Anti-cracking anti-corrosion cable material and preparation method thereof

A technology for cable materials and raw materials, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of poor workability, low hardness, and high cost of insulating materials, and achieve improved crack resistance, high powder fluidity, and safe use. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

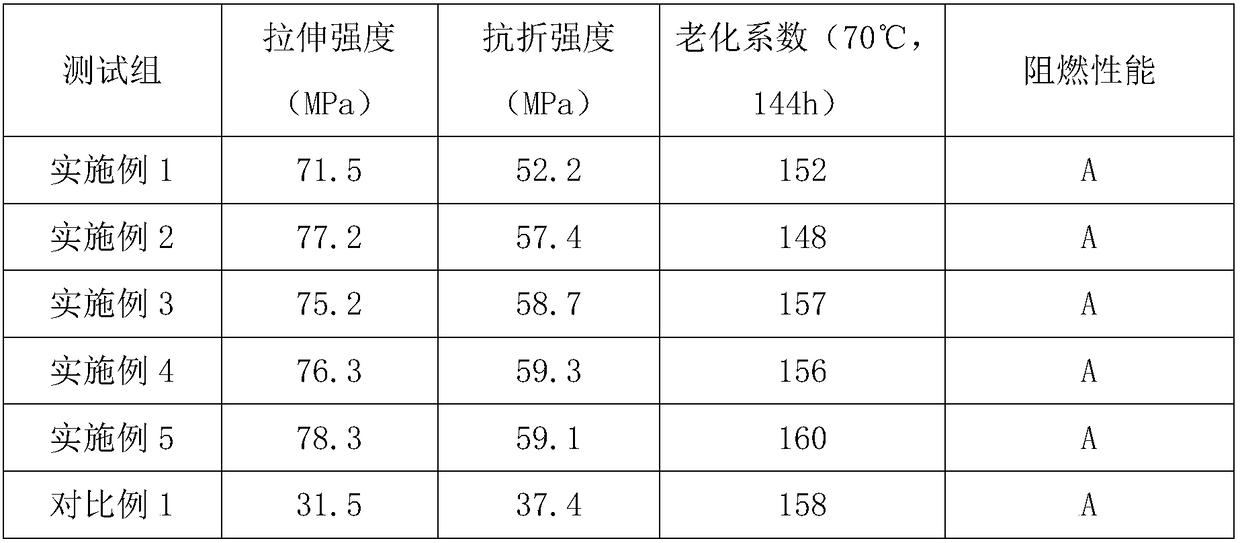

Examples

Embodiment 1

[0032] An anti-crack and anti-corrosion cable material, comprising the following raw materials in parts by weight:

[0033] 50 parts of high-density polyethylene, 18 parts of ethylene-vinyl acetate copolymer, 3 parts of maleic anhydride grafted polyethylene, 5 parts of modified polytetrafluoroethylene particles, 5 parts of nano-titanium dioxide, 22 parts of aluminum hydroxide, 3 parts of chitin 1.8 parts, 1.8 parts of plasticizer and 1.6 parts of antioxidant.

[0034] The preparation method of modified polytetrafluoroethylene particles is as follows:

[0035] (a) After mixing polytetrafluoroethylene fine powder and barium sulfate particles uniformly according to the mass ratio of 3:1, a mixture is obtained; the mixture is added to deionized water, and a surfactant equivalent to 4% by weight is added thereto, After stirring and mixing evenly, heat up to 45 degrees Celsius, and stir and mix for 2 hours at a speed of 1500 rpm;

[0036] (b) at a stirring speed of 1000 rpm, slowl...

Embodiment 2

[0048] An anti-crack and anti-corrosion cable material, comprising the following raw materials in parts by weight:

[0049] 60 parts of high-density polyethylene, 25 parts of ethylene-vinyl acetate copolymer, 8 parts of maleic anhydride grafted polyethylene, 10 parts of modified polytetrafluoroethylene particles, 10 parts of nano-titanium dioxide, 27 parts of aluminum hydroxide, and 8 parts of chitin 4.2 parts, 4.2 parts of plasticizer and 3.5 parts of antioxidant.

[0050] The preparation method of modified polytetrafluoroethylene particles is as follows:

[0051] (a) After mixing polytetrafluoroethylene fine powder and barium sulfate particles uniformly according to the mass ratio of 3:1, a mixture is obtained; the mixture is added to deionized water, and a surfactant equivalent to 4% by weight is added thereto, After stirring and mixing evenly, heat up to 50 degrees Celsius, and stir and mix for 4 hours at a speed of 2000 rpm;

[0052] (b) at a stirring speed of 1000 rpm,...

Embodiment 3

[0064] An anti-crack and anti-corrosion cable material, comprising the following raw materials in parts by weight:

[0065] 52 parts of high-density polyethylene, 20 parts of ethylene-vinyl acetate copolymer, 4 parts of maleic anhydride grafted polyethylene, 6 parts of modified polytetrafluoroethylene particles, 6 parts of nano-titanium dioxide, 23 parts of aluminum hydroxide, 4 parts of chitin 2.5 parts, 2.5 parts of plasticizer and 2.1 parts of antioxidant.

[0066] The preparation method of modified polytetrafluoroethylene particles is as follows:

[0067] (a) After mixing polytetrafluoroethylene fine powder and barium sulfate particles uniformly according to the mass ratio of 3:1, a mixture is obtained; the mixture is added to deionized water, and a surfactant equivalent to 4% by weight is added thereto, After stirring and mixing evenly, heat up to 48 degrees Celsius, and stir and mix for 3 hours at a speed of 1800 rpm;

[0068] (b) at a stirring speed of 1000 rpm, slowl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com