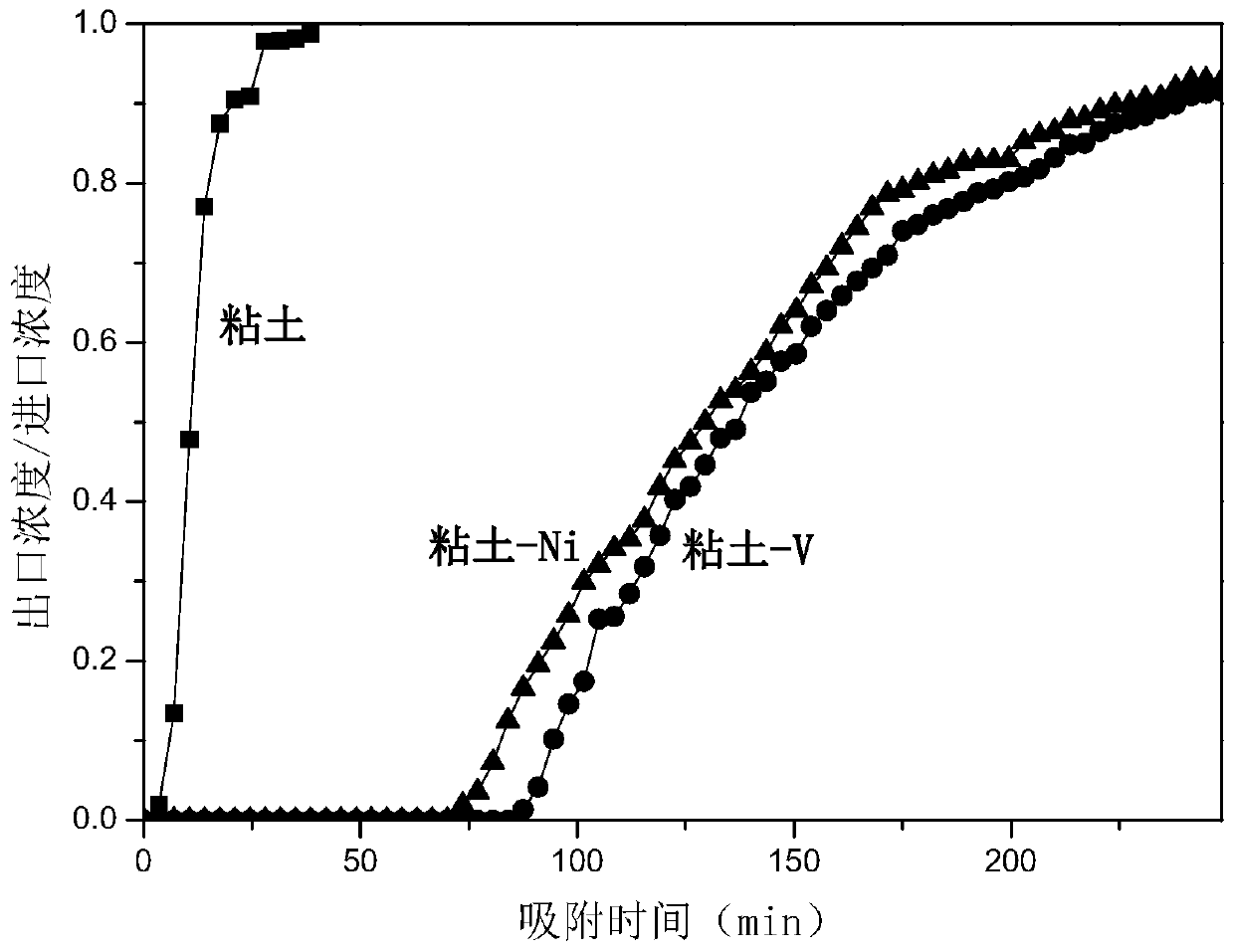

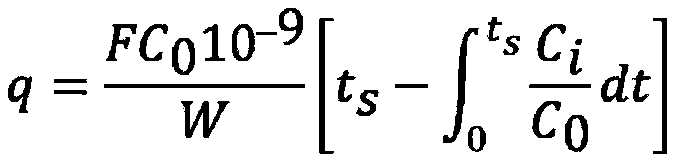

A kind of clay-based composite adsorption material for adsorbing styrene waste gas and its preparation method

ActiveCN107185482BImprove adsorption capacityReduce manufacturing costGas treatmentOther chemical processesActive agentNitrate salts

The invention discloses a preparation method of a novel clay-based composite adsorption material used for adsorption of styrene exhaust gas. The preparation method comprises following steps: 1, clay is added into an acidic solution, and stirring is carried out at room temperature so as to obtain a solution A; 2, a surfactant is added into the solution A, and stirring is carried out at room temperature so as to obtain a solution B; 3, a silicon source and an aluminium source are added into the solution B; 4, a product obtained via step 3 is filtered, and washed until pH value of washing solution is increased to 7, and is subjected to drying and smashing into particles; and 5, a transition metal nitrate is dissolved in deionized water so as to obtain a salt solution, the salt solution is added in the particles drop by drop, and stirring, drying, and roasting are carried out. The novel clay-based composite adsorption material is nontoxic, is friendly to the environment, is low in production cost, and possesses excellent adsorption capacity on styrene; no corrosion is caused; the preparation method is simple; and operation and production are convenient.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

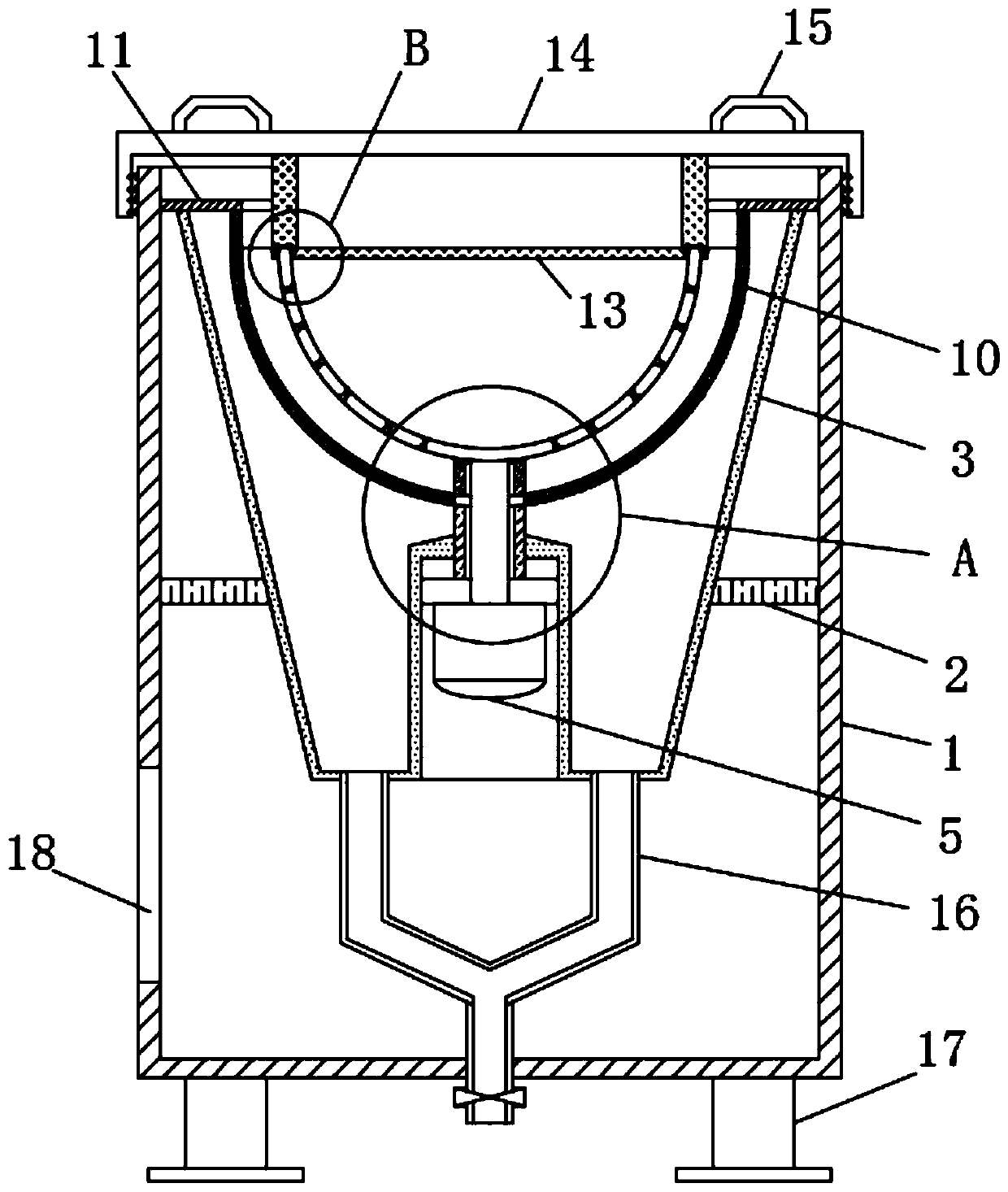

High-speed centrifuge for manufacturing water-based paint and operation method

The invention discloses a high-speed centrifuge for manufacturing a water-based paint. The high-speed centrifuge comprises a high-speed centrifuge body, wherein a reinforcing plate is arranged on theinner wall of the high-speed centrifuge body, a material barrel is arranged on an inner ring surface of the reinforcing plate, a mounting plate is arranged on the surface of the material barrel, a driving motor is arranged on the bottom surface of the mounting plate, a driving shaft of the driving motor is connected with a centrifugal cylinder, and a first enclosure pipe is arranged on the bottomsurface of the centrifugal cylinder. The invention further discloses a high-speed centrifuge for manufacturing the water-based paint and an operation method, and comprises the following steps of feeding, carrying out centrifugal treatment, discharging the materials, and removing particulate matters. The high-speed centrifuge for manufacturing the water-based paint and the operation method has thebeneficial effects that a filter screen cover is additionally arranged between the centrifugal cylinder and the material cylinder by the high-speed centrifuge for manufacturing the water-based paint,after the centrifuged water-based paint impacts the filter screen cover, the water-based paint is dispersed and falls into the material barrel, and the small particles which are not impacted and crushed are isolated between the centrifugal cylinder and the filter screen cover, so that the quality of the finished product of the water-based paint is improved.

Owner:南昌汇达知识产权有限公司

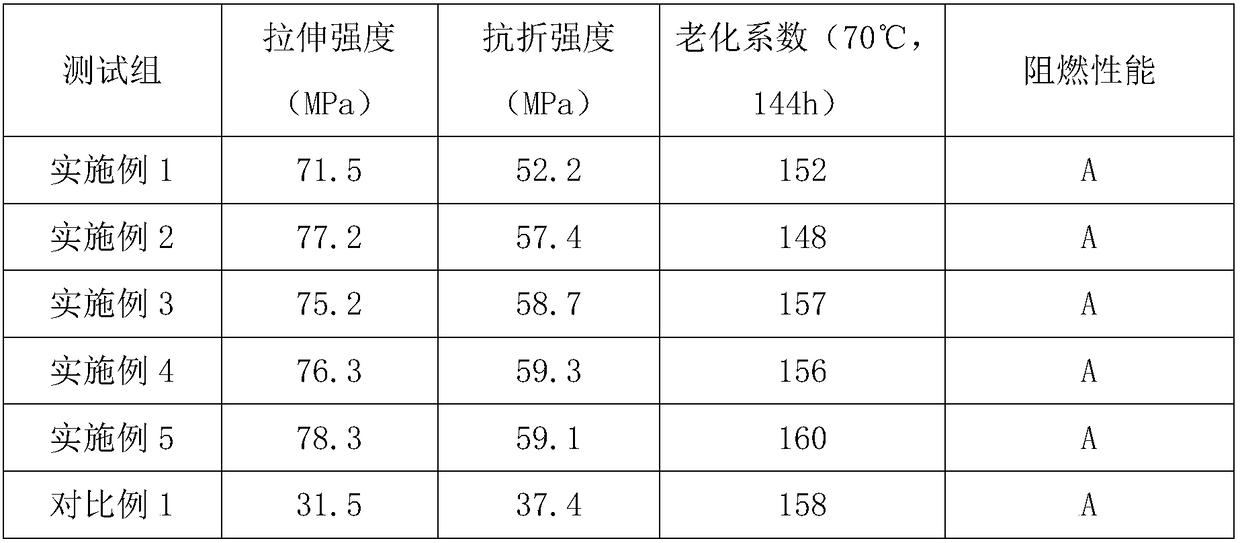

Flame-retarding and environment-friendly cable material for network cabling and preparation method thereof

InactiveCN108359193AHigh flame retardant coefficientImprove environmental performancePlastic/resin/waxes insulatorsAntioxidantAluminum silicate

The invention discloses a flame-retarding and environment-friendly cable material for network cabling and a preparation method thereof and relates to the technical field of cable materials. The flame-retarding and environment-friendly cable material is prepared from the following raw materials in parts by weight: 35 to 48 parts of PVC (Polyvinyl Chloride) resin, 8 to 15 parts of nano silicon carbide, 5 to 10 parts of dinonyl phthalate, 5 to 12 parts of aluminum silicate, 10 to 18 parts of glass fibers, 5 to 10 parts of nano zinc oxide, 4 to 8 parts of nano antimony trioxide, 5 to 10 parts of modified graphene, 4 to 9 parts of calcium carbonate, 3 to 5 parts of flame retardant, 2.5 to 4.5 parts of curing agent, 3.5 to 6 parts of antioxidant, 3.5 to 6 parts of stabilizing agent and 3 to 6 parts of silane coupling agent. The cable material provided by the invention has a high flame-retarding coefficient and low smoke and no toxin in a combustion process; the flame-retarding and environment-friendly cable material has the advantages of high environment-friendly performance, stable chemical properties, high anti-ageing performance, high compression resistance and bending resistance, long service life, high practicability, simple preparation method and easiness for operation and production.

