Method for preparing manganese-aluminium hard-magnetic alloy

A hard magnetic alloy, manganese aluminum technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problem of high magnetic performance, achieve the effect of improved magnetic performance, easy operation and production, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] First determine the molecular formula of the manganese-aluminum alloy, calculate the mass percentage of each element (as shown in Table 1) and weigh the corresponding weight (raw material purity: 99wt% or higher). The alloy raw materials smelted in a vacuum induction furnace are used to make ingot billets.

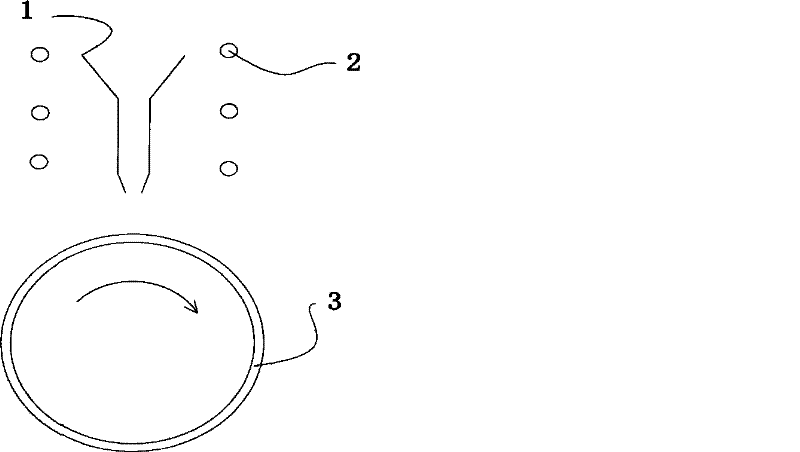

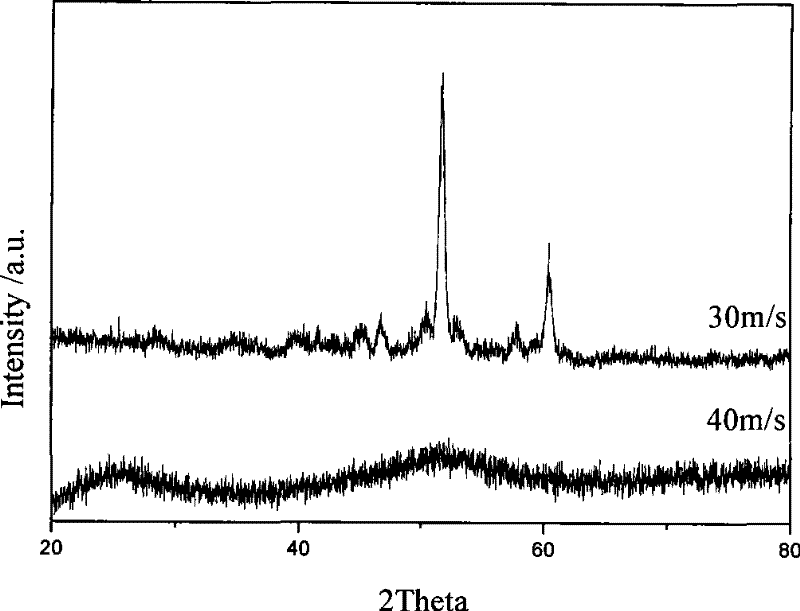

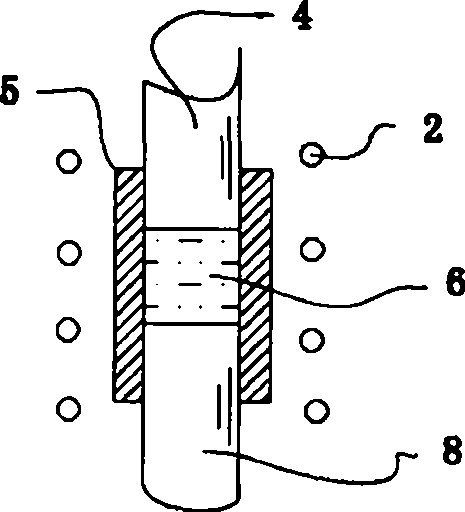

[0039] Using rapid quenching equipment (as shown in Figure 1), the molten alloy is loaded into the crucible 1, the heating source 2 provides heat to the molten state, and poured on the water-cooled copper roller 3 rotating at a peripheral speed of 30 to 50 m / s. close to 10 6 °C / sec. A collection bucket or collection tank can be set in the direction of the alloy thin strip injection. The thickness of the thin alloy strip is about 20-50 μm. The X-ray diffraction pattern of the alloy powder is as figure 2 As shown, when the line speed of the copper roll is 40 m / s, the alloy powder presents an amorphous structure; when the line speed of the copper roll is 20 m / s, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com