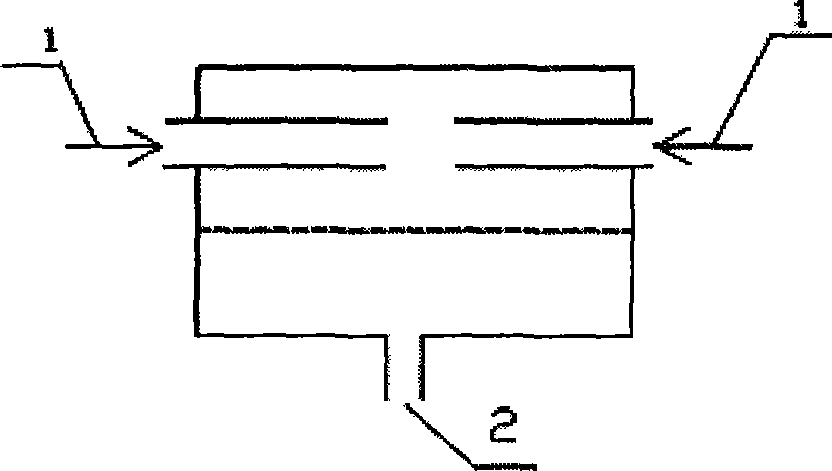

Method for preparing positive electrode material of Li-ion battery using impact-flow equipment

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, circuits, electrode manufacturing, etc., can solve the problems of impinging flow reaction, low electrochemical capacity, and long reaction cycle, etc., to improve electrochemical capacity and reaction efficiency High, short response time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Lithium nitrate and manganese nitrate are weighed according to Li:Mn=1:1, dissolved in deionized water respectively to make a solution, and the two solutions collide with each other and react in the impinging flow device at a speed of 2m / s. An appropriate amount of sodium carbonate was added to the impingement flow device to adjust the pH to 10. The obtained precipitate was washed and dried, then transferred to a high-temperature furnace, calcined at 600°C for 12 hours, and cooled to obtain LiMn 2 o 4 Cathode material. The electrochemical capacity of the product is 120mAh / g, and the cycle performance is excellent.

Embodiment 2

[0034] Lithium nitrate and manganese nitrate were weighed according to Li:Mn=1.03:1, respectively dissolved in deionized water to make a solution, and the two solutions collided with each other in the impinging flow device at a speed of 10m / s and reacted. An appropriate amount of sodium carbonate was added to the impinging flow device to adjust the pH to 10. The obtained precipitate was washed and dried, then transferred to a high-temperature furnace, and calcined at 600 ° C for 10 h to obtain LiMn 2 o 4 Cathode material. The electrochemical capacity of the product is 122mAh / g, and the cycle performance is excellent.

Embodiment 3

[0036] Lithium nitrate and nickel nitrate were weighed at a molar ratio of Li:Ni=1:1, and were dissolved in deionized water to make a solution. The two solutions collided with each other in the impinging flow device at a speed of 7m / s and reacted. The obtained precipitate was washed and dried, then transferred to a high-temperature furnace, calcined at 700 ° C for 10 h, and cooled to obtain LiNiO 2 Cathode material, the particle size of the product is small and uniform, the electrochemical capacity reaches 170mAh / g, and the cycle performance is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com