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

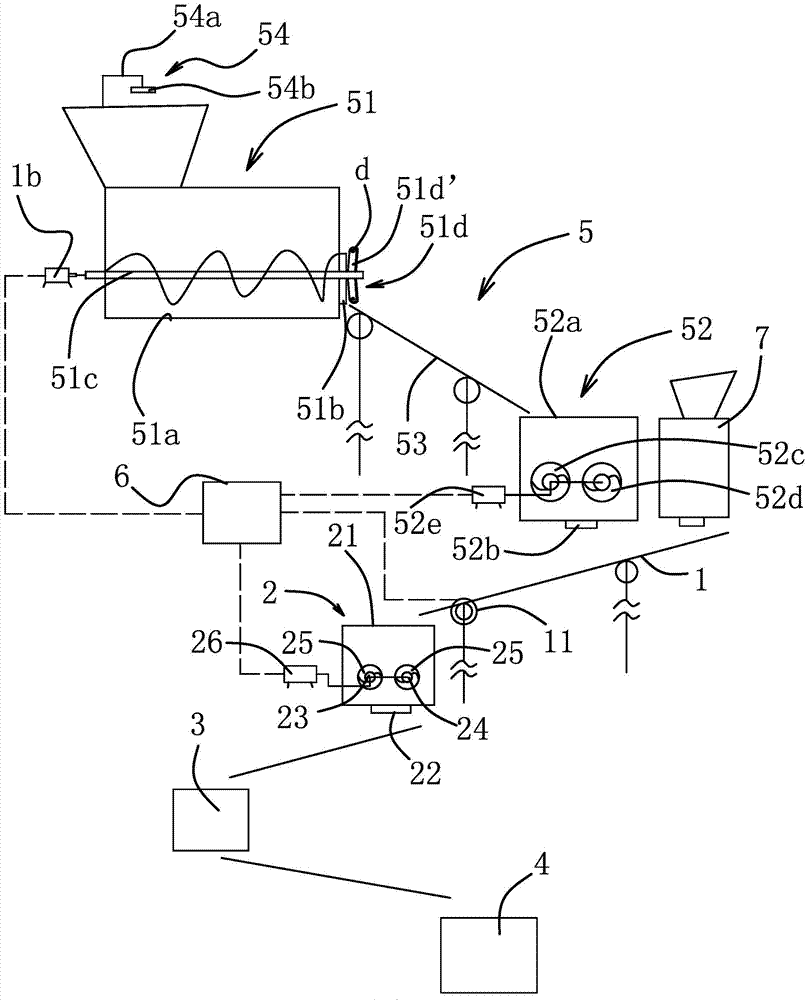

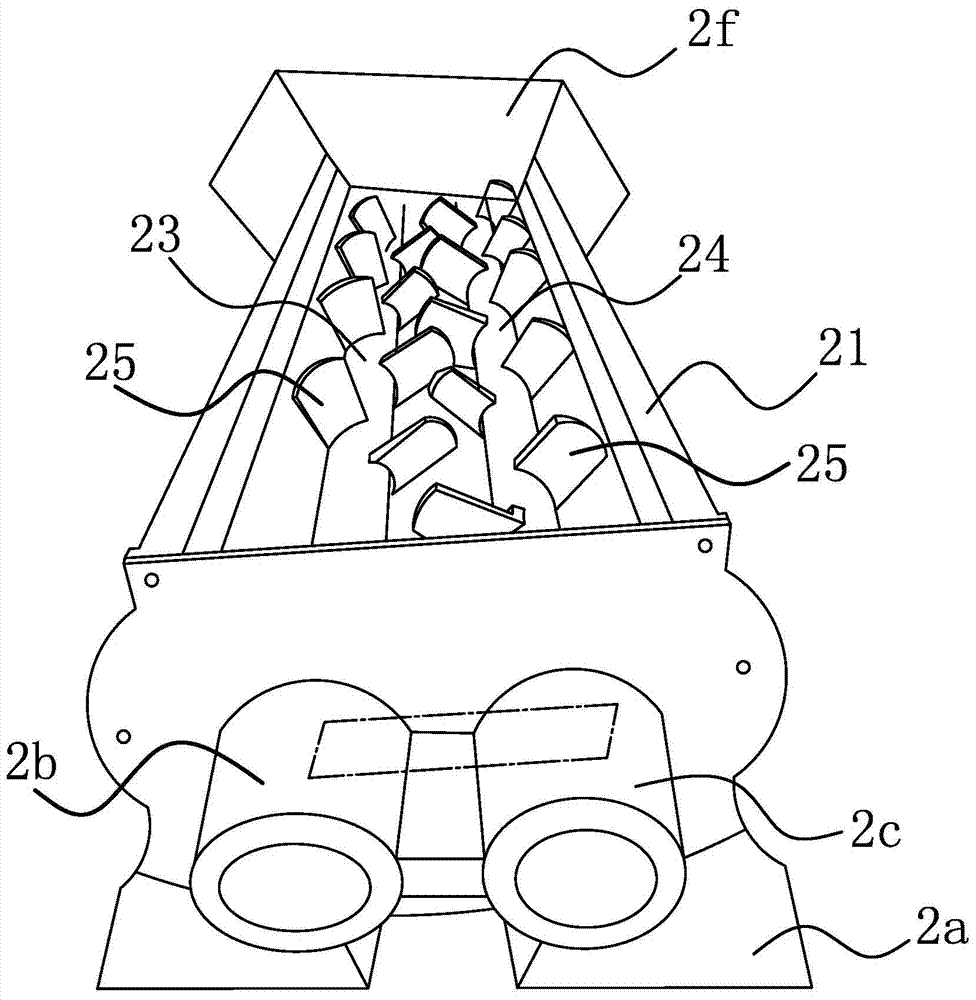

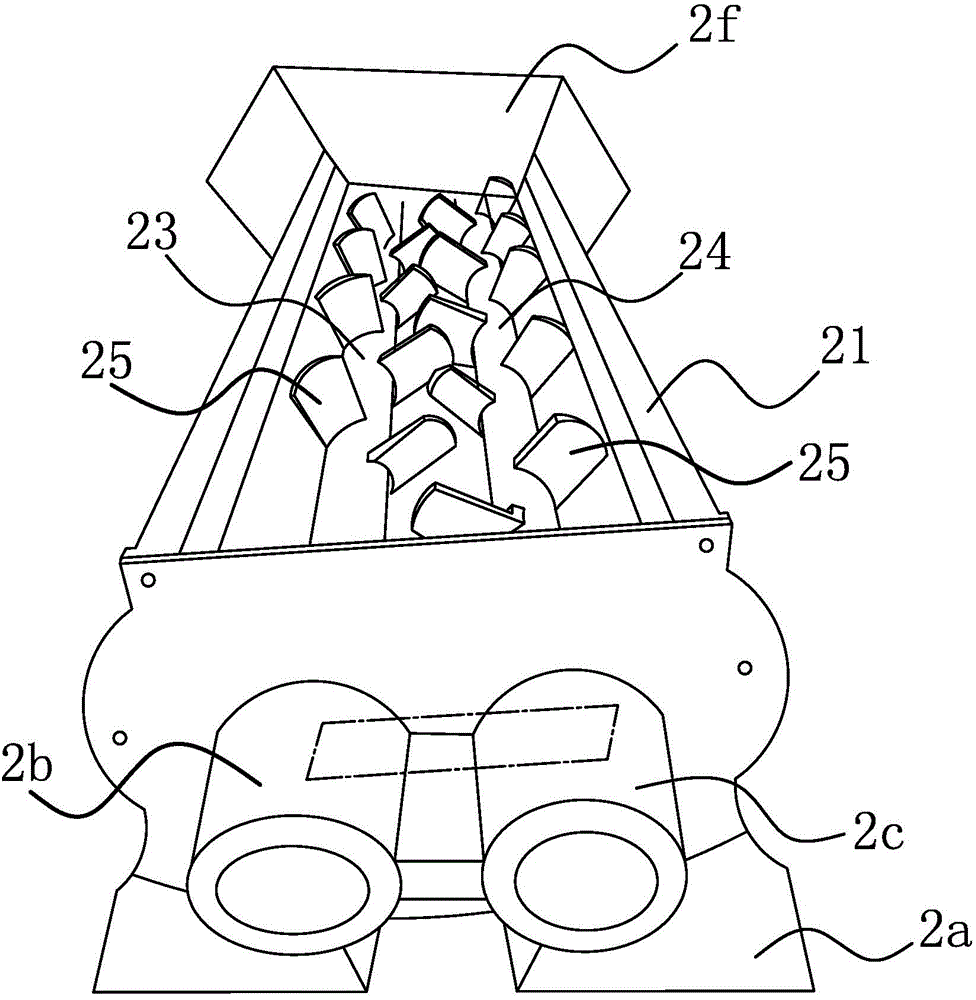

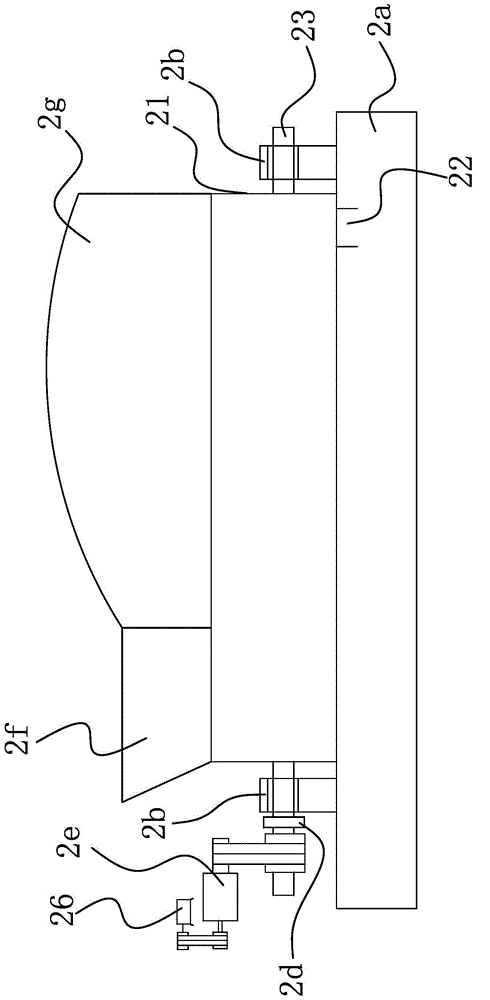

Production system and production process for producing bricks by utilizing paper pulp sludge

InactiveCN103771898AImprove structural strengthReasonable designCeramicwareSludgePulp and paper industry

The invention belongs to the technical field of construction materials, in particular relates to a production system and a production process for producing bricks by utilizing paper pulp sludge, and aims to solve the technical problems of unreasonable design, complicated production process and the like in the prior art. The system sequentially comprises a brick making material conveying device used for conveying a brick making material, an agitation device used for agitating the brick making material, a molding device used for processing the brick making material into an adobe and a brick kiln used for firing the adobe into a brick finished product, as well as a paper pulp sludge adding mechanism used for adding paper pulp sludge into the brick making material, wherein the blanking end of the paper pulp sludge adding mechanism is positioned above the brick making material conveying device. The production process comprises the following steps: A, preparing raw materials; B, fermenting; C, molding an adobe; and D, firing a brick. The production system and the production process have the advantages of more reasonable design, simpler structure and simple process, and is easy to operate and produce.

Owner:黄 建华

Preparation method of brown sugar

An embodiment of the invention discloses a preparation method of brown sugar. The preparation method of the brown sugar comprises the following steps of carrying out squeezing, namely thoroughly washing sugarcanes, cutting the washed sugarcanes into sections of which the length is 10-15 centimeters, and pulping the sugarcane sections in a juicer so as to obtain sugarcane juice; carrying out screen filtering, namely filtrating the pulped sugarcane juice for three times, wherein a screen mesh of which the diameter is 2-5 centimeters is utilized in the first filtration, a screen mesh of which the diameter is 1-1.5 centimeters is utilized in the second filtration, and a gauze is utilized in the third filtration; carrying out evaporation, namely adopting four-effect or five-effect evaporation so as to increase concentration of syrup, and thus, sugar cooking time is beneficially reduced; cooking sugar, namely heating and stirring the purified sugarcane juice until syrup is formed and completely changed into brown sugar; and then, carrying out granulation, namely cooling the brown sugar, crushing the cooled brown sugar in a granulating machine so as to obtain granulated brown sugar.

