Technology for adopting wet process phosphoric acid as raw material to prepare magnesium hydrogen phosphate

A technology of wet-process phosphoric acid and magnesium hydrogen phosphate, applied in the direction of phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low efficiency, high cost of magnesium hydrogen phosphate preparation process, etc., to improve production efficiency, facilitate operation and production, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

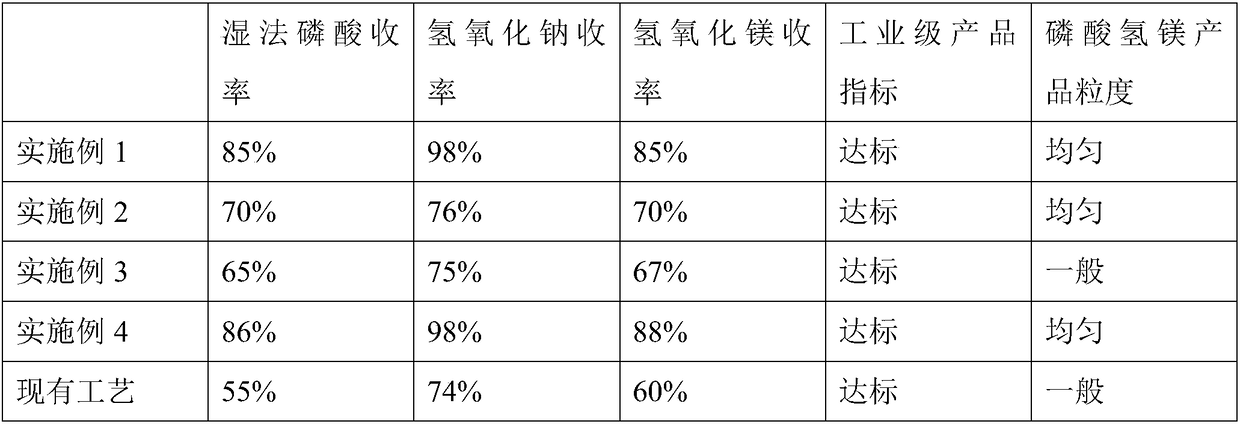

Embodiment 1

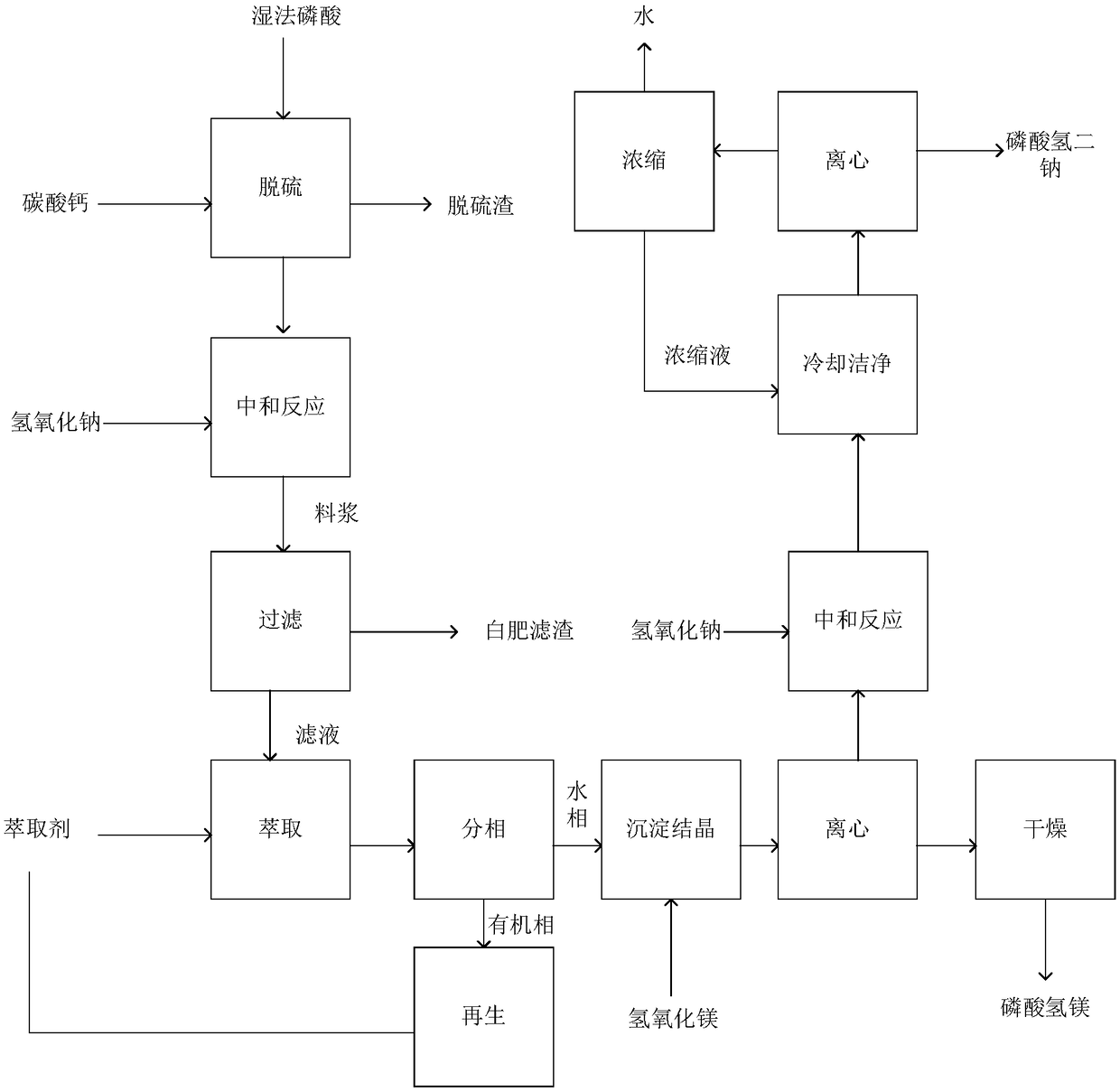

[0033] Such as figure 1 Shown, a kind of adopting wet-process phosphoric acid of the present invention is the technique that raw material produces magnesium hydrogen phosphate, comprises the following steps:

[0034] (1) Add 1.15g of calcium carbonate to 50g of wet-process phosphoric acid for desulfurization in a desulfurized phosphoric acid device, stir for h at 60°C, and stirrer rotation speed 300r / min;

[0035] (2) Add 6.7g sodium hydroxide to desulfurized phosphoric acid, react for 4 hours at a pH of 4.5 and a reaction temperature of 60°C to 70°C, precipitate iron and aluminum phosphate to remove the main impurities, filter the slurry to obtain White manure filter residue;

[0036] (3) Add 35mL P507 extractant to the filtrate to further purify the iron and aluminum impurities in the solution, extract at normal temperature for 10min, separate phases, the water phase enters the next reaction device, and the organic phase regeneration is recovered by the P507 extractant for ...

Embodiment 2

[0040] Include the following steps:

[0041] (1) Add 0.69g of calcium carbonate to 30g of wet-process phosphoric acid and desulfurize in a desulfurized phosphoric acid device, stir at 60°C for 4h, and the rotation speed of the agitator is 300r / min;

