Method for preparing bamboo charcoal/polyaniline composite material by adopting bamboo charcoal

A composite material, polyaniline technology, applied in the direction of hybrid capacitor electrodes, electrolytic capacitors, electrical components, etc., can solve the problems of volume expansion or shrinkage, uncertain performance of conductive polymers, etc., and achieve good thermal performance and high electrochemical capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

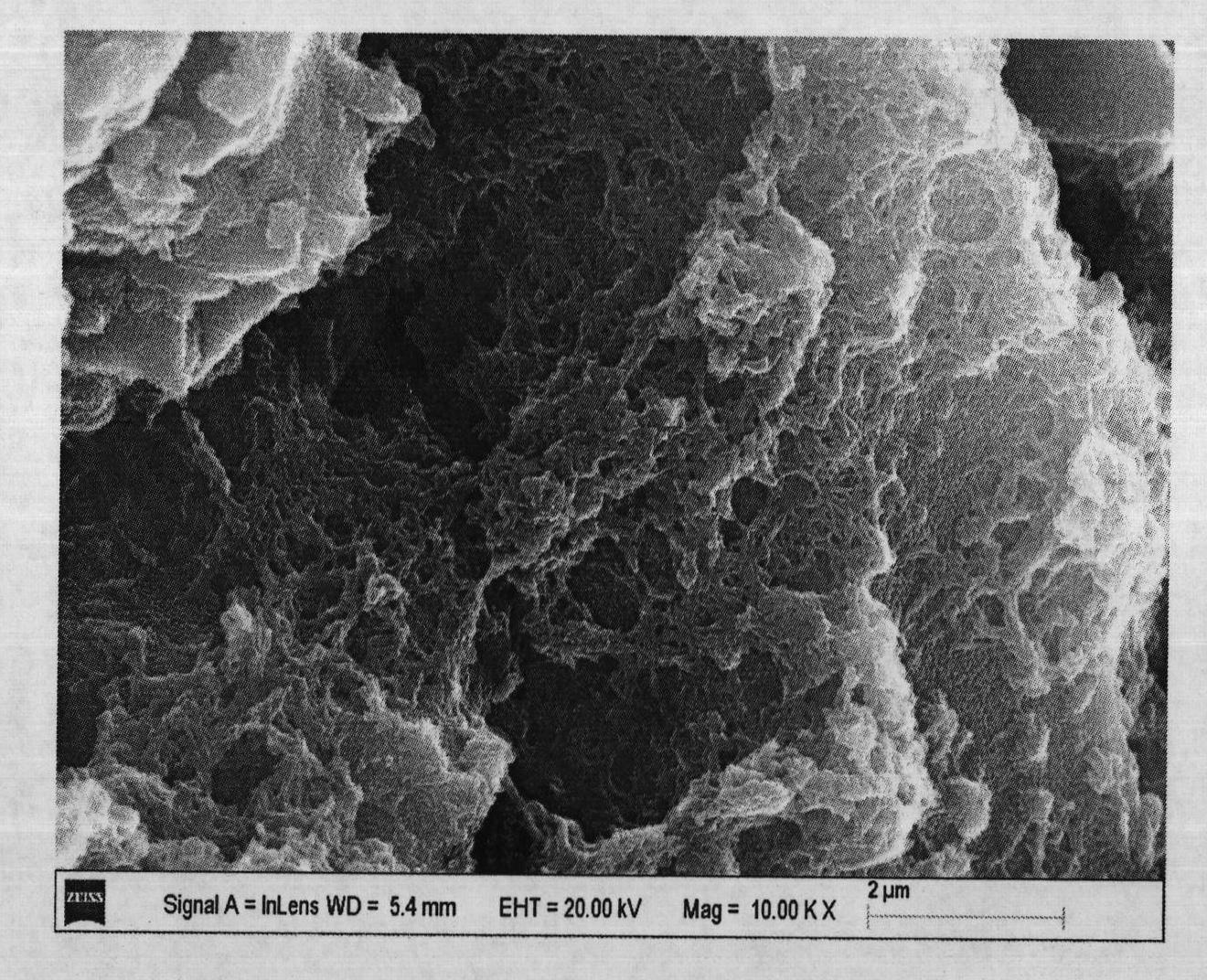

Image

Examples

Embodiment 1

[0020] (1) Measure 50mL of concentrated hydrochloric acid, weigh 3.48g of ammonium persulfate and dissolve it in an appropriate amount of water to make the volume of the whole system 300mL, that is, the concentration of hydrochloric acid is 2moL / L. After completely dissolving, pour it into a three-necked bottle, add 1.5g of bamboo charcoal, Stir for 15 minutes, so that the bamboo charcoal can be evenly dispersed in the system, and place the three-necked bottle under an ice bath.