Owner:雷燕梅

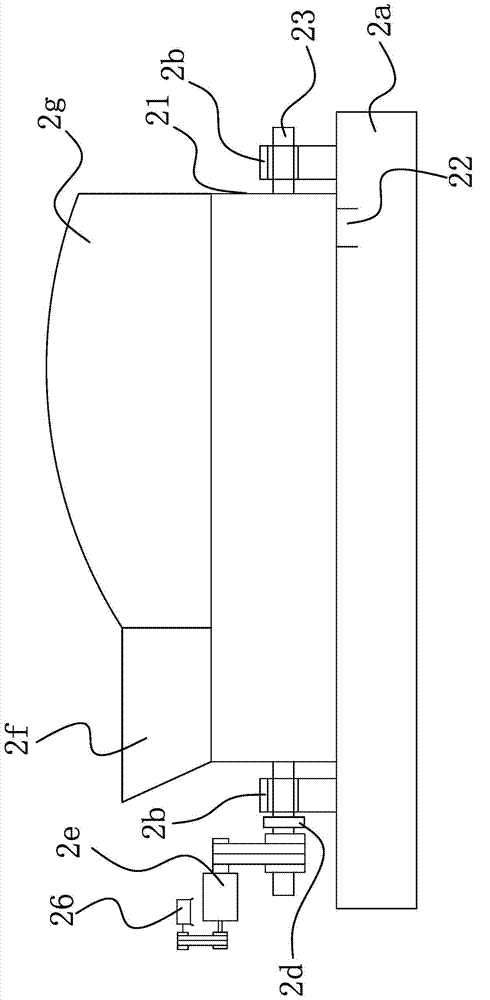

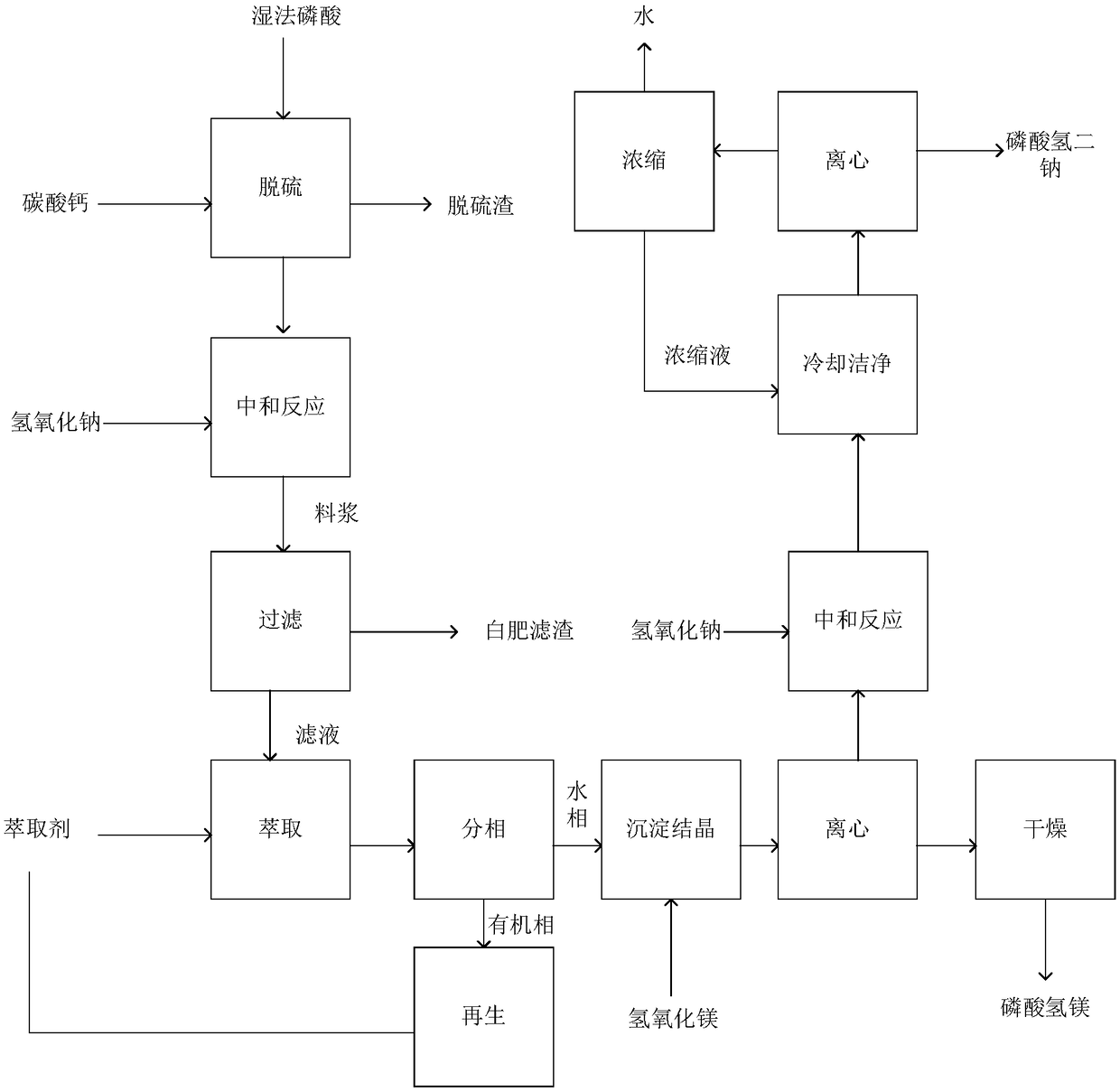

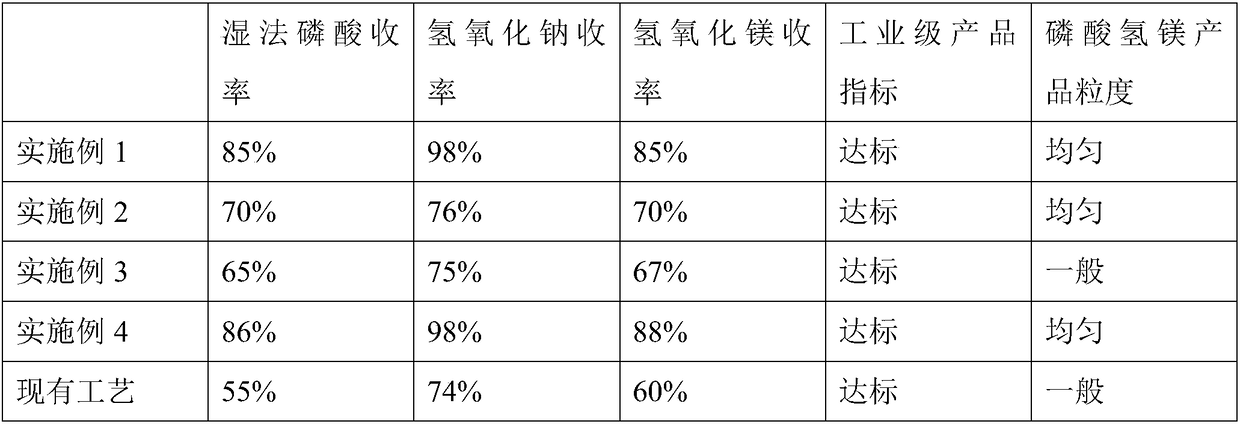

Technology for adopting wet process phosphoric acid as raw material to prepare magnesium hydrogen phosphate

InactiveCN108328592ASimple preparation processEasy to operate and produceOther chemical processesWater contaminantsCalcium bicarbonateSlag

The invention discloses a technology for adopting wet process phosphoric acid as a raw material to prepare magnesium hydrogen phosphate. Calcium carbonate is added into wet process phosphoric acid tobe subjected to desulfuration in a desulfuration phosphoric acid device, stirring is conducted for 4 hours at the temperature of 60 DEG C, and the revolution number of a stirrer is 300 r / min; sodium hydroxide is added into desulfuration phosphoric acid, a reaction is carried out for 4 hours under the conditions that the PH value is 4.5 and the reaction temperature is 60-70 DEG C, phosphate or ironand aluminum is precipitated so that main impurities can be removed, the slurry is filtered, and calcium bicarbonate filter slag is obtained; 35mL of a P507 extraction agent is added into the filterliquid, extraction is conducted for 10 minutes at the room temperature, phase splitting is conducted, a water phase enters a next reaction device, an organic phase is regenerated and recycled throughthe P507 extraction agent to be used cyclically; magnesium hydrate is added into the water phase to adjust the PH value to be 6-6.5, and a precipitation crystal is obtained; and the precipitation crystal is subjected to centrifugal separation, the crystal obtained through separation is dried, and magnesium hydrogen phosphate is obtained. The technology effectively reduces the production cost, andimproves the production efficiency.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

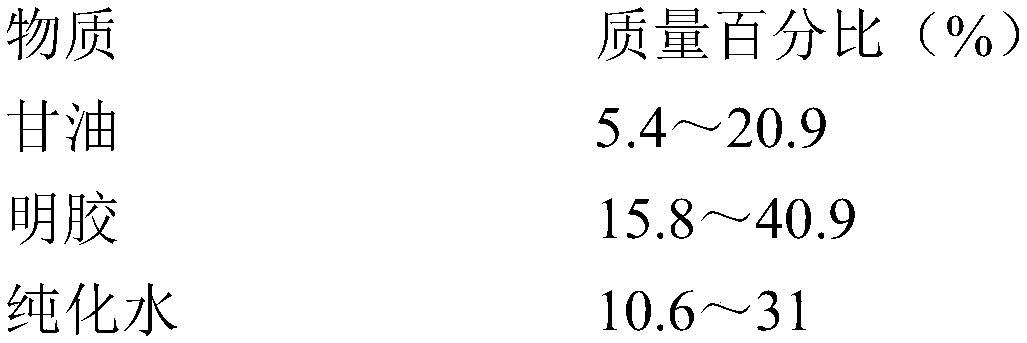

Ozone active oil soft capsule and preparation method and application thereof

InactiveCN108815132AEasily damagedEasy to useAntibacterial agentsInorganic active ingredientsIrritationOral ulcers

The invention provides an ozone active oil soft capsule and a preparation method and application thereof. The content of the ozone active oil soft capsule is 40% to 61% by mass of ozone oil. The softcapsule can realize the oral administration of ozone, greatly alleviates the suffering of patients with alteration of intestinal flora, avoids the irritating effect of oral ozone on respiratory tracts, can be used for regulating the gastrointestinal flora, promoting digestion, relaxing bowels, has auxiliary protective functions for gastric mucosal damage, gum swelling, oral ulcers, skin inflammation, and the like, and is exact in curative effect. The invention also provides the preparation method of the ozone active oil soft capsule, the preparation method is simple and easy in production process, can be applied to industrial production, can stably and stably produce qualified products, and has broad application prospects.

Owner:广东祈福医院有限公司

Method for preparing pumpkin sausage egg cake

InactiveCN102986781ANice appearanceDeliciousDough treatmentBakery productsBiotechnologyMonosodium glutamate

The invention discloses a method for preparing a pumpkin sausage egg cake belonging to the field of food processing. The method comprises the following steps of juicing a pumpkin, cutting a sausage into sections with the length of 5mm, the width of 5mm and the height of 2mm, mixing egg liquid, wheat flour, edible salt, monosodium glutamate, five spice powder, chopped green onion and water to form egg liquid; and mixing the pumpkin juice, the sausages and the egg liquid, and burning and cooking to form the pumpkin sausage egg cake. The pumpkin sausage egg cake tastes delicious and has high nutrient value. According to the method, fresh pumpkins are selected, the requirement on the sausages is low, and general ham sausages can be used; the sizes and the thicknesses of the cut sausages are the same; the preparing technology is simple; the cost is low; and the pumpkin sausage egg cake is easy to operate and produce.

Owner:王爽

Anti-cracking anti-corrosion cable material and preparation method thereof

InactiveCN108912457AImprove heat resistanceGood weather resistancePlastic/resin/waxes insulatorsMaterials scienceRaw material

The invention discloses an anti-cracking anti-corrosion cable material and a preparation method thereof, and relates to the field of a cable material. The cable material is prepared from the followingraw materials in parts by weight: 50 to 60 parts of high density polyethylene, 18 to 25 parts of ethylene-vinyl acetate copolymers, 3 to 8 parts of maleic anhydride grafted polyethylene, 5 to 10 parts of modified polytetrafluoroethylene particles, 5 to 10 parts of nanometer titanium dioxide, 22 to 27 parts of aluminum hydroxide, 3 to 8 parts of chitin, 1.8 to 4.2 parts of plasticizers and 1.6 to3.5 parts of antioxidizers. The cable material has the advantages that through the cooperated matching effect between the raw materials, good heat resistance, weather resistance and anti-corrosion performance can be realized; the mechanical toughness and the anti-stretching performance are excellent; the durability and the fireproof performance are high; the use safety is high; the preparation method is simple; the operation and the production are easy.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

Production method of carrot and beef cake

The invention discloses a production method of carrot and beef cake. The method comprises the following step of (a) beef slice preparation: chopping beef into meat emulsion; after the uniform stirring, adding table salt, crushed rock sugar, chicken essence, water, cooking wine and buckwheat; performing uniform stirring; then, putting the materials into a mold for shaping; freezing the materials until the center temperature is -3 DEG C; cutting the materials into a flaky material with the thickness being 0.65cm by a slicing machine; then, feeding the materials into a steaming cabinet to be heated at the heating temperature of 95 DEG C, wherein the center temperature reaches 75 DEG C; maintaining the condition for 4 to 5 minutes; cooling the materials to the room temperature; dipping oat flour onto the two sides of the beef slices. The requiring conditions on the raw material meat are low; the production can be performed on minced meat; meanwhile, the cut beef slices have the regular shape and the uniform size. Compared with the prior art, the production method has the advantages that the thickness of the beef slices obviously becomes thick; the production process is reasonable; thecost is low; the operability is high; the large-scale production can be easily realized.