[0042] (2) Add 4g of sodium hydroxide to the desulfurized phosphoric acid, and react for 4 hours at a pH of 4.5 and a reaction temperature of 60-70°C to remove the fluosilicic acid in the raw material, and simultaneously precipitate a large amount of iron hydrogen phosphate and aluminum hydrogen phosphate After finishing the reaction, the slurry is filtered to obtain the white fertilizer filter residue;

[0043] (3) Add 35mL P507 extractant to the filtrate to further purify the iron and aluminum impurities in the solution, extract at normal temperature for 10min, separate phases, the water phase enters the next reaction device, and the organic phase regeneration is recovered by the P507 extractant for recycling;

[0044] (4) addi...

Embodiment 3

[0047] Include the following steps:

[0048] (1) Add 1.84g of calcium carbonate to 80g of wet-process phosphoric acid to desulfurize in a desulfurized phosphoric acid device, stir for 4 hours at 60°C, and stirrer rotation speed 300r / min;

[0049] (2) Add 10.7g of sodium hydroxide to the desulfurized phosphoric acid, and react for 4 hours at a pH of 4.5 and a reaction temperature of 60-70°C to remove the fluosilicic acid in the raw material, and simultaneously precipitate a large amount of ferric hydrogen phosphate and hydrogen phosphate aluminum, after finishing the reaction, the slurry is filtered to obtain the white fertilizer filter residue;

[0050] (3) Add 35mL P507 extractant to the filtrate to further purify the iron and aluminum impurities in the solution, extract at normal temperature for 10min, separate phases, the water phase enters the next reaction device, and the organic phase regeneration is recovered by the P507 extractant for recycling;

[0051] (4) adding 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com