Production system and production process for producing bricks from pulp sludge

A pulp sludge and production system technology, applied in the field of building materials, can solve problems such as secondary pollution, turning waste into treasure, and affecting the surrounding environment, and achieve the effects of enhancing structural strength, reducing production energy consumption, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

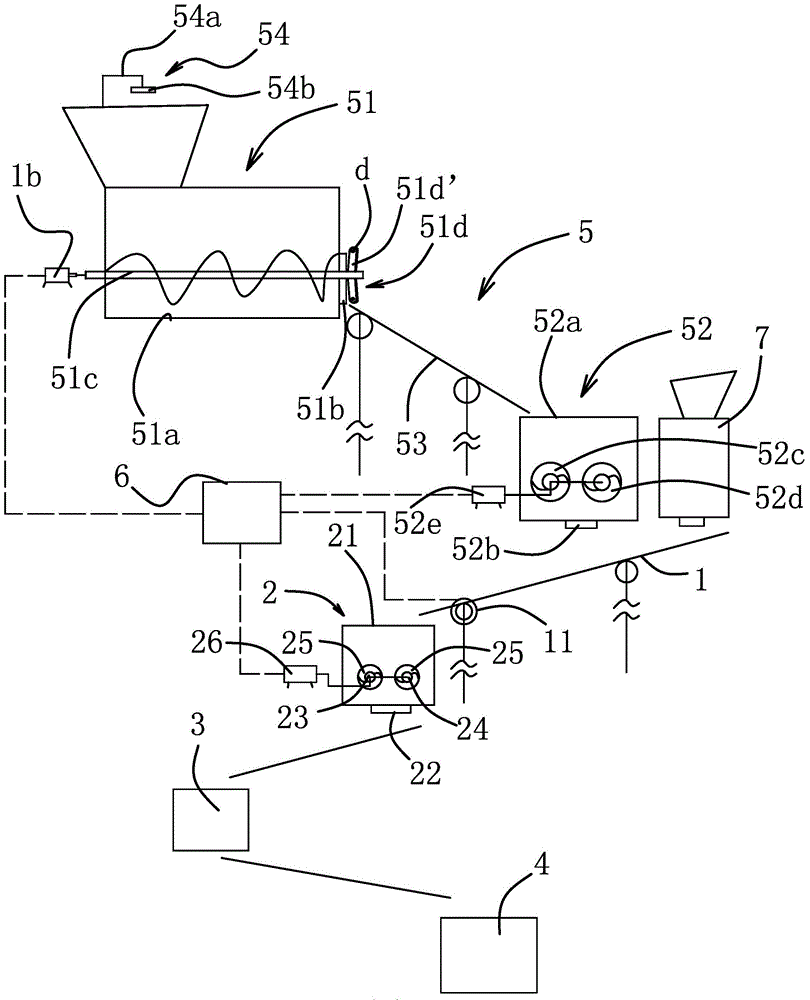

[0040] A kind of production technology that utilizes pulp sludge to produce brick, this production technology comprises the following steps:

[0041] A. Raw material preparation: first cut the pulp sludge into small pieces, then process the small pieces of pulp sludge into small granules, and then mix the small granule pulp sludge and brick-making materials evenly according to a certain proportion, so that The mixed raw material of bricks is obtained; the particle size of small particles is 50-150 mesh;