Owner:邹兰英

Decorative art fruit making method

InactiveCN1840365ADoes not affect developmentEasy to operate and produceSpecial ornamental structuresAlcoholEngineering

The invention discloses a craft ornamental fruit preparing method, which comprises the following steps: using transparent bottle of 2-3cm upper caliber to fill the dropped flower of 0.1-1cm diameter in bottle to grow; fixing the transparent bottle; covering the dark bag over the bottle body until the fruit ripe; shearing the fruit handle part; tying-up the fruit handle root on inner seal ring; hanging the fruit in glass bottle; clearing the fruit with clear water; immersing the 5%-30% blue copperas liquor for 1-9 days; poaching to clean; immersing in the miscible liquids with 5-60ml 1-30% sulfurous acid and 10-60ml 95-99% alcohol. The invention simplifies the operation, which reduces the cost.

Owner:程相喜

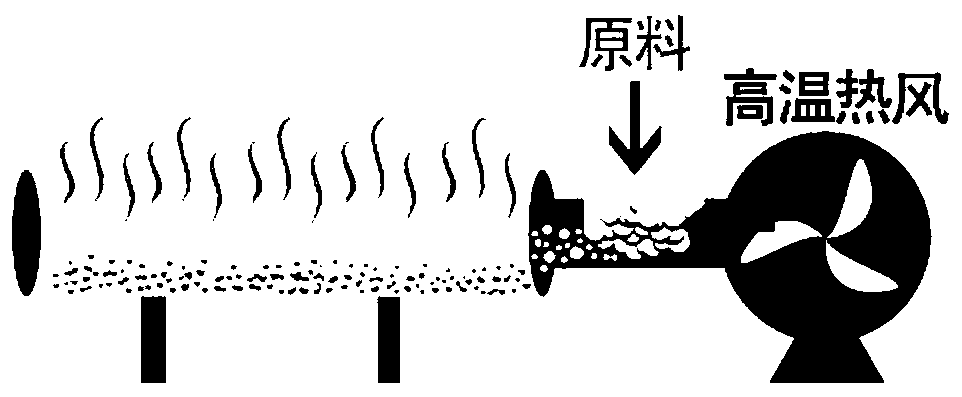

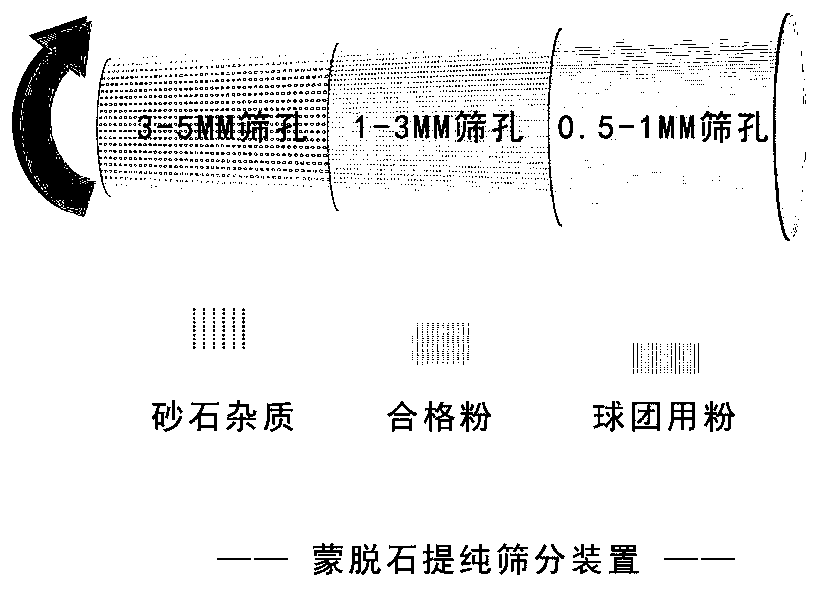

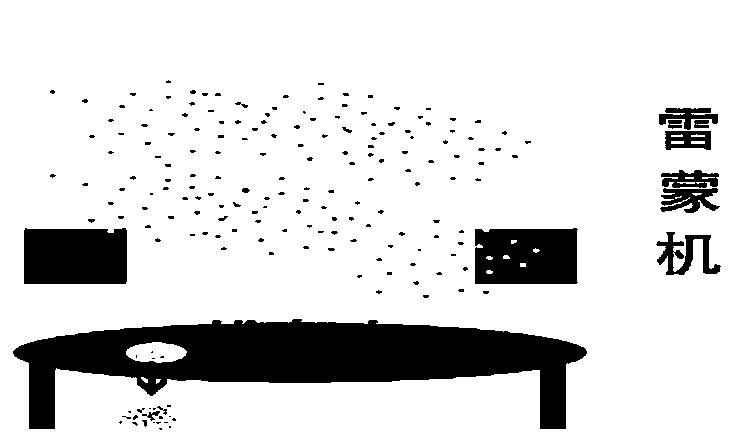

Montmorillonite dry purification process

ActiveCN111484026ADisintegrates quicklyHigh puritySilicon compoundsGrain treatmentsPhysical chemistryMontmorillonite

The invention discloses a montmorillonite dry purification process. The dry purification process comprises the following steps: putting montmorillonite into a high-temperature airflow condition for disintegration; then heating mixed particles, measuring the particle size distribution of montmorillonite particles and impurity particles, designing a screening device, and screening the mixed particles; then grinding to obtain montmorillonite fine powder; grinding the montmorillonite fine powder by using a grinding roller to separate out impurities in the montmorillonite fine powder, adjusting theairflow pressure by using a Raymond mill to enable the impurities to settle downwards, removing the impurities through impurity removal holes of the Raymond mill, and collecting unsettled fine powderto obtain purified montmorillonite. According to the method, the montmorillonite is purified by adopting the dry purification process, so that the application of water resources and chemical substances is reduced, the method is low in purification cost, high in efficiency, good in continuous performance and easy to operate and produce, the purity of the montmorillonite purified by the method canbe improved by about 20%, and the method has an excellent industrialization prospect.

