A kind of double-sided adhesive product skip small edge processing method

A processing method and double-sided adhesive technology, applied in metal processing and other directions, can solve problems such as product drop, poor product size, and easy displacement of double-sided adhesive, so as to improve work efficiency and facilitate operation and production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

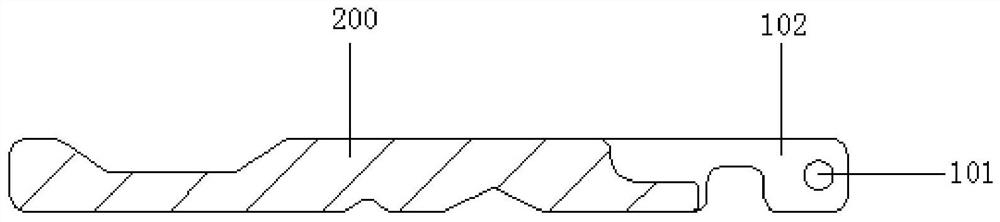

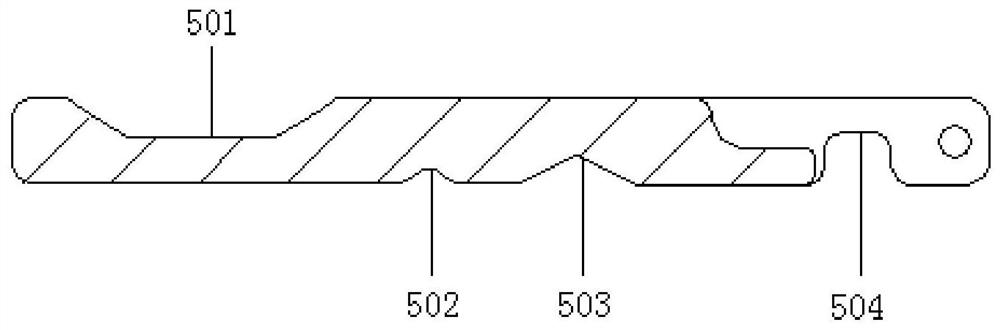

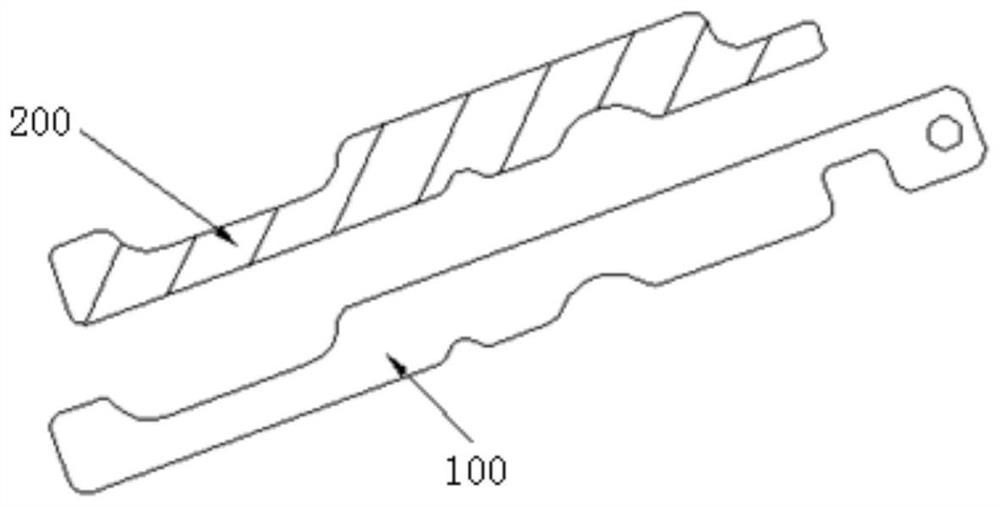

[0039] There is a double-sided adhesive product, such as Figure 1-4 As shown in the figure, the double-sided tape product is a long sheet with irregular edge contours, and the double-sided tape product includes four layers from top to bottom: a handle film 100, a double-sided tape 200, an auxiliary release film 300 and a transparent In the protective film 400, one end of the double-sided tape product is a grasping portion 102 with a circular hole 101. The grasping portion 102 does not include double-sided tape. Along the length direction, one side is provided with a first arc-shaped gap 501, and the other side is respectively A second arc-shaped notch 502 , a third arc-shaped notch 503 and a fourth arc-shaped notch 504 are provided. The length of the first arc-shaped gap 501 is the longest, and the length accounts for 1 / 4 to 1 / 3 of the length of the double-sided tape product. 20. The lengths of the third arc-shaped notch 503 and the fourth arc-shaped notch 504 account for 1 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com