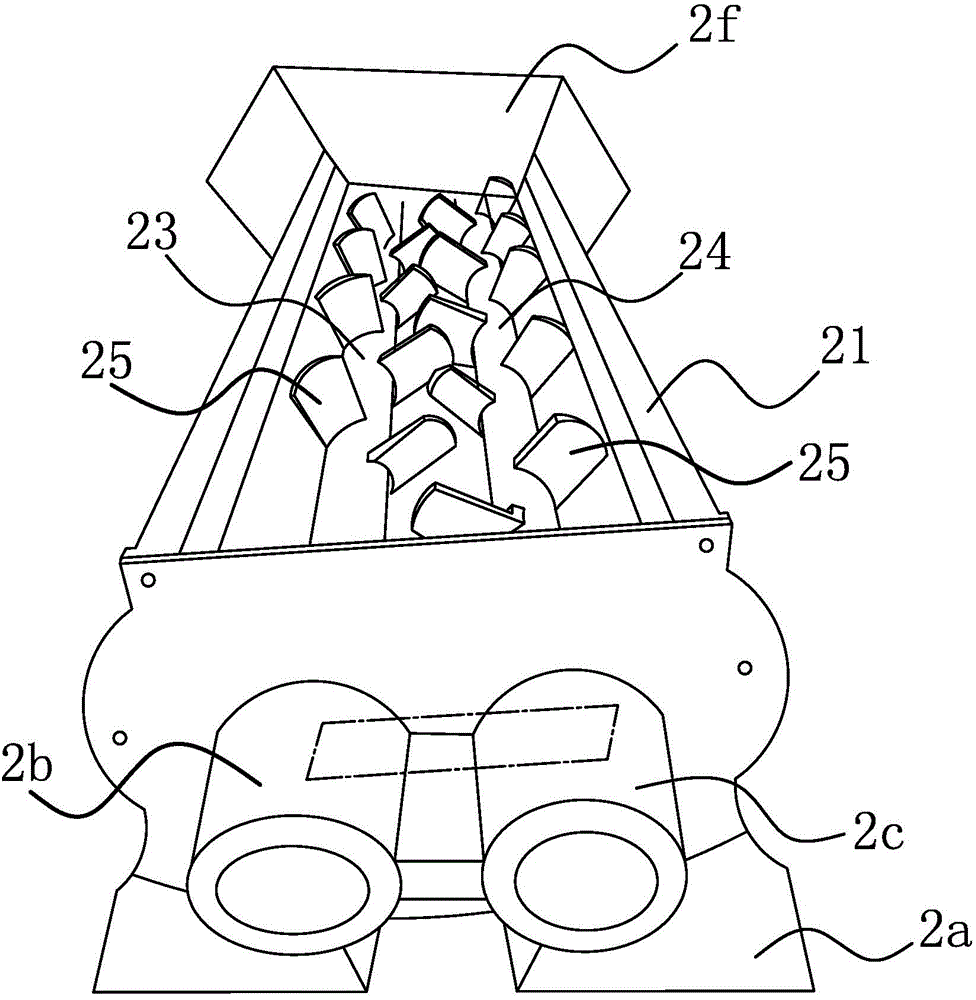

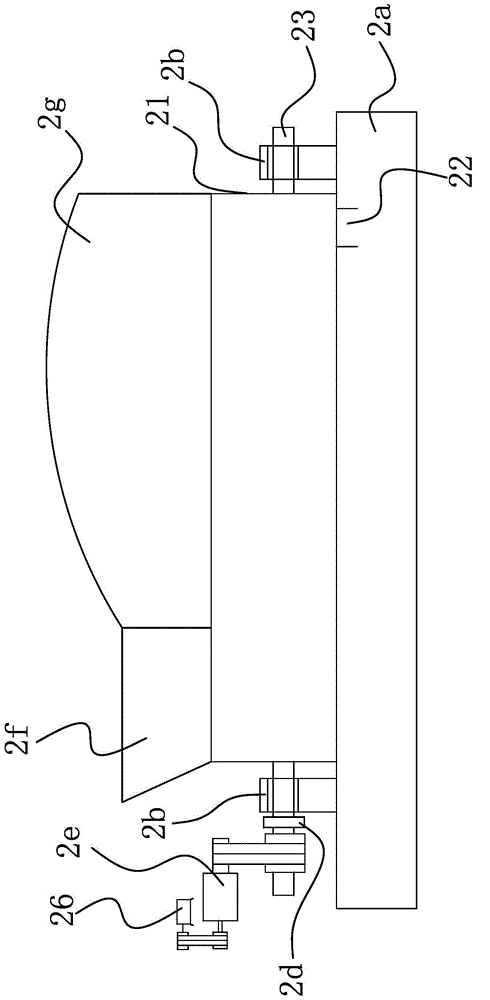

[0042] B. Fermentation treatment: Put the brick mixed raw materials into the stacking bin for 10-15 days;

[0043] C. Brick forming: the fermented brick mixed raw material is stirred, the billet is formed, and the billet is cut to make the brick;

[0044] D. Brick firing: brick adobes are fired through the brick kiln (4) according to the set temperature and time to obtain finished bricks.

[0045] In the above step A, the mixing weight ratio of the brick raw material to the...

Embodiment 2

[0049] The structure and principle of the present embodiment are basically the same as those of the first embodiment, except that no coal powder is added to the brick raw materials of the present embodiment.

Embodiment 3

[0051] The structure and principle of this embodiment are basically the same as those of Embodiments 1 and 2. The difference lies in: fermentation treatment: the brick mixed raw material is put into the stacking bin, and the time for placing it is 10 days; The mixing weight ratio of mud is 1000:0.8; the mixing weight ratio of brick making material and coal powder is 1000:0.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com