Non-spherical polymer particles uniform in particle size as well as preparation method and application of non-spherical polymer particles

A polymer particle, non-spherical technology, applied in the field of polymer materials, can solve the problems of difficulty in obtaining nano-scale particles, non-spherical polymer particles not suitable for hydrophilic drug embedding, and cumbersome process of non-spherical polymer particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

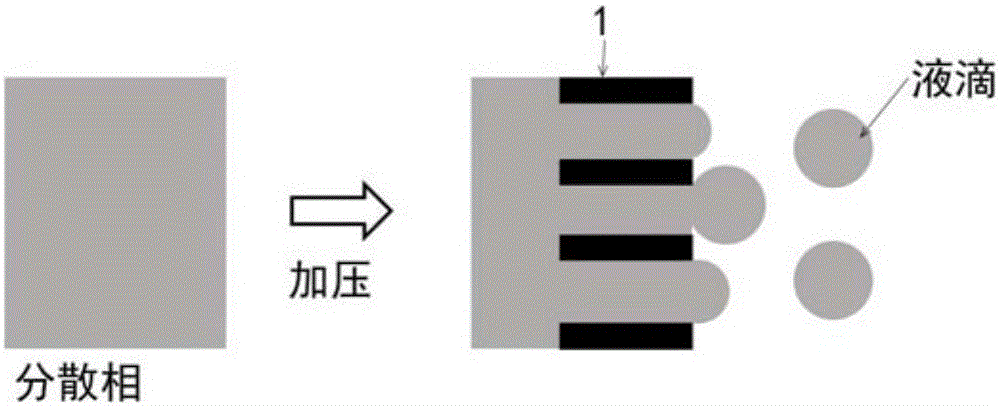

[0150] Example 1: Preparation of non-spherical PLGA particles by direct membrane emulsification

[0151] First, 100mg PLGA (molecular weight is 13kDa, the polymerization ratio of LA:GA is 20:80) is dissolved in 4mL dichloromethane as the oil phase, 0.25mL ultrapure water is added to the oil phase as the internal water phase, and the The primary emulsion was prepared with an ultrasonic breaker with a power of 80W and an ultrasonic time of 30s. Then the colostrum is poured into the direct membrane emulsifier liquid storage bottle, under the nitrogen pressure of 50kPa, the colostrum is hydraulically passed through a microporous ceramic membrane with a membrane aperture of 1.8 μm into 400mL containing 0.1wt.%PVA and 0.08mol / L phosphoric acid In the aqueous solution of disodium hydrogen, magnetically stir at 250rpm for more than 4h to make the solvent dichloromethane volatilize naturally. The solidified solution was centrifuged and washed 4 times with deionized water, and the conc...

Embodiment 2

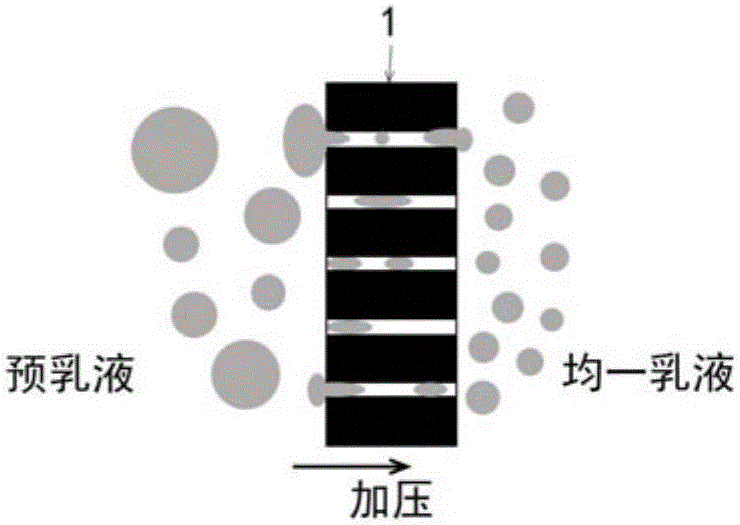

[0161] Example 2: Preparation of non-spherical PELA particles by rapid membrane emulsification

[0162] First, 300 mg of PELA (molecular weight 40 kDa, mPEG:PLA=1:19) was dissolved in 2 mL of dichloromethane as the oil phase, and 0.1 mL of ultrapure water containing 0.1 wt % Tween80 was added to the oil phase as the internal water phase, and the Under the conditions, the first emulsion was prepared with an ultrasonic breaker, the power was 80W, and the ultrasonic time was 30s. Then pour the primary emulsion into 50mL aqueous solution containing 0.1wt.% Tween80 and 0.001mol / L disodium hydrogen phosphate, prepare the pre-multiplex emulsion by homogenizing at 1000rpm for 30s, then pour it into the liquid storage bottle of the rapid membrane emulsifier, under 10kPa Under nitrogen pressure, the pre-complex emulsion was hydraulically passed through a microporous polytetrafluoroethylene membrane with a membrane pore size of 20 μm, and a uniform emulsion was obtained after repeated pa...

Embodiment 3

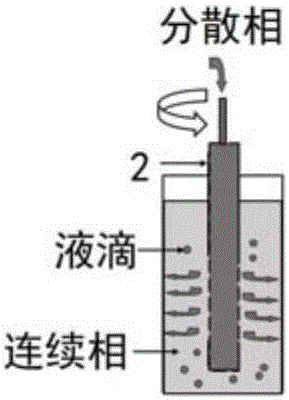

[0171] Example 3: Preparation of non-spherical PLA particles by rotating membrane emulsification method

[0172] First, 100mg PLA (molecular weight 70kDa) was dissolved in 3mL of dichloromethane as the oil phase, 0.5mL of ultrapure water containing 5mg / mL octreotide and 0.2wt% Tween 80 was added as the inner water phase into the oil phase, and used under ice-bath conditions. The homogenizer prepares the primary emulsion, the rotation speed is 3000rpm, and the time is 60s. Then the primary emulsion is poured into the rotating membrane emulsifier liquid storage tank, with 500rpm rotating stainless steel microporous membrane (the membrane aperture is 30 μ m), the primary emulsion enters the outer water phase (200mL contains 1wt% Tween80 and 0.08mol / L aqueous solution of disodium hydrogen phosphate) to obtain a double emulsion, solidify overnight with magnetic stirring at 300rpm at room temperature, and make the solvent dichloromethane volatilize naturally. The solidified solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com