[0021] (2) Get a small beaker, take by weighing the mixed solution of 1g aniline, 7g cyclohexane, 7g n-amyl alcohol in fume hood, the mass ratio of bamboo charcoal and aniline this moment is 3: 2, the mole of ammonium persulfate and aniline The ratio is 1.5:1, shake gently to mix the solution evenly, then pour it into a constant pressure dropping funnel, and control the titration speed so that it drops into a three-necked flask within 30 minutes. The temperature was controlled at 0°C, and the dynamic...

Embodiment 2

[0025] The operation method is the same as Example 1, except that the acid consumption is 25mL, that is, the system acid concentration is 1moL / L; the bamboo charcoal quality is 4g, and the mass ratio of bamboo charcoal and monomer aniline is 4: 1; the ammonium persulfate consumption is 2.32 g, the molar ratio of ammonium persulfate and aniline is 1.5:1.

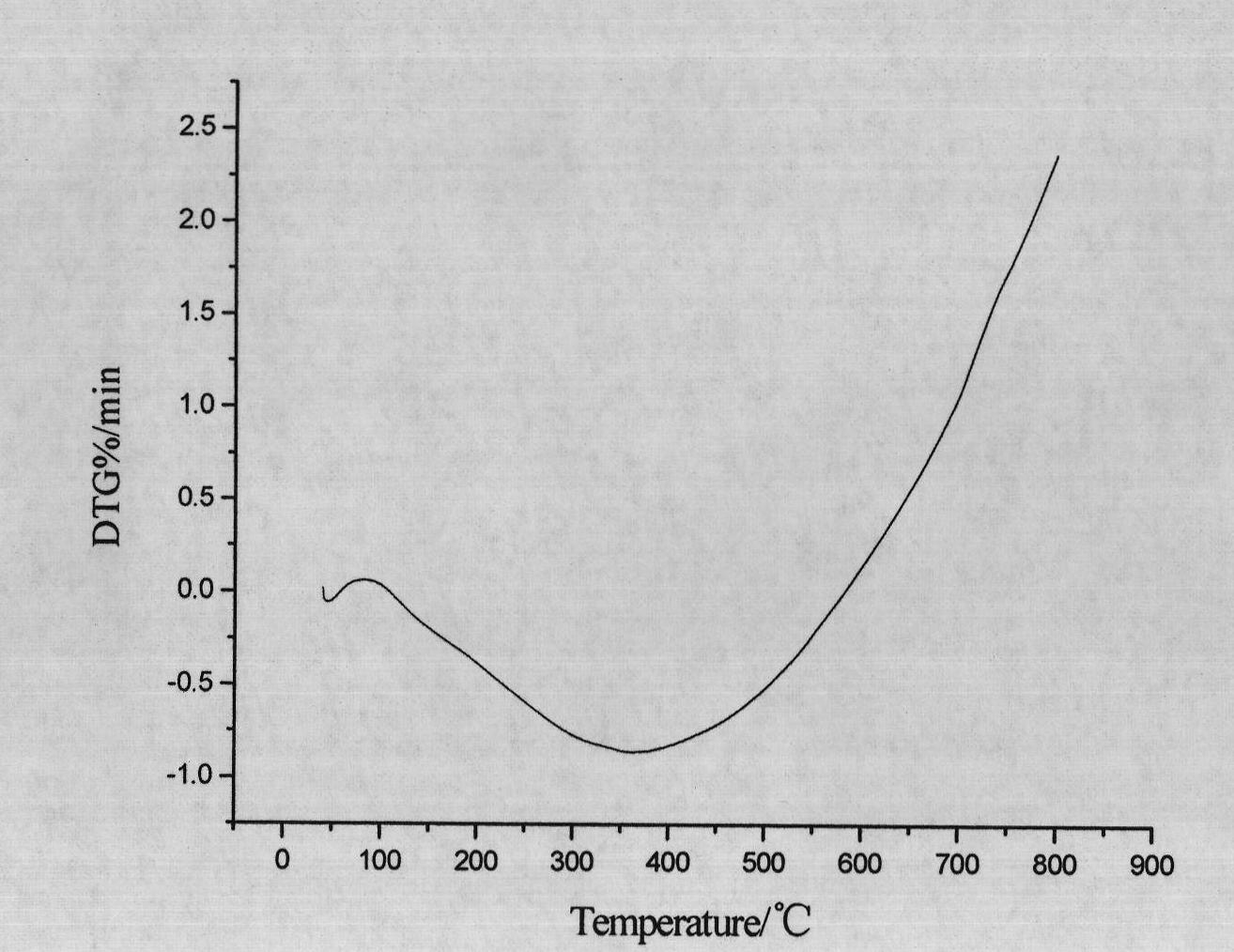

[0026] Depend on figure 2 It can be seen from the DSC curve that there is a relatively obvious exothermic peak around 360°C, which is the temperature at which polyaniline in the composite material begins to decompose. It can be seen that the thermal performance of the composite material is excellent.

