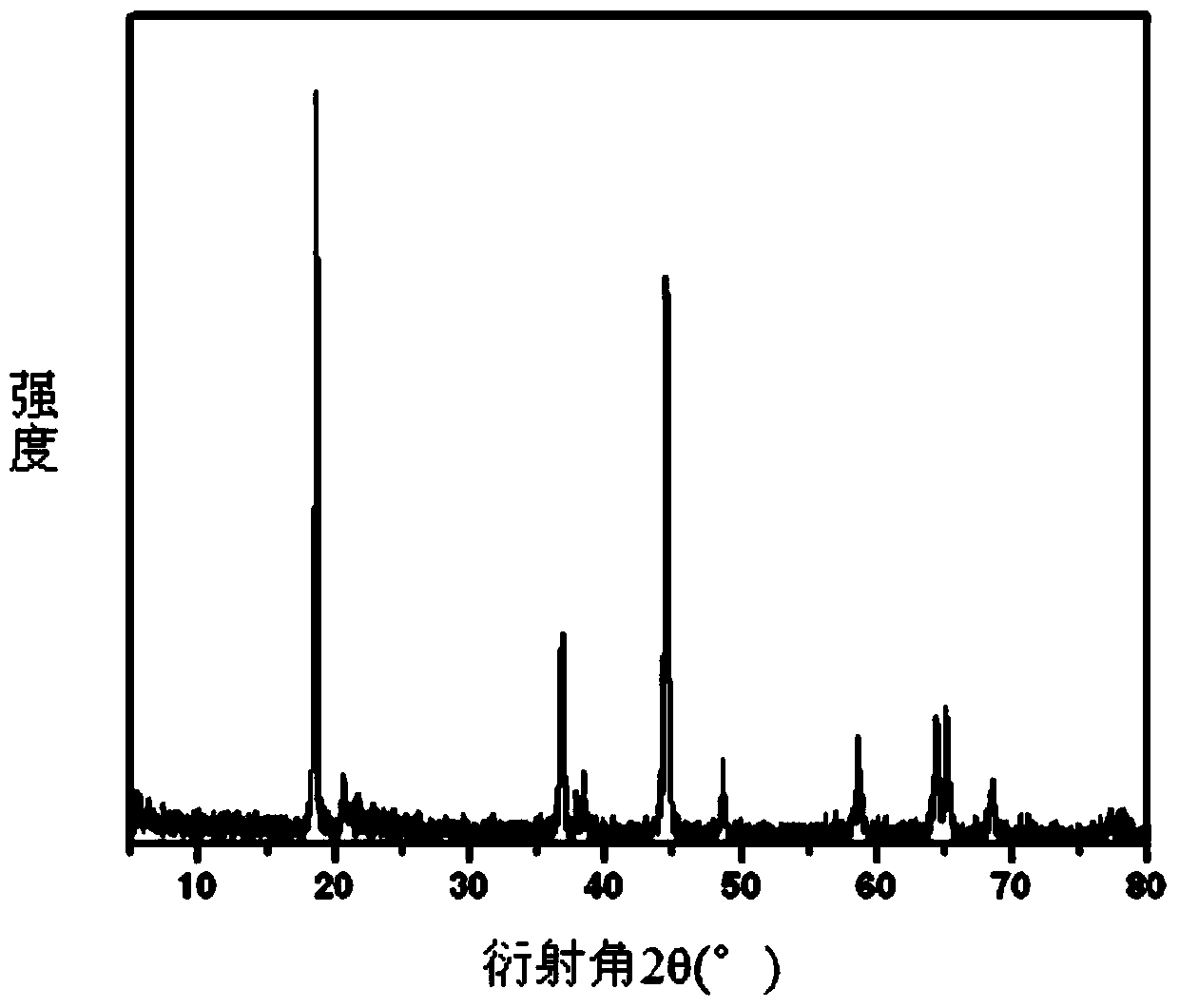

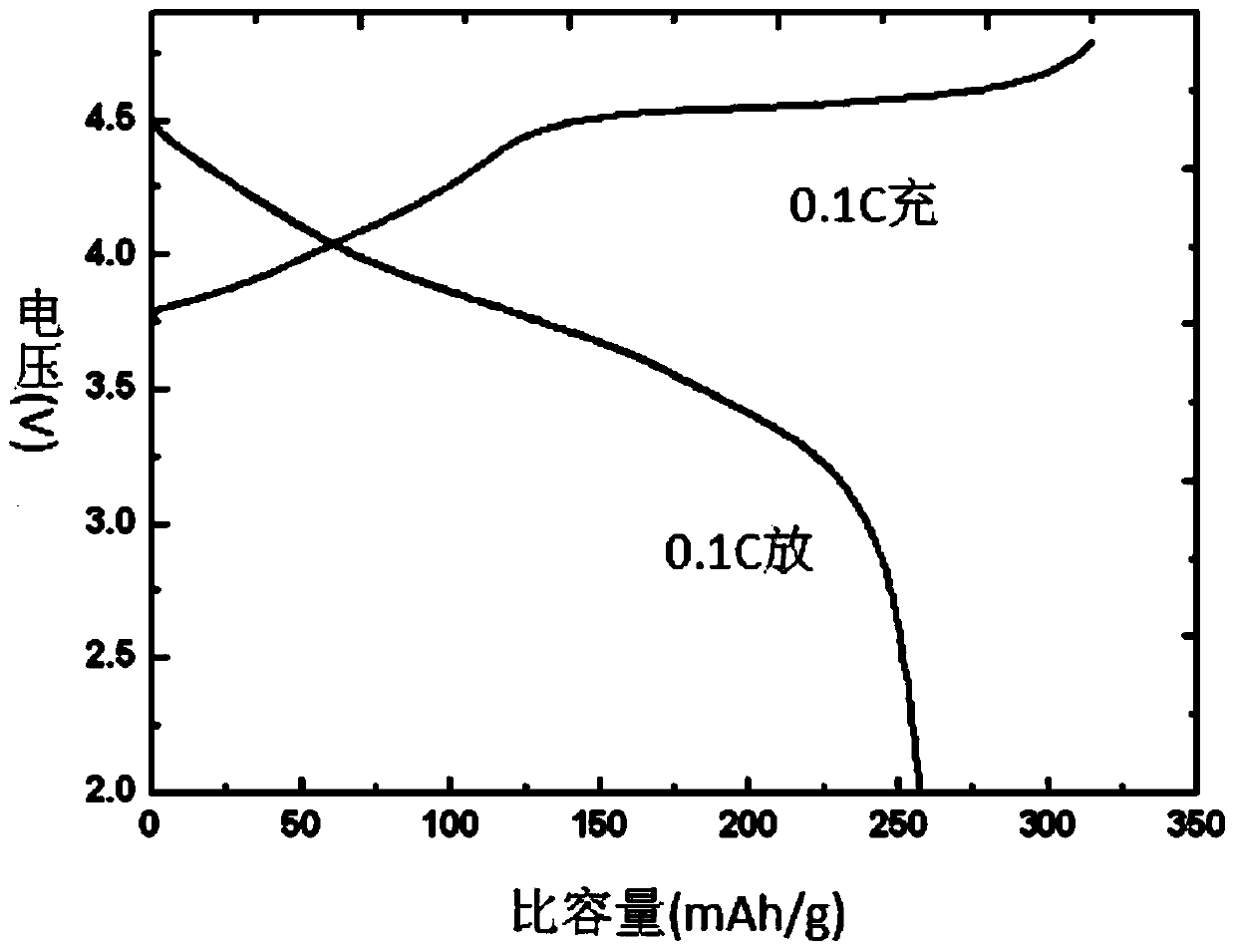

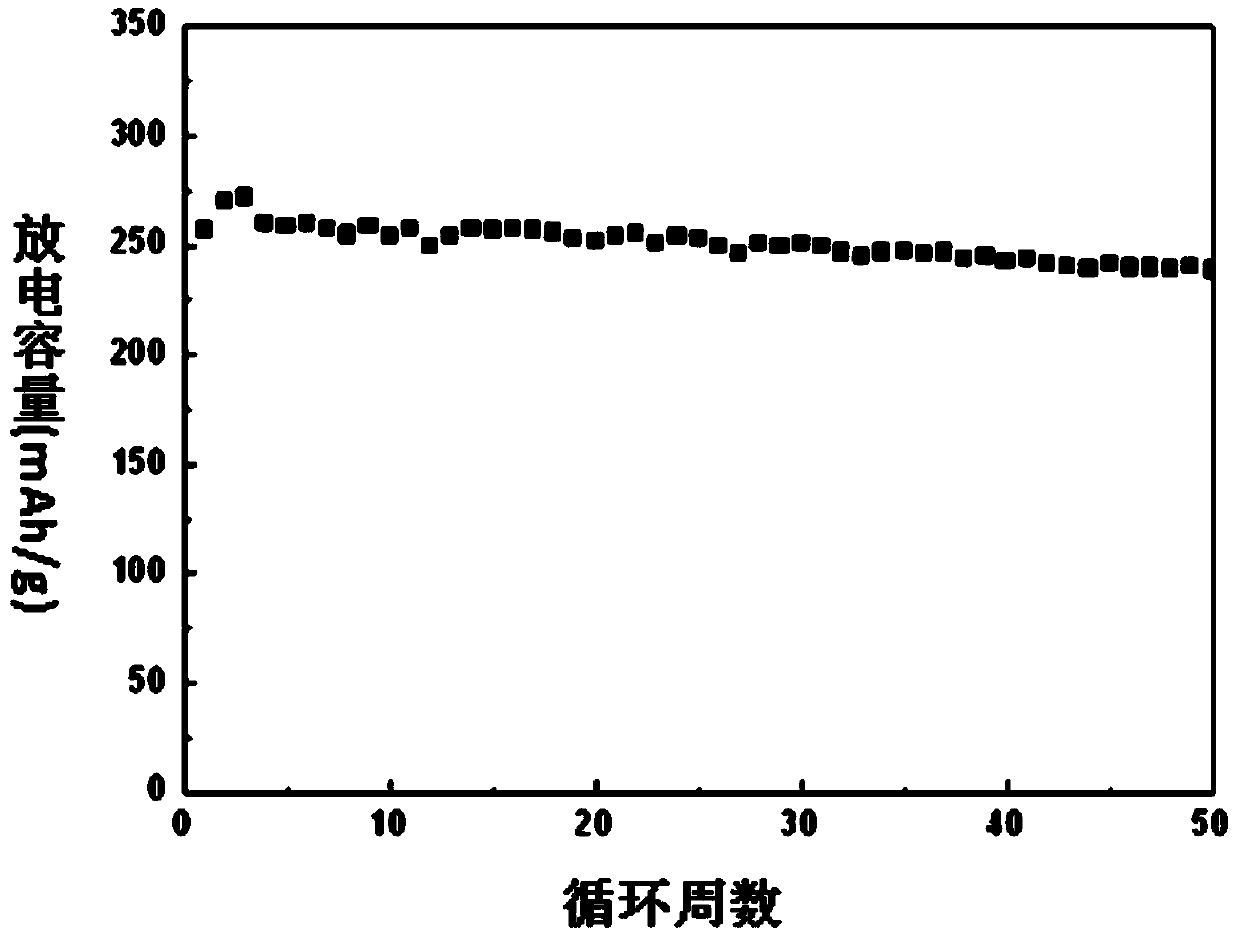

Preparation method of lithium-rich manganese-base anode material

A positive electrode material, lithium-rich manganese-based technology, applied in the field of preparation of lithium-rich manganese-based positive electrode materials, can solve the problems of difficult large-scale industrial preparation, small cation mixing degree, low production cost, etc., to achieve easy large-scale production, The effect of high electrochemical capacity and low capacity fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Ni(NO 3 ) 2 and Mn(NO 3 ) 2 According to the molar ratio Ni(NO 3 ) 2 : Mn(NO 3 ) 2 =0.300:0.567 ratio is dissolved in deionized water, configured as a solution with a transition metal ion concentration of 1mol / L, placed in the container of the ultrasonic spray equipment, and an excess NaOH solution with a concentration of 1mol / L is placed in the container. Adjust the ultrasonic spray equipment so that the transition metal ion solution enters the ultrasonic atomization device through the ultrasonic spray head at a flow rate of 50mL / min, start the ultrasonic power supply at the