Ozone active oil soft capsule and preparation method and application thereof

A technology of tri-oxygen active oil and soft capsule, applied in the field of medicine, can solve the problems of destruction of normal intestinal flora, damage of alveolar epithelial cells, influence of defecation reflex, etc. The effect of easy storage and transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 3

[0042] The preparation method of embodiment 1 three oxygen oil soft capsules

[0043] 1. Preparation of Trioxygen Oil

[0044] Olive oil 4000mL (density 0.91g / cm 3 ) in a glass container; there are two screw caps on it, one for the inlet of ozone and the other for the outlet of residual ozone, connected to an ozone detector (IDEAL-2000), and using high oxygen liquid The preparation instrument (model ZAMT-Y01) was continuously produced for 9 days, 9 hours a day, that is, a total of 81 hours, the inlet ozone concentration was 100 μg / mL, and the speed was 1 L / min; the outlet ozone concentration was 14.5 μg / mL, and the speed was 1L / min; detect and control the effective conversion rate of ozone by an ozone detector to be 85.5%, and produce ozone oil containing 12% mass percent ozone.

[0045] 2. mix

[0046] Get 60.05% of the trioxygen oil prepared in step 1 by mass percentage and put it into the batching tank, stir while adding, after stirring evenly, filter through 200 mesh, a...

Embodiment 2 3

[0057] The preparation of embodiment 2 three oxygen oil soft capsules

[0058] In an environment of 16°C, use a hyperoxic liquid preparation instrument (model ZAMT-Y01) to continuously produce for 10 days, 11.2 hours a day, that is, a total of 112 hours, the inlet ozone concentration is 100 μg / mL, and the speed is 1L / min; The ozone concentration was 14.5 μg / mL, and the speed was 1 L / min; other operations were the same as in Example 1, and the ozone oil containing 16% by mass of ozone was prepared, and the effective conversion rate of ozone was 85.5%.

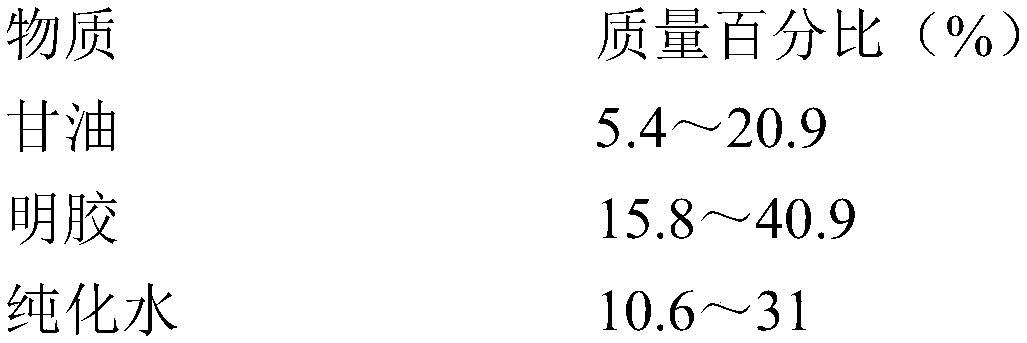

[0059] Take 8.37% of glycerin, 20.92% of gelatin, 20.91% of purified water, and 49.80% of trioxygen oil according to the mass percentage, and obtain the trioxygen oil soft capsule through the preparation method of Example 1.

Embodiment 3 3

[0060] The preparation of embodiment 3 three oxygen oil soft capsules

[0061] In an environment of 16°C, use a hyperoxic liquid preparation instrument (model ZAMT-Y01) to continuously produce for 15 days, 9.8 hours a day, that is, a total of 147 hours, with an inlet ozone concentration of 100 μg / mL and a speed of 1 L / min; The ozone concentration was 14.5 μg / mL, and the speed was 1 L / min; other operations were the same as in Example 1, and the ozone oil containing 20% by mass of ozone was obtained, and the effective conversion rate of ozone was 85.5%.

[0062] Get 20.90% glycerin, 27.50% gelatin, 10.65% purified water, and 40.95% trioxygen oil by mass percentage, and other operations are the same as in Example 1 to obtain trioxygen oil soft capsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com