Cyclodextrin-metal organic framework (CD-MOF) composite microsphere and preparation method thereof

A metal-organic framework and composite microsphere technology, applied in non-active ingredients medical preparations, microcapsules, pharmaceutical formulations, etc., can solve the problems of drug burst release, structural collapse, easy collapse of CD-MOF, etc., to achieve good protection effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0232] (c) The preparation method of the present invention can maintain the structural integrity of CD-MOF.

[0233] (d) The preparation method of the present invention has simple and controllable process, low cost and good effect.

Embodiment 1

[0239] The prescription is shown in the table below:

[0240]

[0241] The preparation process is as follows:

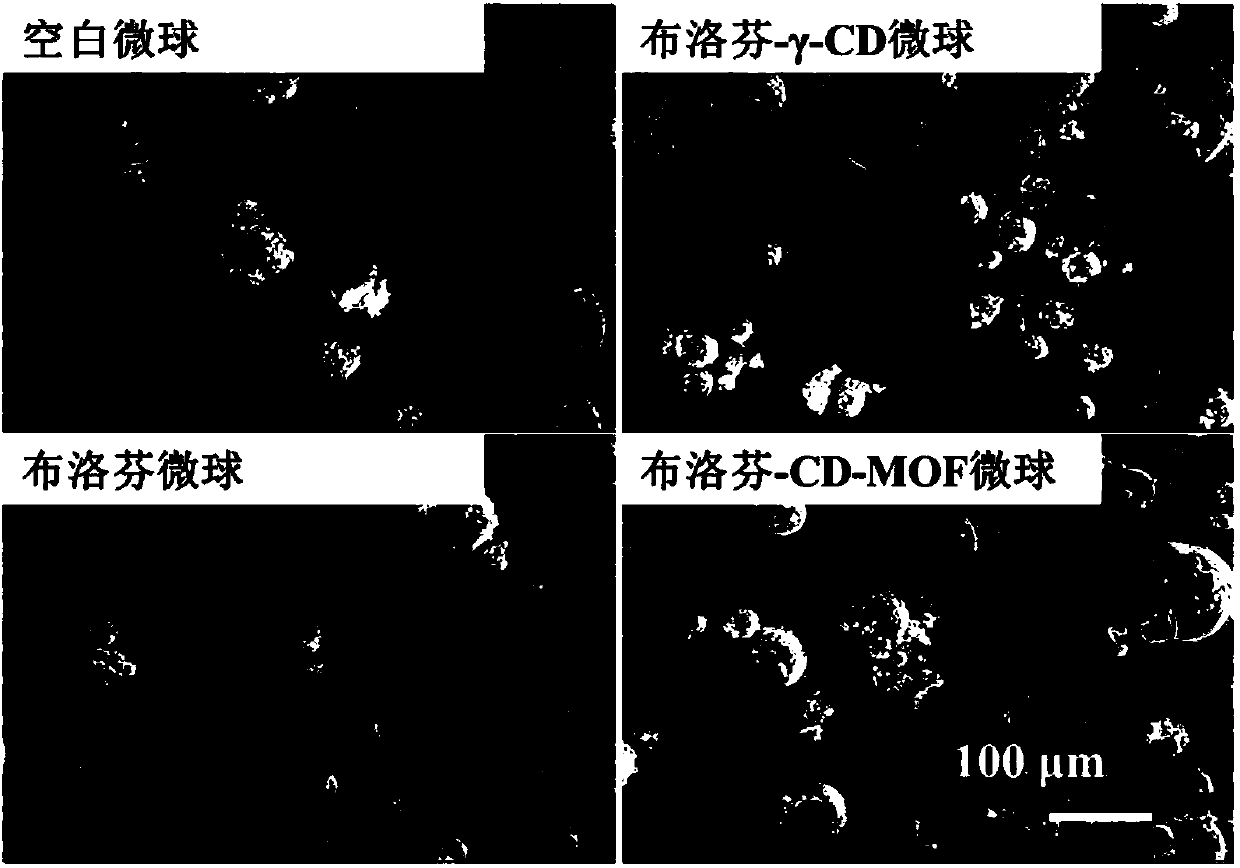

[0242] Weigh 50 mg of ibuprofen-loaded CD-MOF and disperse it in 3 mL of acetone, ultrasonically disperse it evenly, weigh 450 mg of polyacrylic acid resin (MOF: polyacrylic acid resin ratio 1:9, w / w) and dissolve it, then add 120 mg Aluminum stearate (dispersant) is dispersed evenly by ultrasonication for 5 minutes, which is the dispersed phase. Add the dispersed phase containing aluminum stearate to liquid paraffin (ice-bathed to 10°C), place the above suspension in an ice-water bath at 10°C, stir magnetically (500rpm, 30s), and disperse with a disperser (10000rpm, 5min) to obtain an S / O / O type emulsion. Place the above-mentioned emulsion on a magnetic stirrer, and under the condition of 500rpm stirring, slowly raise the temperature from 10°C to 35°C (the setting of magnetic stirring heating is 65, and the heating rate is 10°C·min-1), and then continue to stir...

