Method for preparing hydroxylapatite ultrafine powder

A technology of hydroxyapatite and ultrafine powder, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problem of large particle size distribution range of products, uniform microscopic mixing of reaction materials, and large differences in reaction environments To achieve the effect of shortening the molecular diffusion distance, reducing the characteristic diffusion time, and realizing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

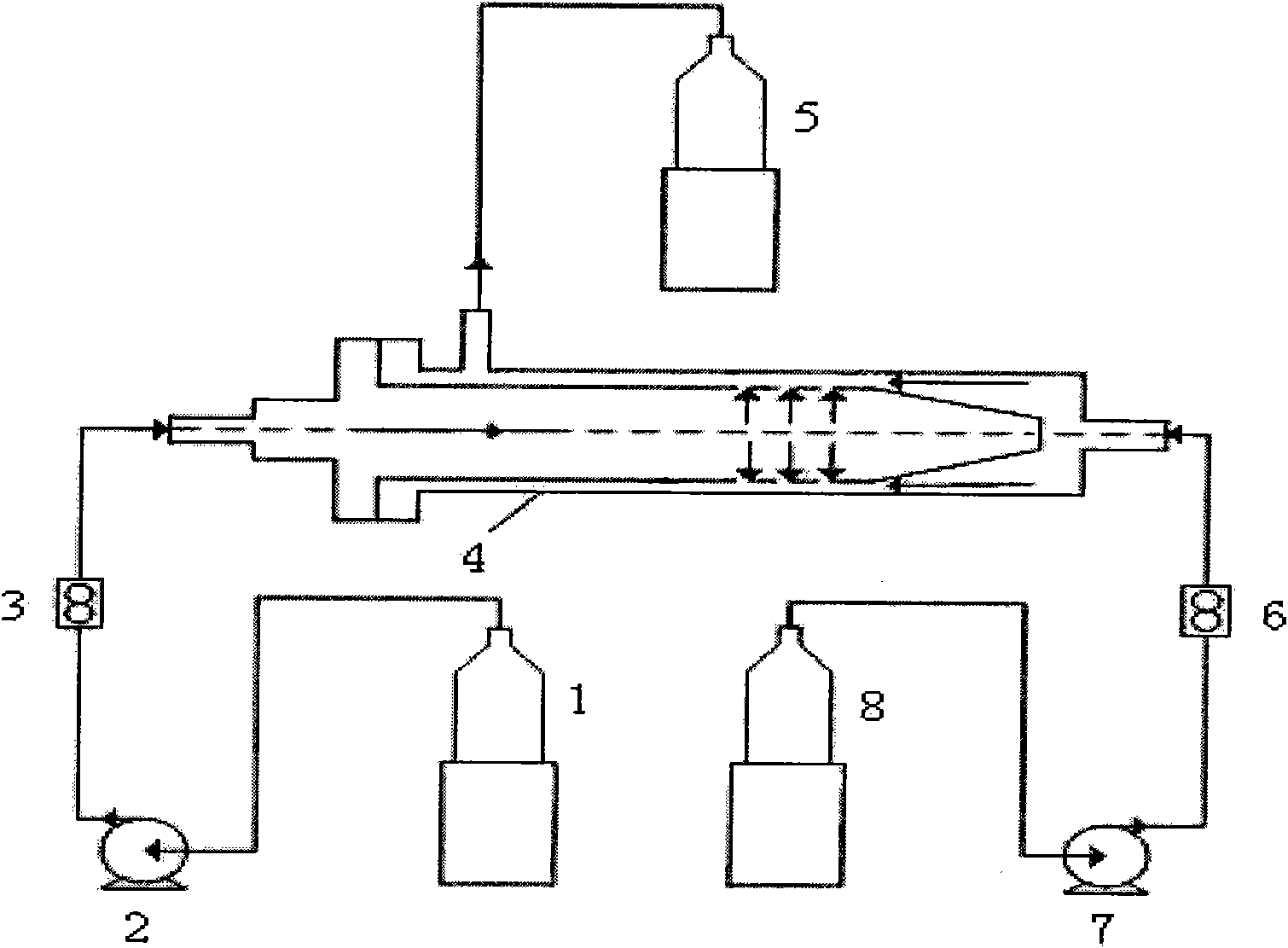

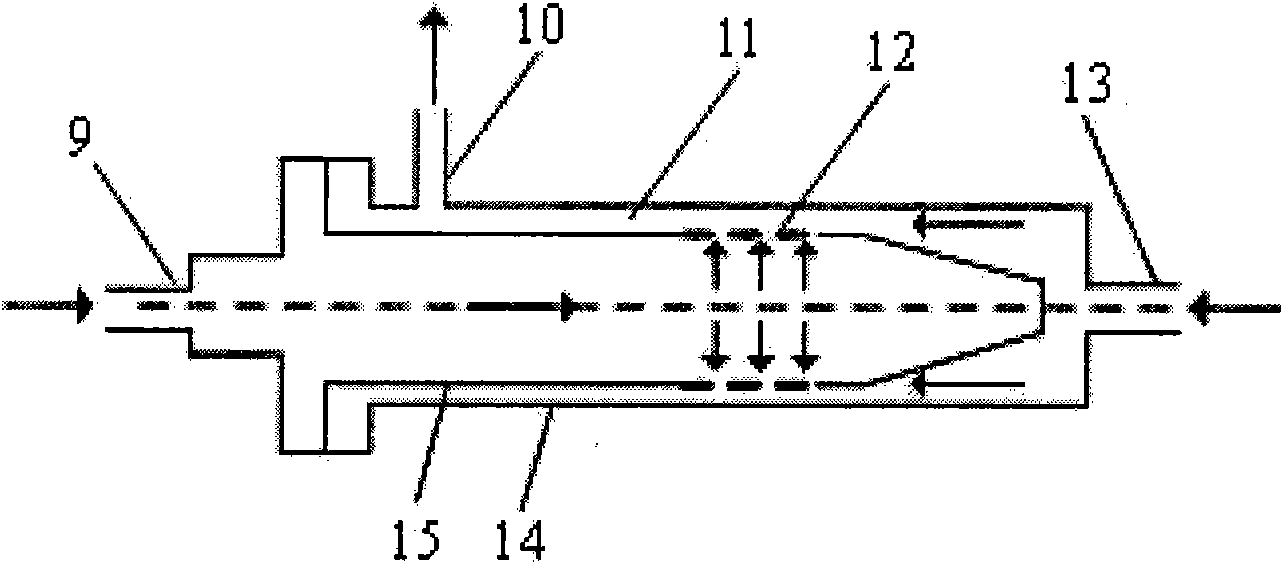

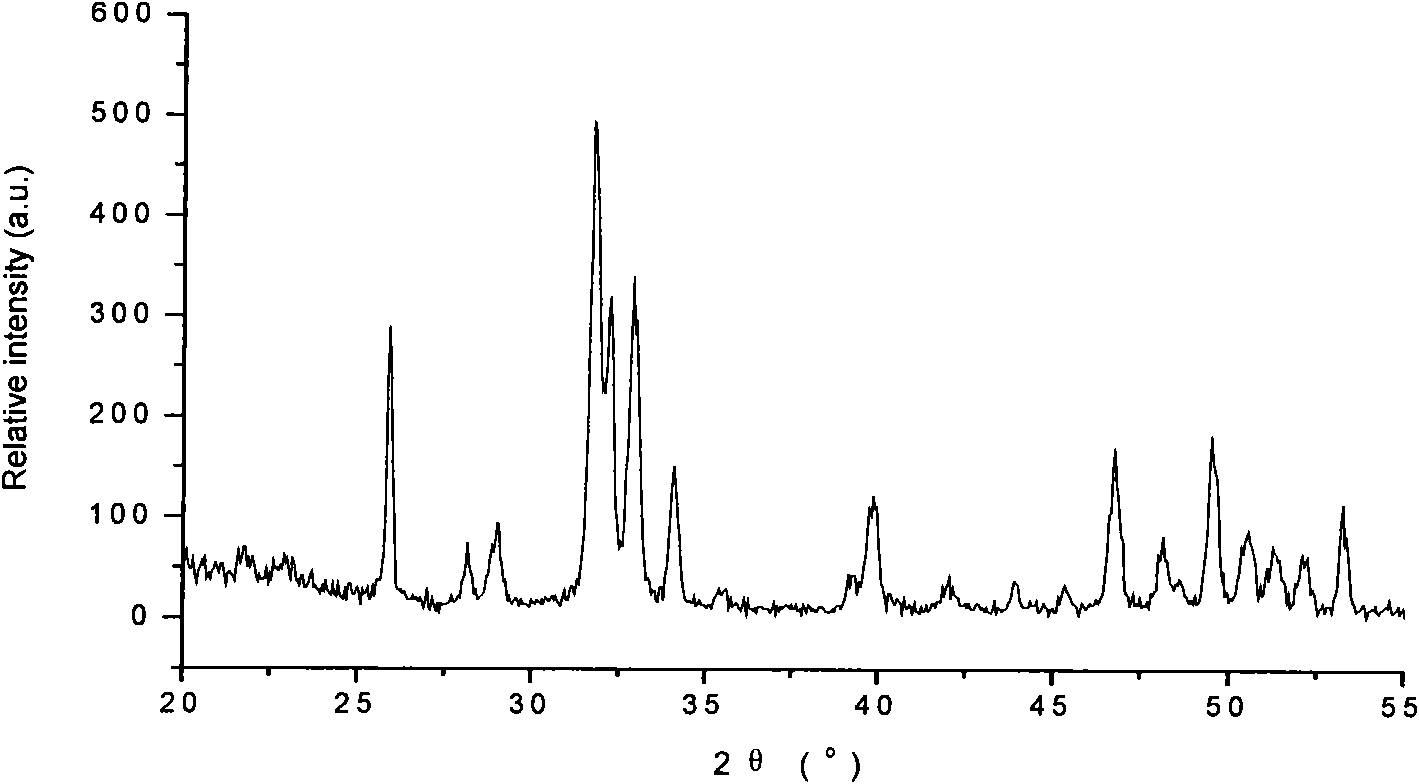

[0034] see figure 1 . At room temperature, put 10 L of diammonium hydrogen phosphate solution with a concentration of 0.2 mol / L into the storage tank 1, put 16.7 L of calcium nitrate solution with a concentration of 0.2 mol / L into the storage tank 8, and add the two solutions respectively An appropriate amount of ammonia water with a mass concentration of 25% is used to adjust the pH value to 9-12. The two solutions are injected into the casing type annular microchannel reactor 4 through the centrifugal pumps 2 and 7 respectively, and the feed flow rates of the two solutions can be adjusted according