Coking coal quality improving device and quality improving method

A technology for improving the quality of coal, applied in the direction of grain processing, etc., can solve the problem of not being able to effectively adapt to the requirements of fine-grain and fine-grain sorting and quality improvement of coal in coking, and achieve flexible assembly, easy operation, production and assembly. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

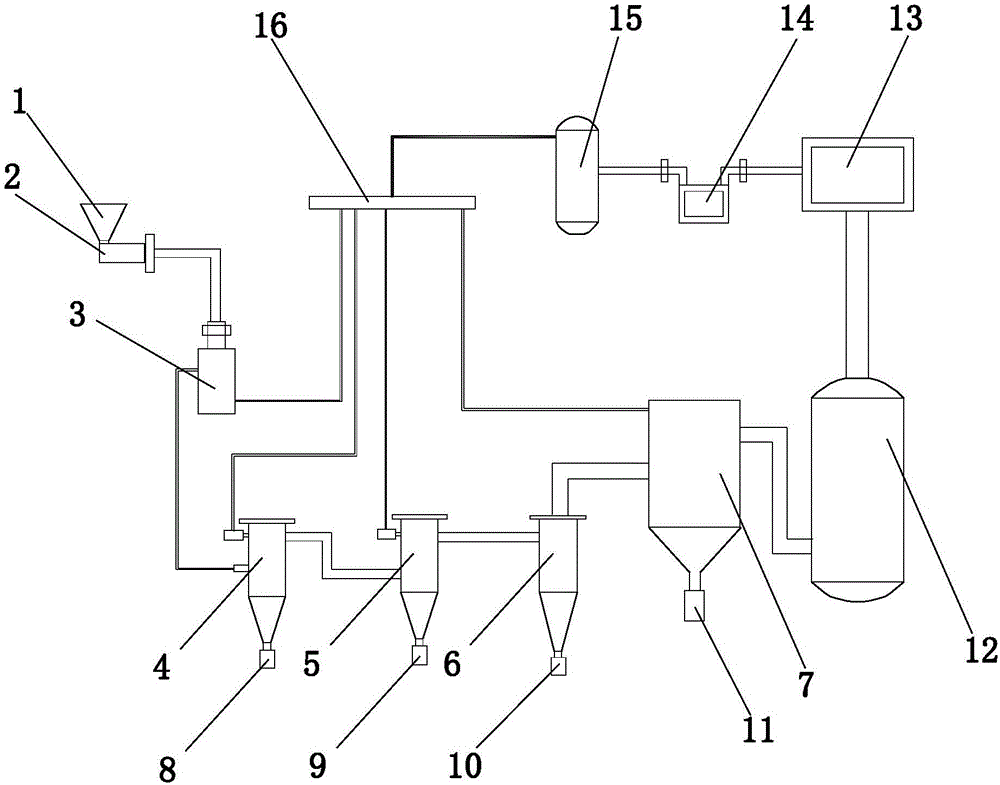

[0031] Such as figure 1 A coal upgrading device for coking is shown, including a quality upgrading mechanism and a wind mechanism;

[0032] The quality improvement mechanism includes a screw feeder 2, a jet mill 3, a primary classifier 4, a secondary classifier 5, a cyclone separator 6 and a bag filter 7 connected in sequence through pipelines. The feeding port of machine 2 is connected with hopper 1;

[0033] The wind mechanism includes a balance tank 12, an air compressor 13, a cold dryer 14, an air storage tank 15 and a distribution valve 16 connected in sequence through pipelines, and the distribution valve 16 is connected to the airflow pulverizer 3 and a The primary classifier 4, the secondary classifier 5 are connected to the bag filter 7, and the bag filter 7 is connected to the balance tank 12 through pipelines.

[0034] Such as figure 1 As shown, the primary classifier 4 is connected to the primary classified product storage tank 8, the secondary classifier 5 is c...

Embodiment 2

[0040] combine figure 1 In this embodiment, the method for upgrading coking medium coal by means of the device described in Example 1 comprises the following steps:

[0041] Step 1, using a jaw crusher to crush the coking medium coal, and then screening the crushed coking medium coal to obtain coking medium coal powder with a particle size of less than 0.125mm;

[0042] Step 2. Add the coking medium coal powder described in step 1 at 84g / min, with a fixed feed rate of 300g each time, into the quality upgrading structure from the hopper 1, and use the wind mechanism to wind the coking medium coal powder. Pushing, the crushing pressure of the jet mill 3 is 0.5MPa, the classification speed of the primary classifier 4 is 6000r / min, and the classification speed of the secondary classifier 5 is 18000r / min, and the quality improvement operation is carried out for 5min to 10min. Finally, the upgraded coking medium coal powder is obtained.

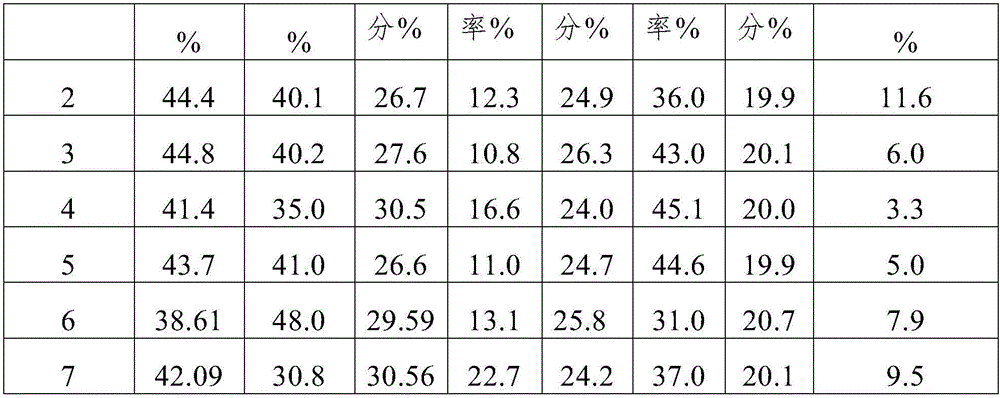

[0043] In this embodiment, the coking coal...

Embodiment 3

[0046] combine figure 1 In this embodiment, the method for upgrading coking medium coal by means of the device described in Example 1 comprises the following steps:

[0047] Step 1, using a jaw crusher to crush the coking medium coal, and then screening the crushed coking medium coal to obtain coking medium coal powder with a particle size of less than 0.125mm;

[0048]Step 2. Add the coking medium coal powder described in step 1 at 84g / min, with a fixed feed rate of 300g each time, into the quality upgrading structure from the hopper 1, and use the wind mechanism to wind the coking medium coal powder. Pushing, the crushing pressure of jet mill 3 is 0.5MPa, the classification speed of primary classifier 4 is 5600r / min, and the classification speed of secondary classifier 5 is 18000r / min, and the quality improvement operation is carried out for 5min~10min. Finally, the upgraded coking medium coal powder is obtained.

[0049] In this embodiment, the coking coal powder after up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com