Embodiment 2

[0245] The prescription is shown in the table below:

[0246]

[0247] The preparation process is as follows:

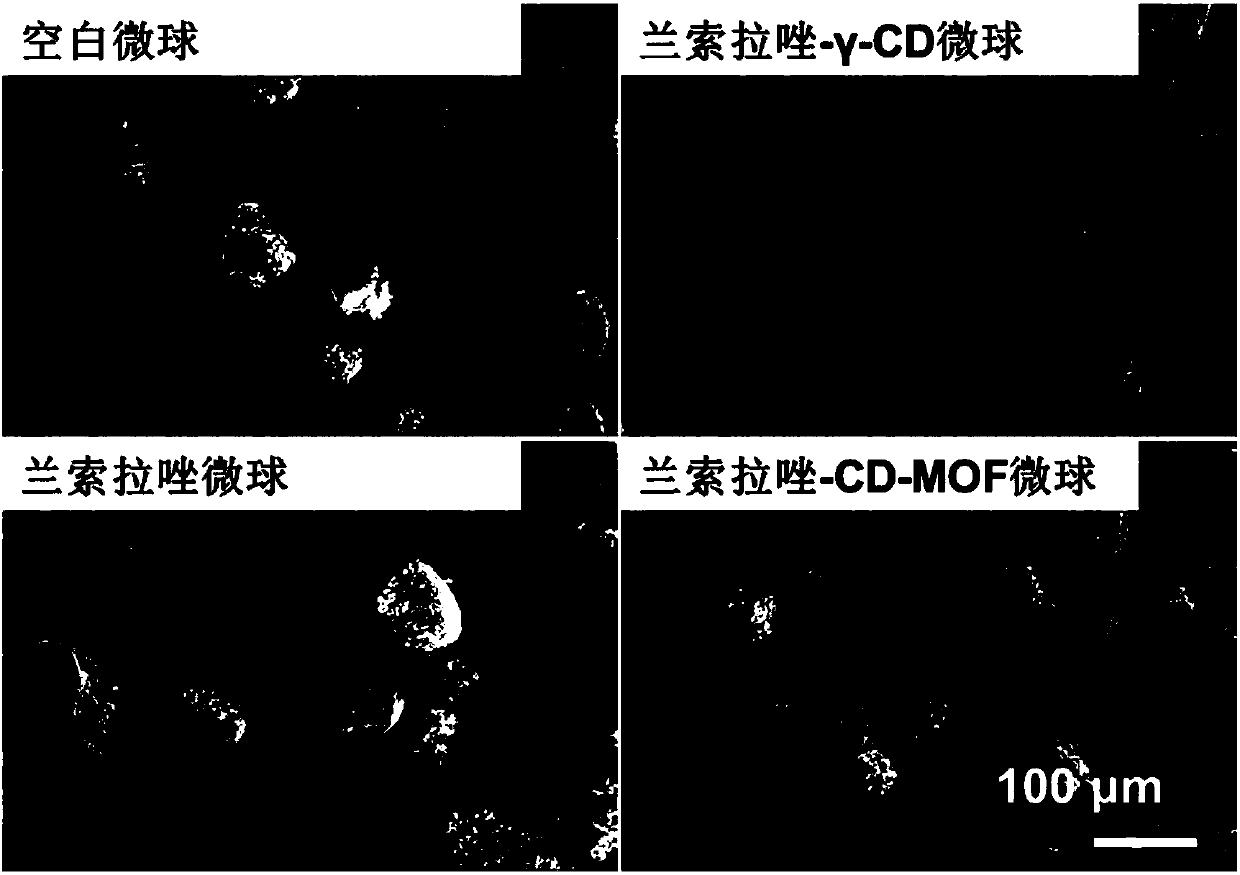

[0248] Weigh 50 mg of lansoprazole-loaded CD-MOF and disperse it in 3 mL of acetone, ultrasonically disperse it evenly, weigh 450 mg of polyacrylic acid resin (MOF: polyacrylic acid resin is 1:9, w / w) and dissolve in it, then add 120mg of aluminum stearate (dispersant) was ultrasonically dispersed for 5 minutes to form a dispersed phase. Add the dispersed phase containing aluminum stearate to liquid paraffin (ice-bathed to 10°C), place the above suspension in an ice-water bath at 10°C, stir magnetically (500rpm, 30s), and disperse with a disperser (10000rpm, 5min) to obtain an S / O / O type emulsion. Place the above-mentioned emulsion on a magnetic stirrer, and under the condition of 500rpm stirring, slowly raise the temperature from 10°C to 35°C (the setting of magnetic stirring heating is 65, and the heating rate is 10°C·min-1), and then continue to stir for 3h (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com