Embodiment 3

[0028] The operation method is the same as in Example 1, except that the acid consumption is 25mL, that is, the system acid concentration is 1moL / L, and the ammonium persulfate consumption is 2.32g, that is, the molar ratio of ammonium persulfate and aniline is 1:1.

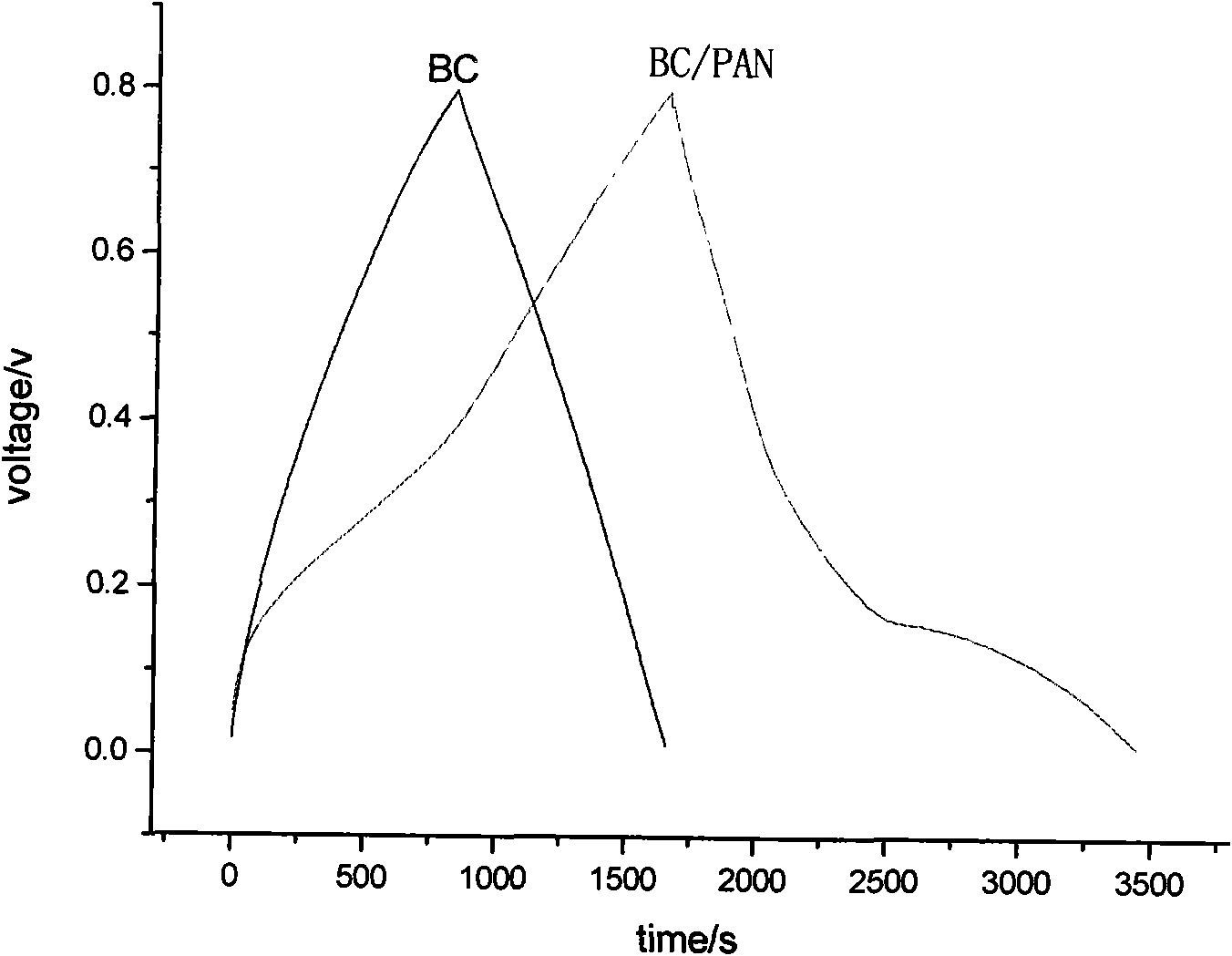

[0029] Depend on image 3 It can be seen from the charge-discharge curve of the bamboo charcoal that the curve is a relatively symmetrical triangle, which belongs to an electric double layer capacitor. From the charge-discharge curve of the composite material, it can be seen that there is a pseudocapacitance, and the charge-discharge time of the composite material is two times that of bamboo charcoal. times, that is, its capacitance is much higher than that of the original bamboo charcoal material, indicating that the composite material has greater advantages than the single material in terms of electrochemical performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com