Montmorillonite dry purification process

A technology of dry purification and montmorillonite, which is applied in the field of dry purification of montmorillonite, which can solve problems such as insufficient opening of symbiosis, mosaic, wrapping, montmorillonite cannot be used in the market, and large water consumption. , to achieve the effect of reducing water resources and the application of chemical substances, excellent industrialization prospects, and good continuous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

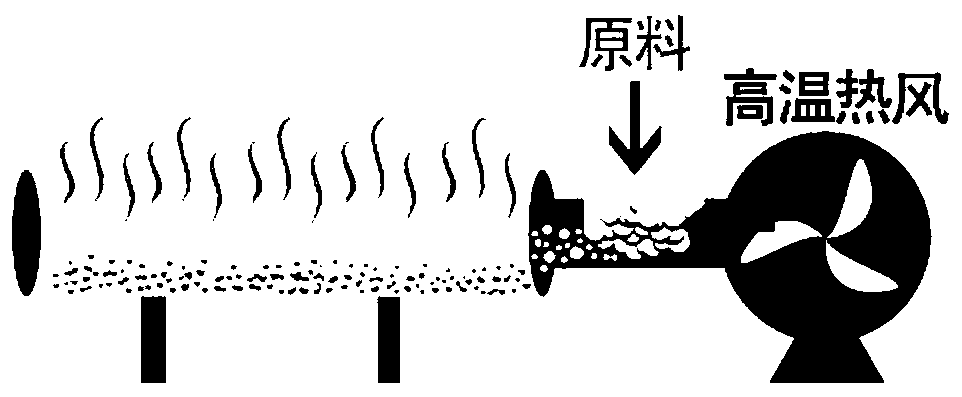

[0026] (1) Disintegrate the lacustrine-origin rhyolite purple ore containing montmorillonite under high-temperature air flow conditions of 800°C and 2m / s to obtain a mixture of impurity particles and montmorillonite particles;

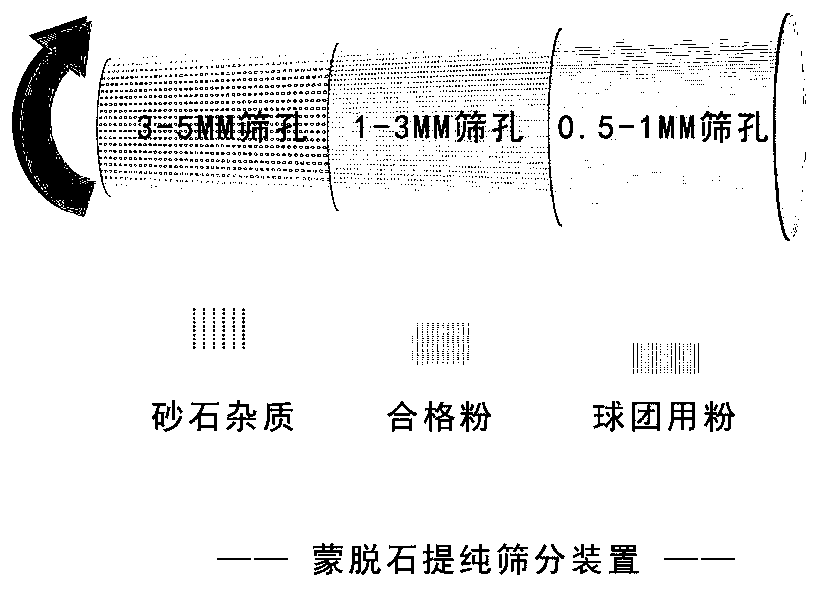

[0027] (2) Heating the mixed particles at 80° C. for 5 minutes in a co-current internal and external heating mode, then measuring the particle size distribution of montmorillonite particles and impurity particles, and designing a screening device with a particle size of 3 mm to sieve the mixed particles;

[0028] (3) Grinding the sieved montmorillonite particles to 350 mesh to obtain montmorillonite fine powder;

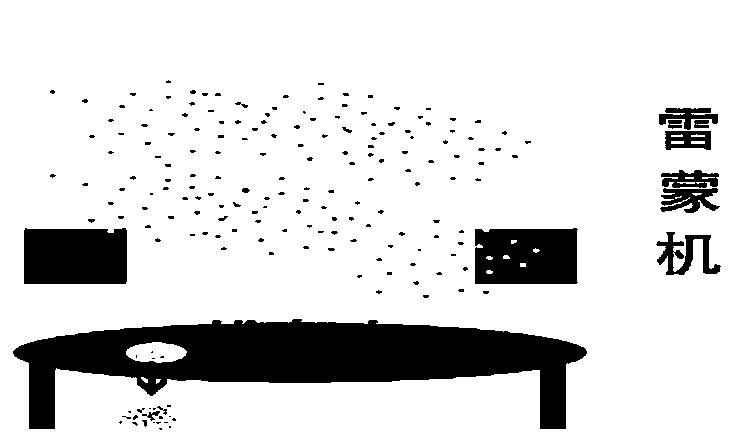

[0029] (4) Grinding the montmorillonite fine powder with a grinding roller wrapped with a vulcanized wear-resistant rubber coating, so that the internal impurities of the montmorillonite fine powder are separated, and then the air flow pressure is adjusted to be 1.2 atmospheric pressure, so that the impurities are settled and removed. Miscell...

Embodiment 2

[0031] (1) Disintegrate the lacustrine-genetic accumulation layer yellow ore containing montmorillonite under the condition of 900°C and 2m / s high-temperature air flow to obtain a mixture of impurity particles and montmorillonite particles;

[0032] (2) Heating the mixed particles at 85° C. for 10 minutes in a concurrent internal and external heating mode, then measuring the particle size distribution of montmorillonite particles and impurity particles, and designing a screening device with a particle size of 1 mm to sieve the mixed particles;

[0033] (3) Grinding the sieved montmorillonite particles to 300 mesh to obtain montmorillonite fine powder;

[0034] (4) Grinding the montmorillonite fine powder with a grinding roller wrapped with a vulcanized wear-resistant rubber coating, so that the internal impurities of the montmorillonite fine powder are separated, and then the air flow pressure is adjusted to be 1.1 atmospheric pressure, so that the impurities are settled and re...

Embodiment 3

[0036] (1) Disintegrate the lacustrine-origin rhyolite light purple ore containing montmorillonite under high-temperature air flow conditions of 850°C and 2m / s to obtain a mixture of impurity particles and montmorillonite particles;

[0037] (2) Heating the mixed particles at 90°C for 5 minutes in a co-current internal and external heating mode, then measuring the particle size distribution of montmorillonite particles and impurity particles, and designing a screening device with a particle size of 2 mm to sieve the mixed particles;

[0038] (3) Grinding the sieved montmorillonite particles to 325 mesh to obtain montmorillonite fine powder;

[0039] (4) Grinding the montmorillonite fine powder with a grinding roller wrapped with a vulcanized wear-resistant rubber coating, so that the internal impurities of the montmorillonite fine powder are separated, and then the air flow pressure is adjusted to be 1.2 atmospheric pressure, so that the impurities are settled and removed. Mis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com