A kind of clay-based composite adsorption material for adsorbing styrene waste gas and its preparation method

A composite adsorption material, styrene technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of low styrene adsorption, cumbersome experimental steps, limited improvement of adsorption performance, etc., and achieve environmental protection preparation costs , The preparation process is simple and the price is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Get 5g of bentonite and add it to 150ml of hydrochloric acid solution with a concentration of 2mol / L, stir, and obtain solution A for 0.5h at room temperature;

[0032] (2) Add 0.005mol fatty alcohol polyoxyethylene ether to solution A, and stir at room temperature for 1 hour to obtain solution B;

[0033] (3) Add 0.15mol ethyl orthosilicate and 0.25g gamma-alumina to solution B, and stir for 20 hours.

[0034] (4) Filter and wash until neutral, dry at 100°C for 12 hours, and grind to 40-80 mesh particles with an agate mortar.

[0035] (5) Dissolve 0.25g of vanadium nitrate in 8.4ml of deionized water, stir for 0.5h, add dropwise on the above-mentioned granules, and stir for 10min. After standing for 4 hours, it was dried at 105°C for 10 hours, and then fired in a muffle furnace at 400°C for 8 hours with a heating rate of 2°C / min.

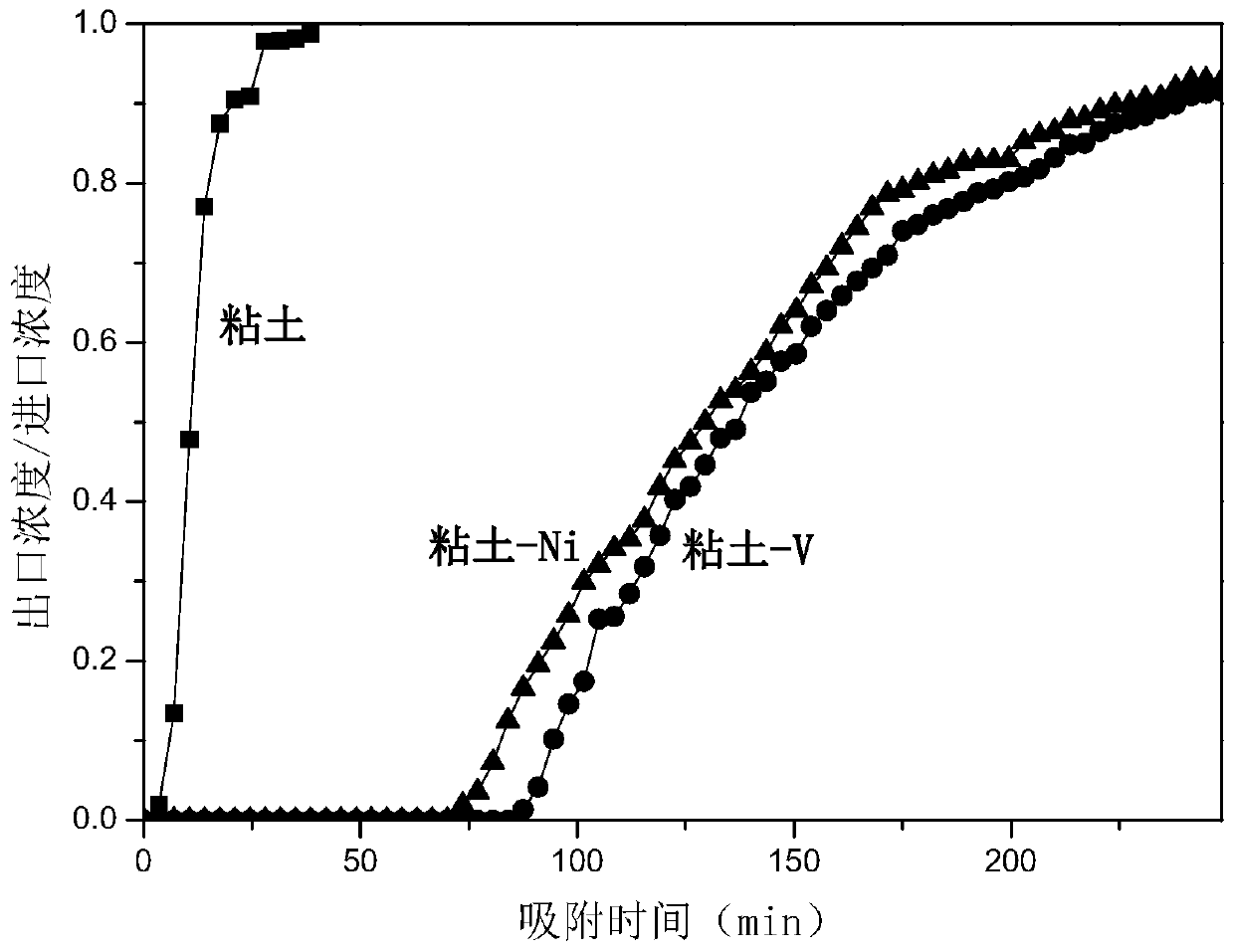

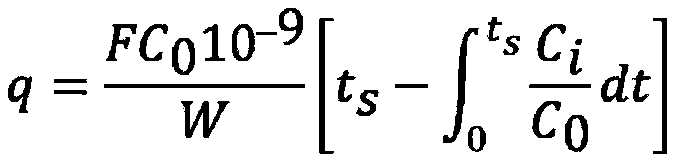

[0036] The prepared new clay composite material is marked as clay-V, the adsorption retention time of styrene is 84min, and the dynam...

Embodiment 2

[0038] (1) Take 5 g of montmorillonite and 5 g of bentonite and add them to 600 ml of sulfuric acid solution with a concentration of 1 mol / L, stir, and obtain solution A at room temperature for 1 h;