Owner:内蒙古和正美生物科技有限公司

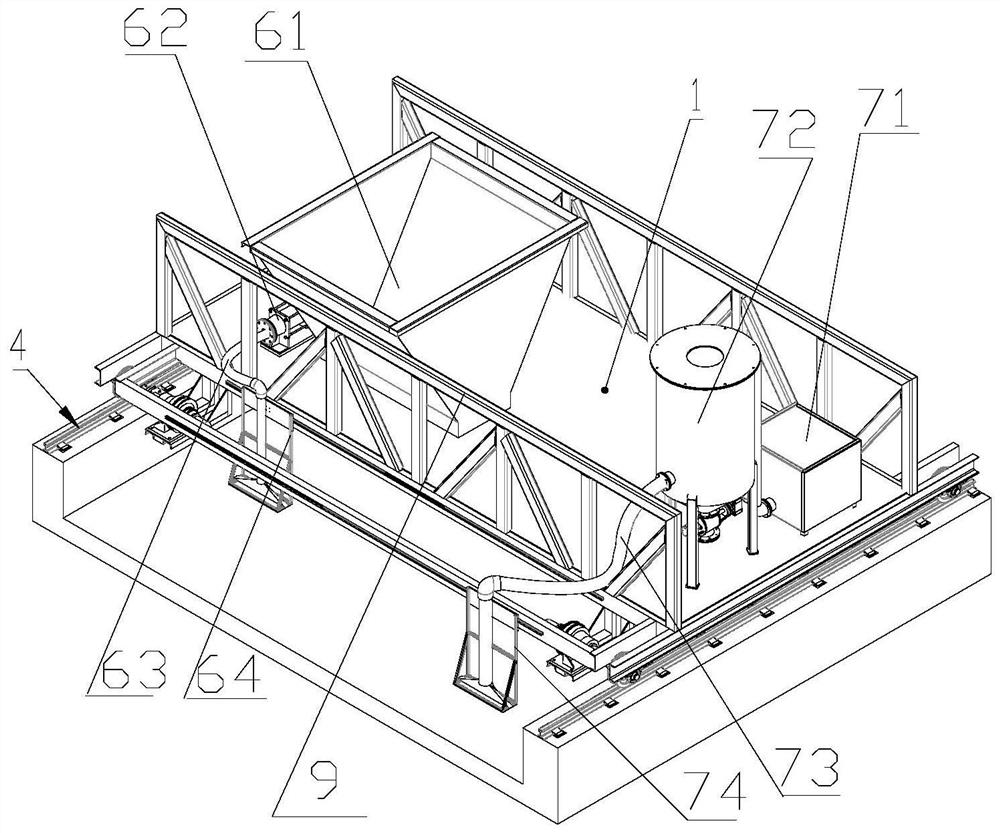

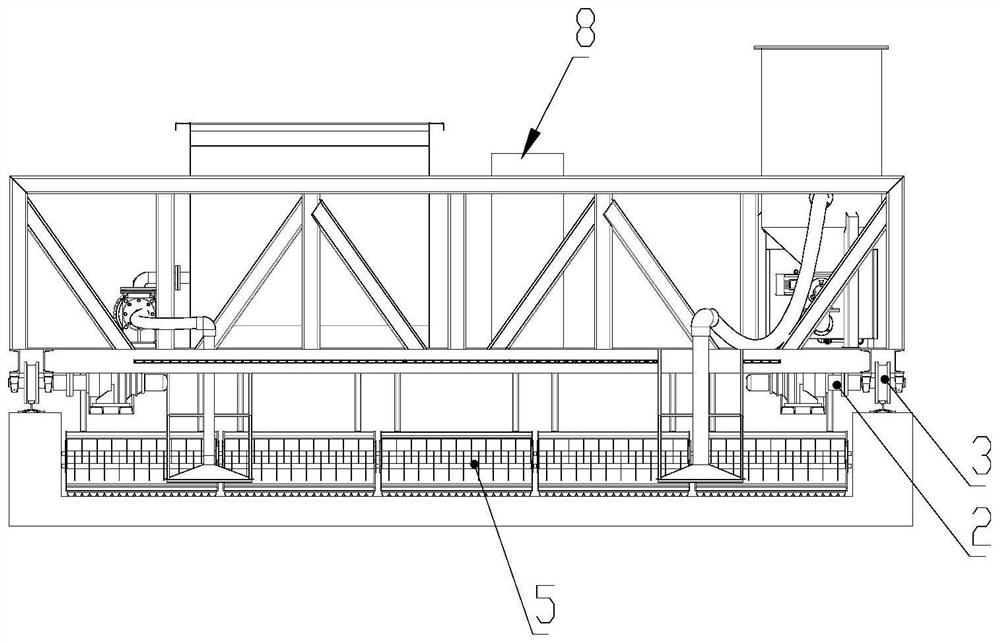

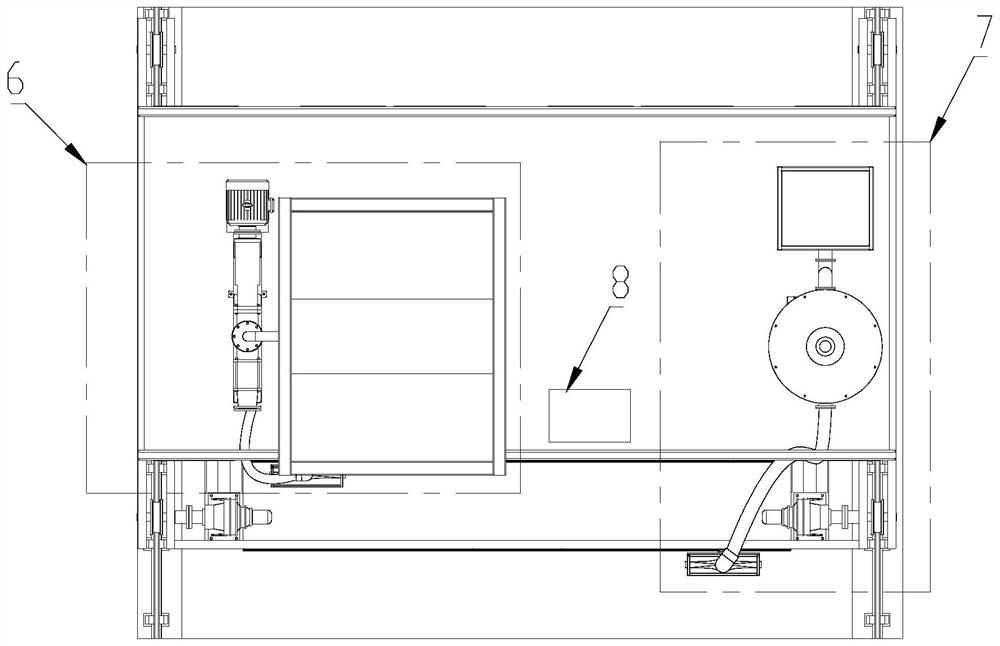

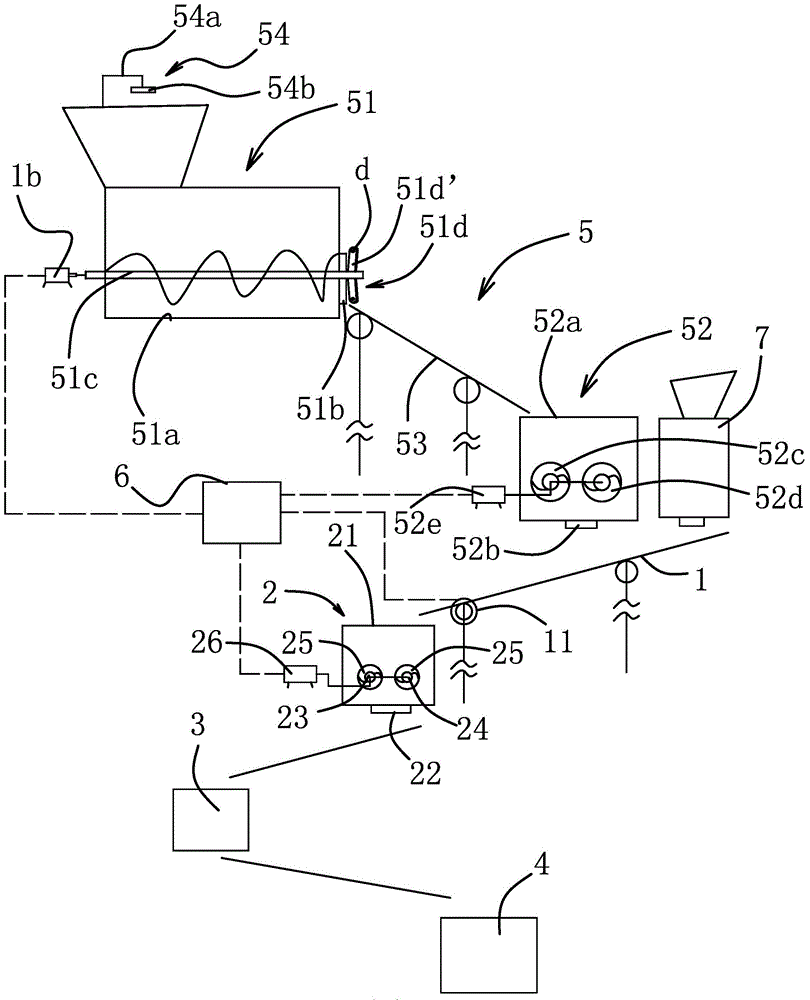

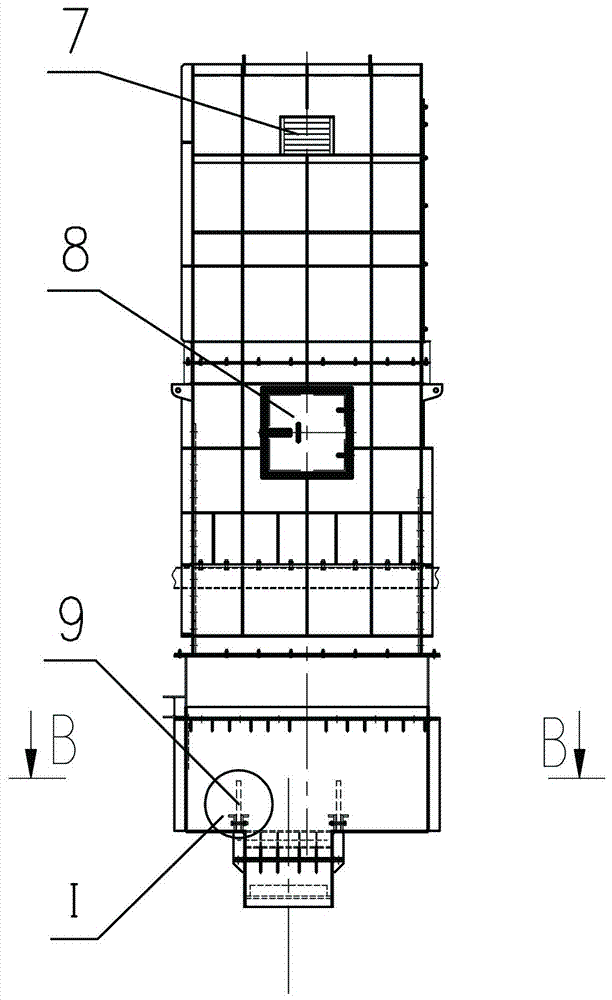

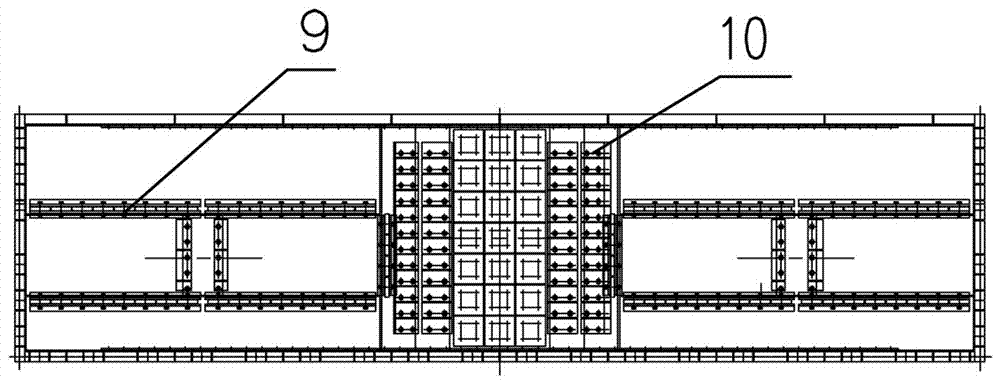

Integrated management device for Hermetia illucens L. breeding

PendingCN111820190AUniform and accurate receivingSuitable for large-scale intensive managementAnimal husbandryAnimal scienceEngineering

The invention discloses an integrated management device for Hermetia illucens L. breeding. The integrated management device includes a bridge-type main beam, a double-drive reducer, a wheel device, atrack device, an automatic oxygen supplying and stirring device, an automatic material distributing device, an automatic material receiving device and a control device. The automatic oxygen supplyingand stirring device, the automatic material distributing device, and the automatic material receiving device are installed on an operating platform of the bridge-type main beam, a material distributing opening and a material receiving opening of the automatic material distributing device and the automatic material receiving device slide on the operating platform to enable material distributing andmaterial receiving to be more even and accurate, and adjusting can be carried out manually. The control device controls the opening and closing of the automatic oxygen supplying and stirring device,the automatic material distributing device and the automatic material receiving device, so that an automatic management device integrated with automatic feeding (positive pressure pumping), automaticmaterial receiving (negative pressure vacuum), automatic material bed stirring and inspection is achieved, the integrated management device is suitable for large-scale intensive management and convenient to operate and product, time and effort are saved, and the work efficiency is improved.

Owner:GUANGDONG HUIZHONG WATER TREATMENT EQUIP CO LTD

Production system and production process for producing bricks from pulp sludge

InactiveCN103771898BImprove structural strengthReasonable designCeramicwareSludgePulp and paper industry

Owner:黄 建华

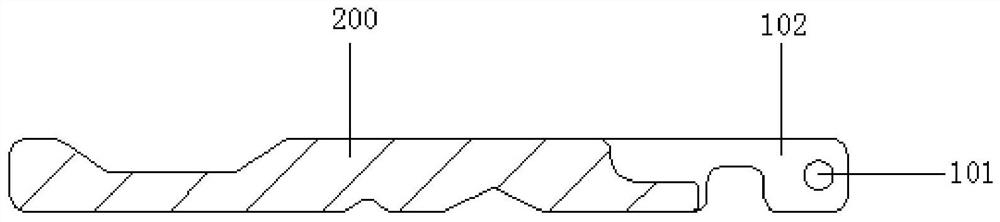

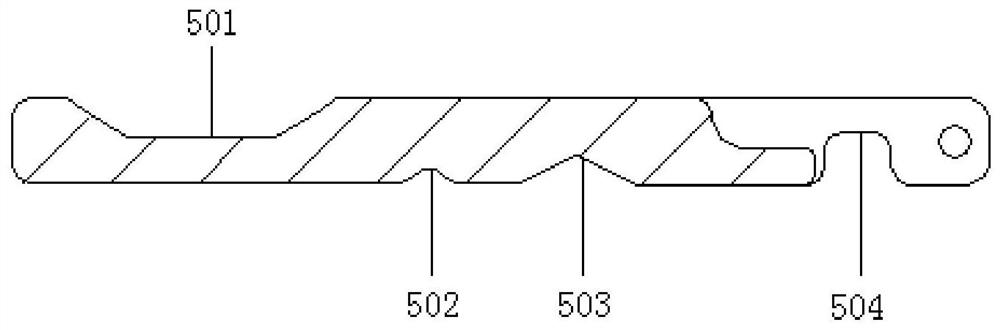

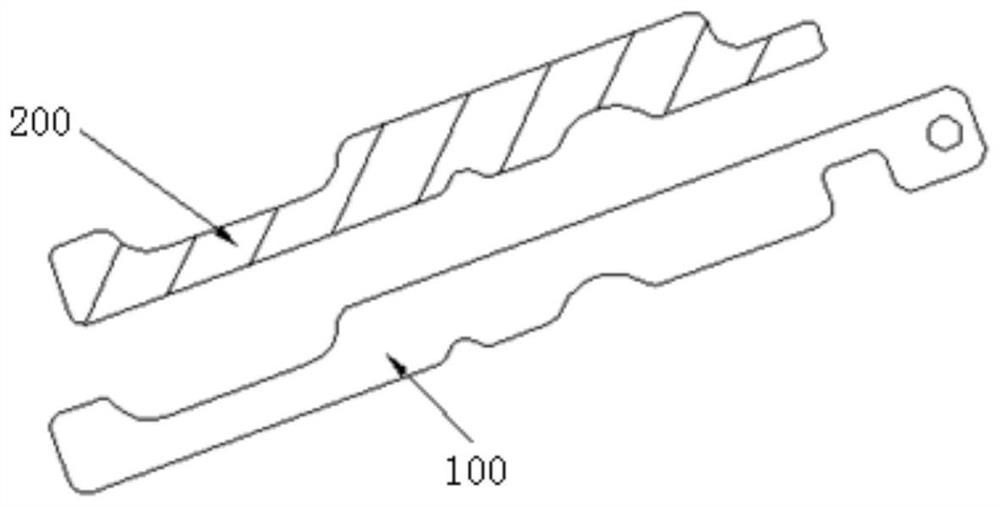

A kind of double-sided adhesive product skip small edge processing method

ActiveCN112571504BEliminate all kinds of risksEasy to operate and produceMetal working apparatusPunchingStructural engineering