to the display values of the rotameters 3 and 6 respectively by adjusting Rotating speed is controlled, wherein the feeding flow of diammonium hydrogen phosphate solution is 30L / hr, and the feeding flow of calcium nitrate solution is 50L / hr. After the reaction was completed, the obtained precursor was put into a hydrothermal kettle for hydrothermal treatment at 220°C for 4 hou...

Embodiment 2

[0037] see figure 1 . At room temperature, put 10 L of diammonium hydrogen phosphate solution with a concentration of 0.2 mol / L into the storage tank 1, put 33.3 L of calcium nitrate solution with a concentration of 0.1 mol / L into the storage tank 8, and add the two solutions respectively An appropriate amount of ammonia water with a mass concentration of 25% is used to adjust the pH value to 9-12. The two solutions are injected into the casing type annular microchannel reactor 4 through the centrifugal pumps 2 and 7 respectively, and the feed flow rates of the two solutions can be adjusted according to the display values of the rotameters 3 and 6 respectively by adjusting Rotating speed is controlled, wherein the feeding flow of diammonium hydrogen phosphate solution is 30L / hr, and the feeding flow of calcium nitrate solution is 100L / hr. After the reaction is complete, put the obtained precursor into a hydrothermal kettle for hydrothermal treatment at 220°C for 4 hours, t...

Embodiment 3

[0039] see figure 1 . At room temperature, put 5 L of diammonium hydrogen phosphate solution with a concentration of 0.4 mol / L into the storage tank 1, put 50 L of calcium nitrate solution with a concentration of 0.0667 mol / L into the storage tank 8, and add an appropriate amount of the two solutions respectively The mass concentration is 25% ammonia water to adjust the pH value to 9-12. The two solutions are injected into the casing type annular microchannel reactor 4 through the centrifugal pumps 2 and 7 respectively, and the feed flow rates of the two solutions can be adjusted according to the display values of the rotameters 3 and 6 respectively by adjusting Rotating speed is controlled, wherein the feeding flow of diammonium hydrogen phosphate solution is 15L / hr, and the feeding flow of calcium nitrate solution is 150L / hr. After the reaction is complete, put the obtained precursor into a hydrothermal kettle for hydrothermal treatment at 220°C for 4 hours, then rinse t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com