[0039] (2) Add 0.0075mol fatty acid polyoxyethylene ester and 0.0025mol polyoxyethylene amine to solution A, and stir at room temperature for 0.5h to obtain solution B;

[0040] (3) Add 0.15 mol of sodium silicate and 1 g of pseudo-boehmite to solution B, and stir for 15 hours.

[0041] (4) Filter and wash until neutral, dry at 100°C for 12 hours, and grind to 40-80 mesh particles with an agate mortar.

[0042](5) Take 1g of chromium nitrate and dissolve it in 33ml of deionized water, stir for 0.5h, add dropwise on the appealing granules, and stir for 10min. After standing for 4 hours, it was dried at 105°C for 10 hours, and then fired in a muffle furnace at 600°C for 2 hours with a heating rate of 10°C / min.

[0043] The prepared new clay composite material is marked as clay-Cr...

Embodiment 3

[0045] (1) Add 6 g of montmorillonite to 200 ml of hydrochloric acid solution with a concentration of 1.5 mol / L, stir, and obtain solution A for 0.5 h at room temperature;

[0046] (2) Add 0.004mol high-carbon fatty alcohol polyoxyethylene ether to solution A, and stir at room temperature for 1 hour to obtain solution B;

[0047] (3) Add 0.1 mol of sodium silicate, 0.2 g of γ-alumina, and 0.2 g of pseudo-boehmite to solution B, and stir for 18 hours.

[0048] (4) Filter and wash until neutral, dry at 100°C for 12 hours, and grind to 40-80 mesh particles with an agate mortar.

[0049] (5) Dissolve 0.45g of ferric nitrate in 15ml of deionized water, stir for 0.5h, add dropwise on the appealing granules, and stir for 10min. After standing for 4 hours, it was dried at 105°C for 10 hours, and then fired in a muffle furnace at 400°C for 8 hours with a heating rate of 3°C / min.

[0050] The prepared new clay composite material is labeled as clay-Fe, the adsorption retention time of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com