Owner:上海昊佰智造精密电子股份有限公司

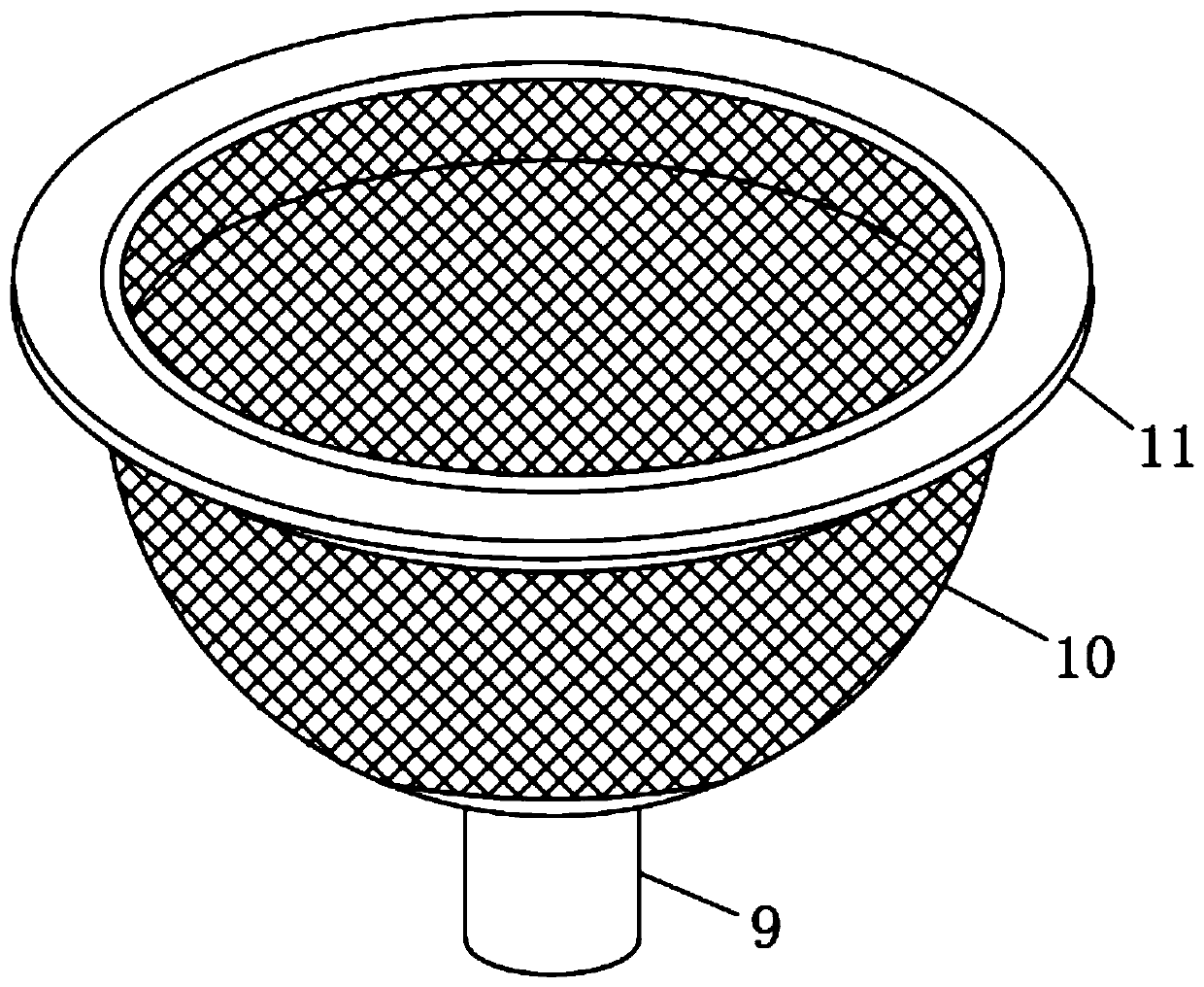

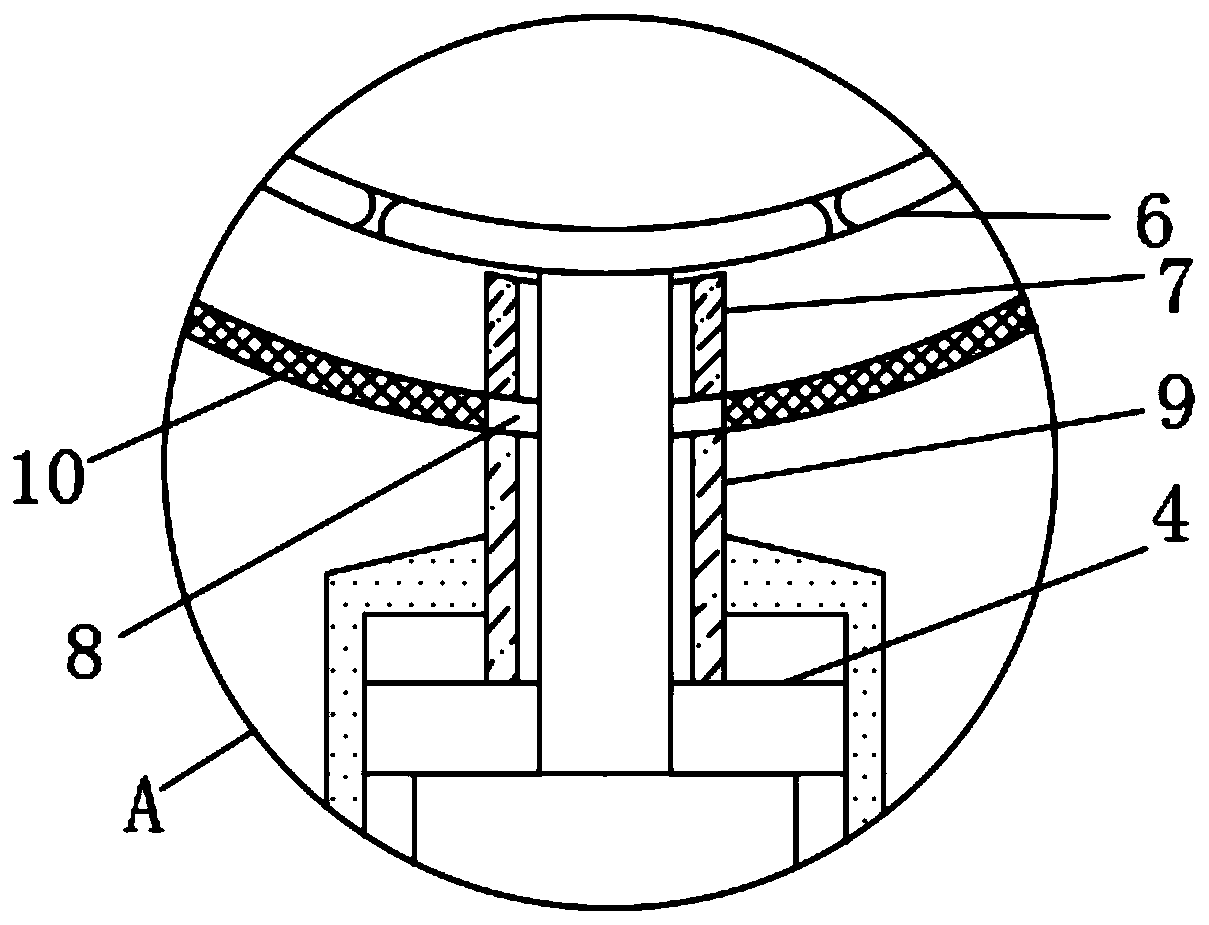

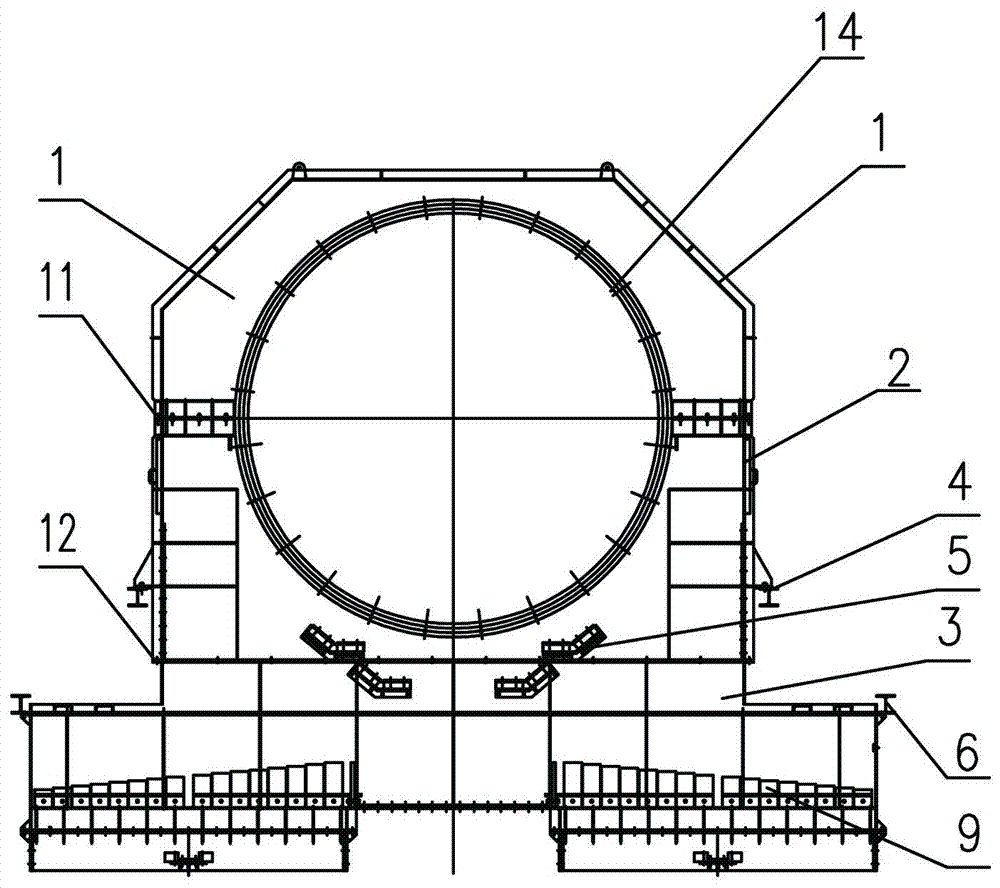

Autogenous mill/semi-autogenous mill discharging flow distribution device

PendingCN107282278AEasy to transportEasy to install and disassembleGrain treatmentsEngineeringStructural engineering

The invention discloses an autogenous mill / semi-autogenous mill discharging flow distribution device. The device comprises an autogenous mill / semi-autogenous mill discharging outlet, and further comprises an upper end cover, a middle aggregate mechanism and a lower flow distribution mechanism. The middle aggregate mechanism comprises an aggregate box and a flow guiding plate. The lower flow distribution mechanism comprises a flow distribution base and flow distribution plate sets arranged on the left and right sides of the bottom of the flow distribution base; the upper end cover, and the middle aggregate mechanism and the lower flow distribution mechanism are supported and suspended on a platform beam of an autogenous mill / semi-autogenous mill through connecting supports outside the two sides of the middle aggregate box and connecting hanging brackets outside the two sides of the flow distribution base. The autogenous mill / semi-autogenous mill discharging flow distribution device has the advantages that by arranging the flow guiding plate and flow distribution plates, uniform discharging of the discharging region is achieved, it is ensured that a vibration screen receives materials uniformly, the screening efficiency and the processing capability are improved, and the production cost is lowered; the flow distribution plates are convenient to transport, assemble, disassemble and adjust, and a lining plate is replaced; by arranging an exhaust window and a viewport, convenience is brought to operation and production of post holders.