same time, adjust a certain ultrasonic power to 0.8MHz, and spray the atomized transition metal salt solution solution Into the precipitant solution, during the spraying process, the precipitant solution is stirred under the action of a high-speed stirrer. Stop stirring after the spraying is over, let the reaction product stand for 12 hours and then wash the precipitate film, dry and wash th...

Embodiment 2

[0027] Mn(CH 3 COO) 2 and Ni(CH 3 COO) 2 According to the molar ratio Mn(CH 3 COO) 2 :Ni(CH 3 COO) 2 Dissolve in deionized water at a ratio of =0.300:0.567, configure a solution with a transition metal ion concentration of 0.5mol / L, put it into the container of the ultrasonic spray equipment, and configure an excess KOH solution with a concentration of 1mol / L into the container. Adjust the ultrasonic spray equipment so that the transition metal ion solution enters the ultrasonic atomization device through the ultrasonic spray head at a flow rate of 100mL / min, start the ultrasonic power supply at the same time, adjust a certain ultrasonic power to 1MHz, and spray the atomized transition metal salt solution into the In the precipitant solution, during the spraying process, the precipitant solution is stirred under the action of a high-speed stirrer. Stop stirring after the spraying is over, let the reaction product stand for 12 hours and then wash the precipitate film, dr...

Embodiment 3

[0029] Ni(NO 3 ) 2 , Mn(NO 3 ) 2 and Co(NO 3 ) 2 According to the molar ratio Ni(NO 3 ) 2 : Mn(NO 3 ) 2 : Co(NO 3 ) 2 The ratio of =0.13:0.54:0.13 is dissolved in deionized water, configured as a solution with a transition metal ion concentration of 1mol / L, placed in the container of the ultrasonic spray equipment, and an excess KOH solution with a concentration of 2mol / L is placed in the container. Adjust the ultrasonic spray equipment so that the transition metal ion solution enters the ultrasonic atomization device through the ultrasonic spray head at a flow rate of 50mL / min, start the ultrasonic power supply at the same time, adjust a certain ultrasonic power to 0.8MHz, and spray the atomized transition metal salt solution solution Into the precipitant solution, during the spraying process, the precipitant solution is stirred under the action of a high-speed stirrer. Stop the stirring after the spraying is over, wash the precipitate film after the reaction produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com