Owner:中冶北方(大连)工程技术有限公司

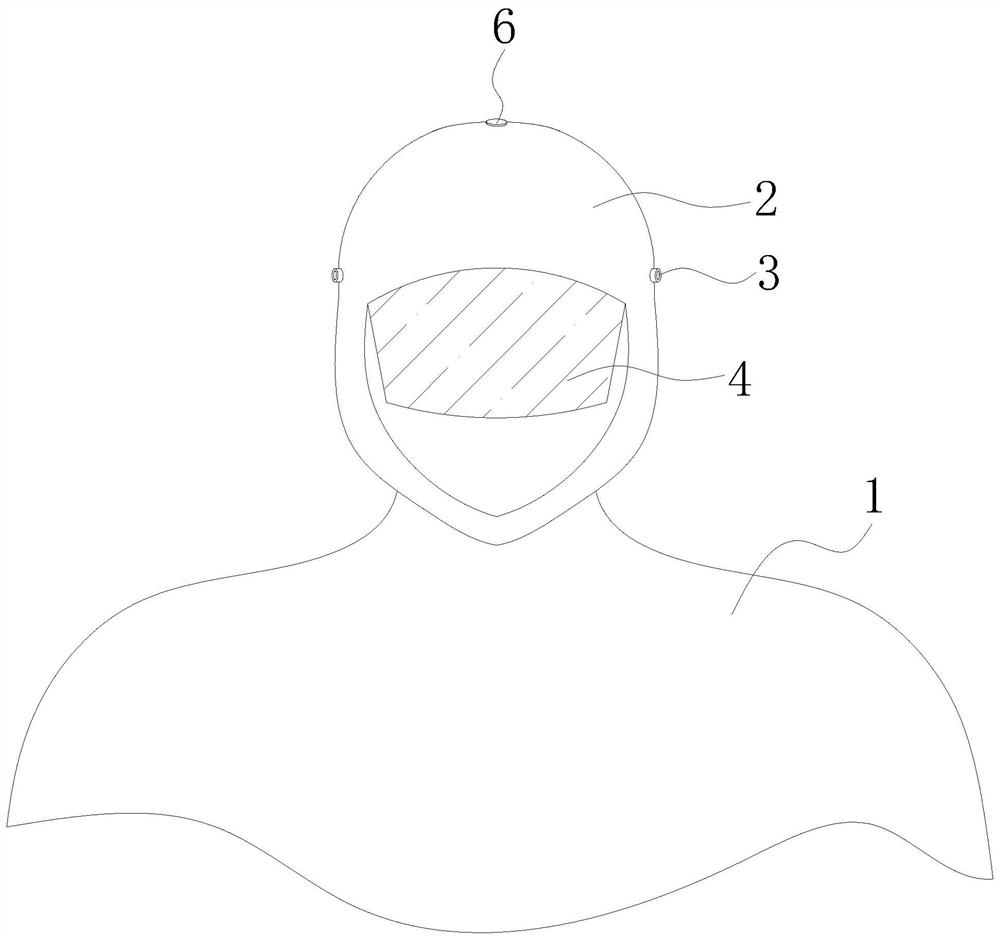

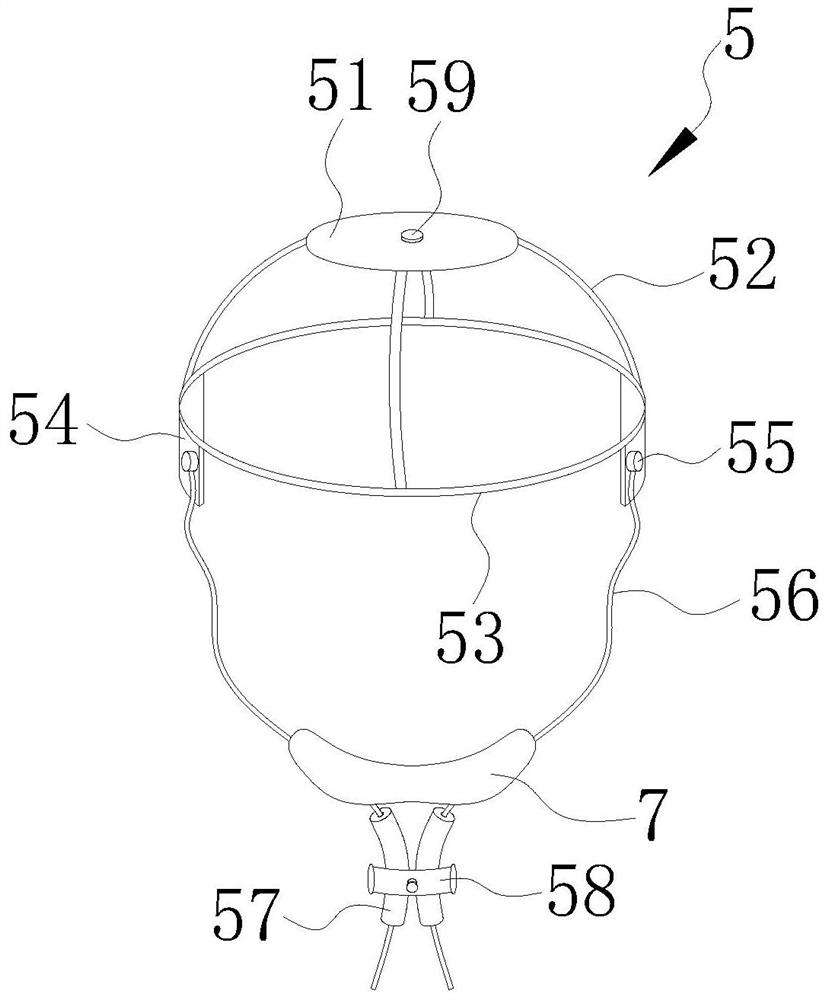

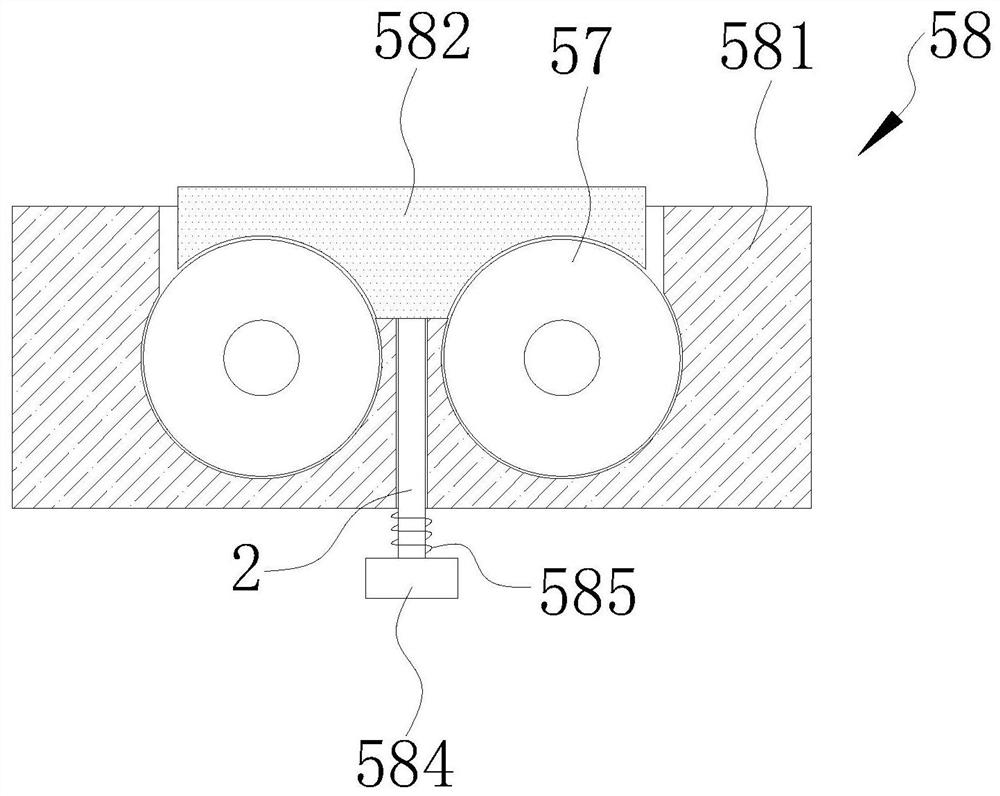

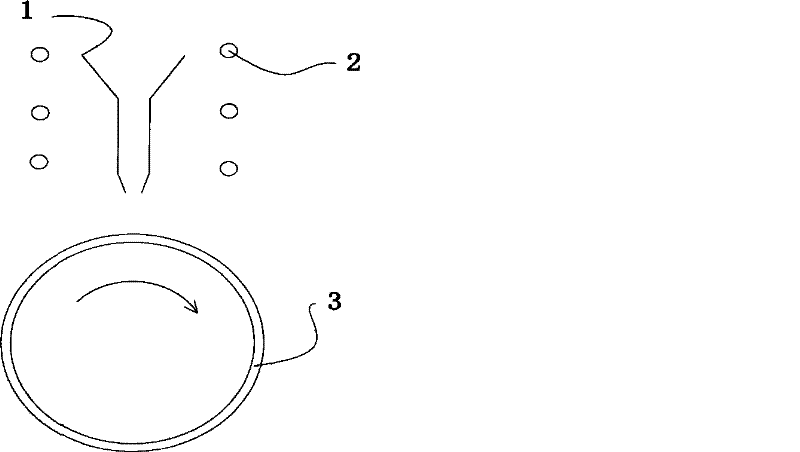

Electric vehicle raincoat capable of fixing head rain cover and assembling method of electric vehicle raincoat

The invention relates to the technical field of raincoats, and discloses an electric vehicle raincoat capable of fixing a head rain cover, the electric vehicle raincoat comprises a raincoat body and the head rain cover sewn on the top of the raincoat body, the ear sides of the two sides of the head rain cover are each provided with a small outer snap fastener penetrating through the inside and the outside, and a rain shielding mask is arranged at a face opening of the head rain cover. A fixed head frame is adhered to the inner top of cloth of the head rain cover, a large outer snap fastener is mounted in the center of the top of the head rain cover, the fixed head frame comprises a top round block and four connecting strips fixed to the periphery of the top round block, a head ring is fixed to the lower ends of the four connecting strips, and fixing pieces are fixed to the bottoms of the two sides of the head ring. A small inner snap fastener buckled on the small outer snap fastener is fixed on the outer side wall of the fixing piece, a tightening rope is fixed on the outer side face of the fixing piece, and a rubber sleeve is arranged outside the lower end of the tightening rope. According to the raincoat, the problems that a head cover part of a traditional raincoat cannot be fixed, sliding often occurs, the sight is blocked, and particularly the situation is more serious in a strong wind and heavy rain environment are solved.

Owner:ANHUI YOOAN RAINGEAR

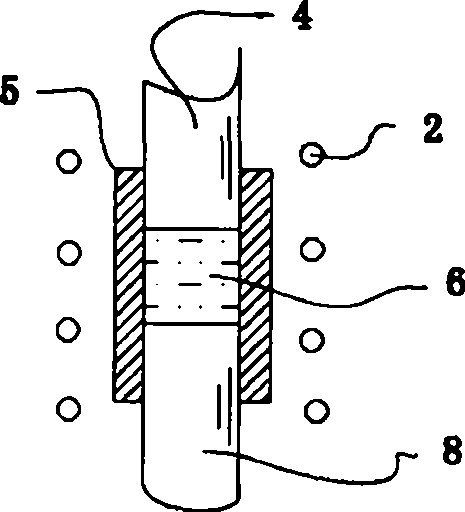

Method for preparing manganese-aluminium hard-magnetic alloy

The invention provides a method for preparing manganese-aluminium hard-magnetic alloy, which is characterized by: (1) heating the raw material alloy comprising transition metal elements, rare earth elements and non-metallic elements to obtain melting alloy; (2) rapidly quenching in a speed of 1*10<5>-1*10<6> DEG C / s to obtain an alloy band; and (3) hot working the alloy powder under the protection of vacuum / inert atmosphere. The method has advantages of low cost increase on raw material compared with the initial prescription, comprehensive utilization of rapid quenching and hot working, greatincrease of magnetic property of the products and easy operation and production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

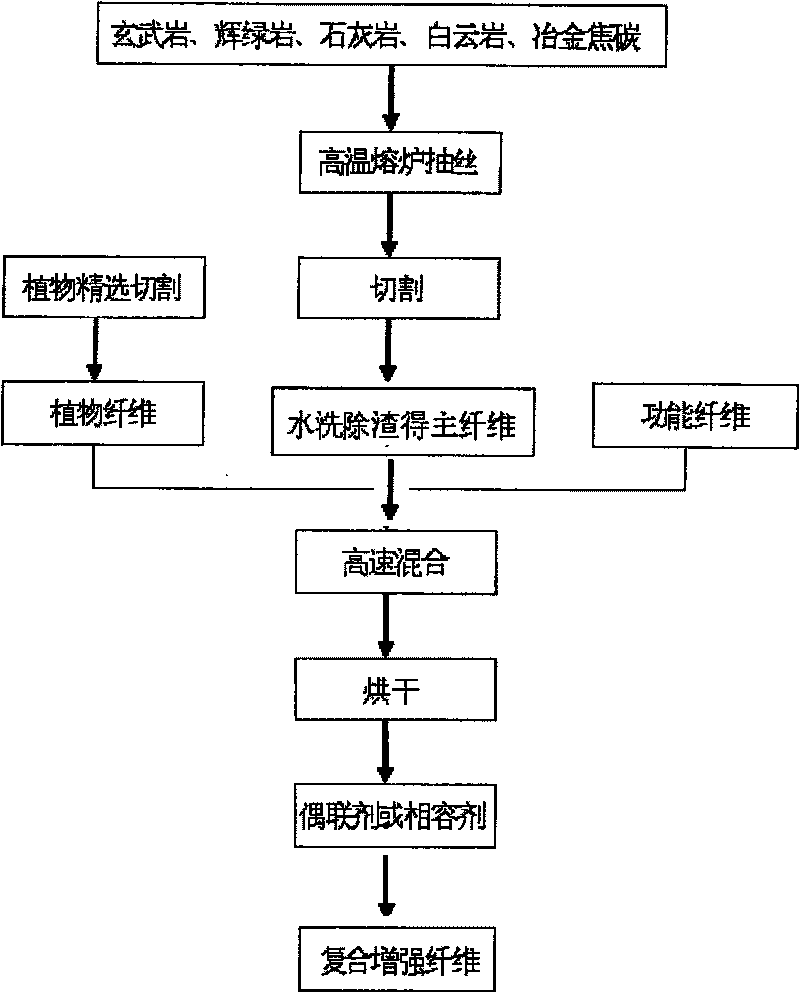

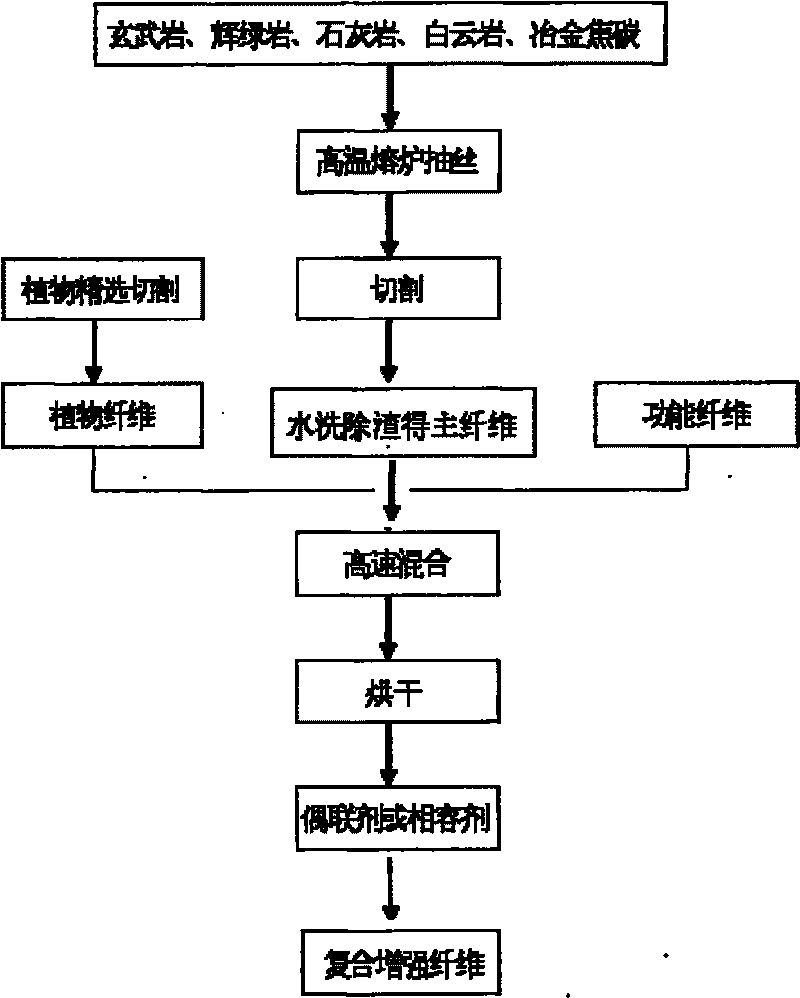

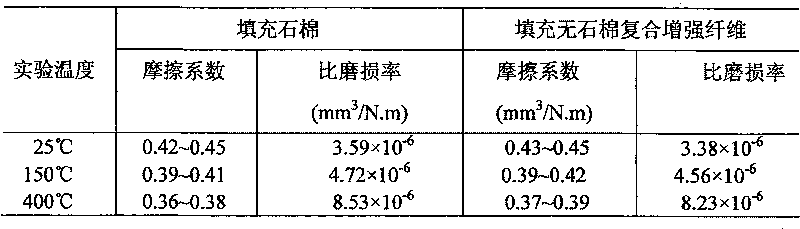

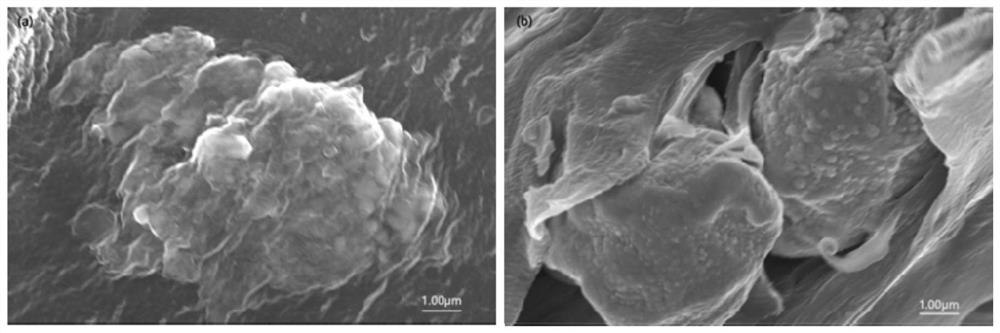

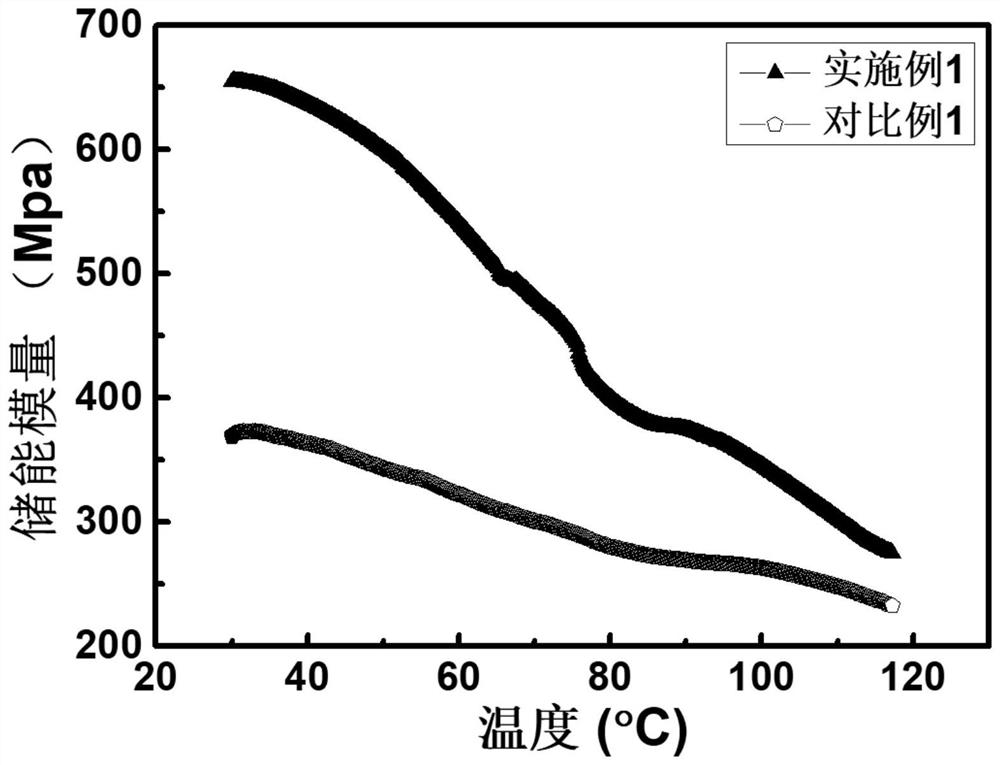

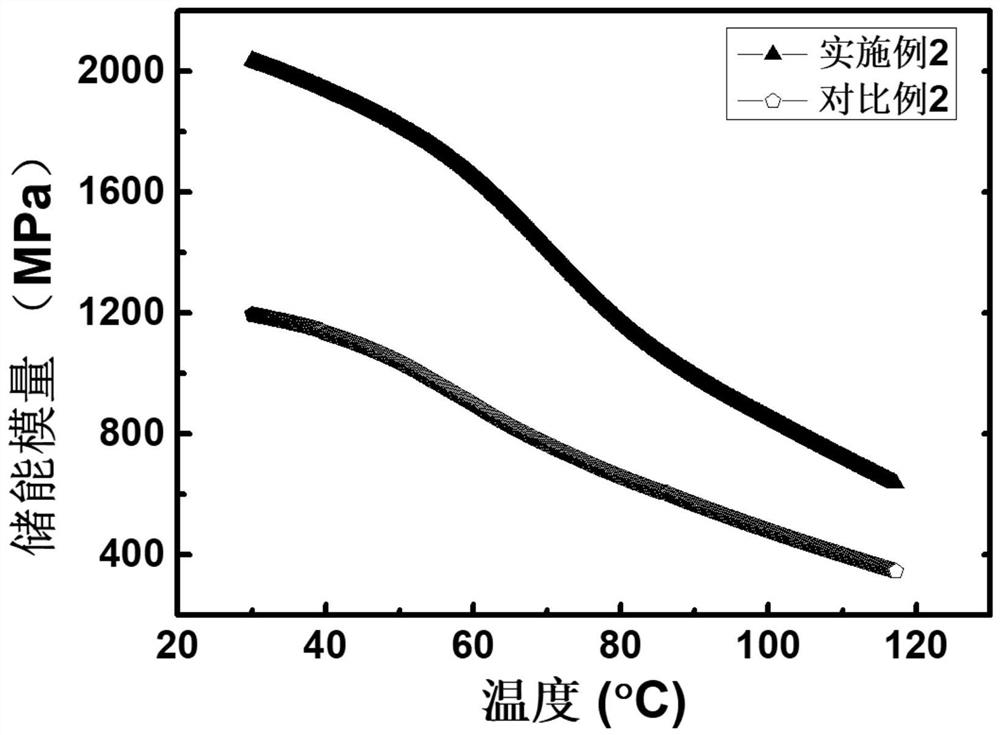

Asbestos-free composite enhancement fibre for friction material and producing technique thereof

InactiveCN101235153BNo pollution in the processEase of mass productionOther chemical processesFiberSlag

The invention provides a new non-asbestos composite reinforced fiber of friction material with low cost and a relative production method, wherein the fiber is environment-friendly, degradable and non-pollution, which can improve the impact strength of friction material. When in use at high temperature, the friction factor is stable with low abrasion. The production method is simple, cheap and suitable for producing friction material. The non-asbestos composite reinforced fiber for friction material contains mine rock wool or gravel-shaped wool of 50-80 parts by weight, fibrilia of 2-10 parts by weight, wood fiber of 3-8 parts by weight, mica powder or ceramic powder of 2-20 parts by weight, and coupling agent or compatibilizer of 1-5 parts by weight. The production method comprises preparing the materials, cutting mine rock wool or gravel-shaped wool, washing via centrifugal machine, removing slag to obtain main fiber, controlling the slag content lower than 0.5-1%, adding fibrilia, wood fiber and mica powder or ceramic powder to be mixed at high speed, drying and spraying coupling agent or compatibilizer, while the drying temperature is 105 to 150 DEG C and the drying time is 1-2h, to obtain composite reinforced fiber.

Owner:韩德忠

Decorative art fruit making method

InactiveCN1840365BDoes not affect developmentEasy to operate and produceSpecial ornamental structuresAlcoholEngineering

The invention discloses a craft ornamental fruit preparing method, which comprises the following steps: using transparent bottle of 2-3cm upper caliber to fill the dropped flower of 0.1-1cm diameter in bottle to grow; fixing the transparent bottle; covering the dark bag over the bottle body until the fruit ripe; shearing the fruit handle part; tying-up the fruit handle root on inner seal ring; hanging the fruit in glass bottle; clearing the fruit with clear water; immersing the 5%-30% blue copperas liquor for 1-9 days; poaching to clean; immersing in the miscible liquids with 5-60ml 1-30% sulfurous acid and 10-60ml 95-99% alcohol. The invention simplifies the operation, which reduces the cost.

Owner:程相喜

Biological organic fertilizer fermentation liquid microbial bacterial agent and preparation method thereof

ActiveCN105543136BFormulation ScienceHeating up fastFungiBacteriaBacillus licheniformisMicrobial agent

The invention provides a bio-organic fertilizer fermented liquid microbial agent. The microbial agent is prepared from bacillus subtilis, bacillus licheniformis, saccharomyces cerevisiae, lactobacilli and aspergillus niger. The bio-organic fertilizer fermented liquid microbial agent has the advantages of being scientific in formula, short in fermentation time, high in enzyme activity, large in viable count, good in deodorization effect and the like, temperature in the fermentation initial stage rises fast, high temperature duration time is long, and protease and cellulase are high in activity and stable. The invention further provides a preparing method of the bio-organic fertilizer fermented liquid microbial agent.

Owner:鹤壁市人元生物技术发展有限公司

A preparation method of high dielectric copper/polyvinylidene fluoride composite material

The invention discloses a preparation method of a high-dielectric copper / polyvinylidene fluoride composite material. The method comprises the following steps: S1, uniformly mixing polyvinylidene fluoride powder with solvent N, N-dimethylformamide to obtain viscous liquid; s2, performing surface treatment on copper, specifically, mixing copper particles and coupling agent L-cysteine in the solventN, N-dimethylformamide for ultrasonic treatment for 10-30 min; s3, pouring the viscous liquid obtained in the step S1 into the mixture obtained in the step S2, and uniformly stirring to obtain a mixedsol; and S4, casting the mixed sol obtained in the step S3 onto a glass slide, scraping into a film, heating to 140-150 DEG C in vacuum, keeping the temperature for 0.5-1.5 hours, and cooling to roomtemperature to obtain the high-dielectric copper / polyvinylidene fluoride composite material. By introducing the new environment-friendly coupling agent, the dispersity of the copper in a polyvinylidene fluoride base is improved, the problem of high dielectric loss of a fine conductive particle / polymer composite material system can be effectively solved, and meanwhile, the dielectric constant is effectively improved.

Owner:SUN YAT SEN UNIV

Silicon mullite iron brick

The invention relates to a silicon mullite iron brick, which can effectively solve the problems of low strength, low wear resistance, low thermal shock resistance and high thermal conductivity. The silicon mullite iron brick is made of the following components in percentage by weight: 10-15 percent of high-aluminum clinker powder with Al2O3 mass content being more than 87 percent and grain size being 2-4mm, 35-40 percent of high-aluminum clinker powder with Al2O3 mass content being more than 87 percent and grain size being 1-2mm, 15-20 percent of silicon carbide powder with SiC mass content being more than 97 percent which passes through a 200-mesh sieve, 8-15 percent of high-iron and high-aluminum clinker powder with Fe2O3 mass content being more than 6 percent which passes through a 300-mesh sieve, 8-13 percent of fused white corundum powder with Al2O3 mass content being more than 98 percent which passes through a 300-mesh sieve, 8-10 percent of soft refractory clay with Al2O3 mass content being more than 30 percent which passes through a 200-mesh sieve, wherein the total of the components is 100 percent. A method for making the silicon mullite iron brick comprises the steps of using the components as basic raw materials and then adding binder. The silicon mullite iron brick has the advantages that the formula is scientific, the raw materials are rich, the method is advanced, the operation and the production are easy to conduct, the product quality is good, the rate of finished products is high, the utilization ratio of raw materials is high, the silicon mullite iron brick can be effectively used for large-sized and medium-sized cement rotary kilns used in the cement production industry, the energy is saved, the environment is protected and the economic and social benefits are remarkable.

Owner:ZHENGZHOU ZHONGBEN KILN MATERIALS

Water-soluble fertilizer using amino acid-microelements chelate

InactiveCN107879803AIncrease profitLow costOrganic fertilisersUrea compound fertilisersWater solubleGibberellin

The invention discloses a water-soluble fertilizer using amino acid-microelements chelate. The fertilizer comprises an absorption enhancer, a fertilizer substrate and a microelement fertilizer. The fertilizer substrate is composed of urea and plant ashes. The mass ratio of the urea and the plant ashes is 20:80, the absorption enhancer is gibberellin, and the mass ratio of the fertilizer substrateand the absorption enhancer is 1000:1. The preparation method of the microelement comprises the steps of placing a protein raw material in a reaction pot, adding 5mol / L of hydrochloric acid, wherein the proportion of the protein raw material and the hydrochloric acid is 1kg:10L, hydrolyzing at 60-70 DEG C temperature for 6-10 hours, and after the hydrolyzing is completed, neutralizing sodium hydroxide and the remnant hydrochloric acid to obtain a compound amino acid water solution. The water-soluble fertilizer using amino acid-microelements chelate is low in cost, easy in operation and production, can enables accurate control of the mass ratio of the microelements, has high use ratio of the microelements, is easily absorbed by plants, does not harm human body and plants, and does not pollute lands.

Owner:岳西县天泰化工有限责任公司

Magnesium powder resmelting recovery method

The present invention relates to a refusion recovery method of magnesium powder, including the following steps: pressing the sub-quality magnesium powder produced in the course of production of magnesium powder into mould, forming refining in refining furnace in which the carnallite solvent, refining agent and magnesium powder are placed, heated to 740 deg.c and melted, standing and cooling, molding, removing surface impurity, soaking with dilute sulfuric acid, washing with clean water and drying by airing. Said invented method is simple and easy to operate, and can ensure quality.

Owner:HENAN HONGYANG INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com