A metal-doped manganese carbonate electrode material based on carbon cloth growth and its preparation method and application

A metal doping, electrode material technology, applied in nanotechnology for materials and surface science, battery electrodes, circuits, etc., can solve the problems of low cycle performance preparation technology, achieve high cycle stability, reduce the required time , the effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

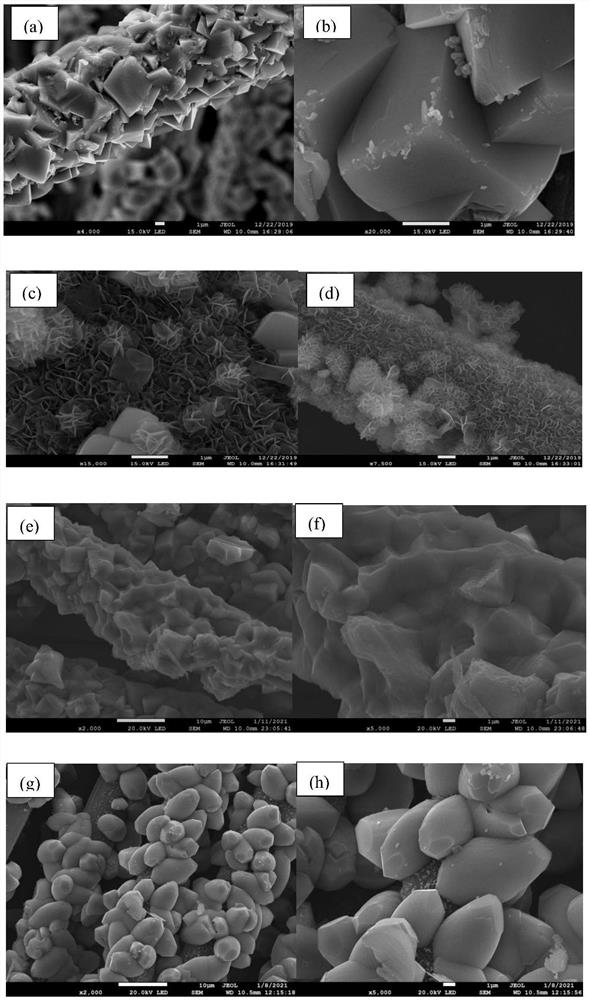

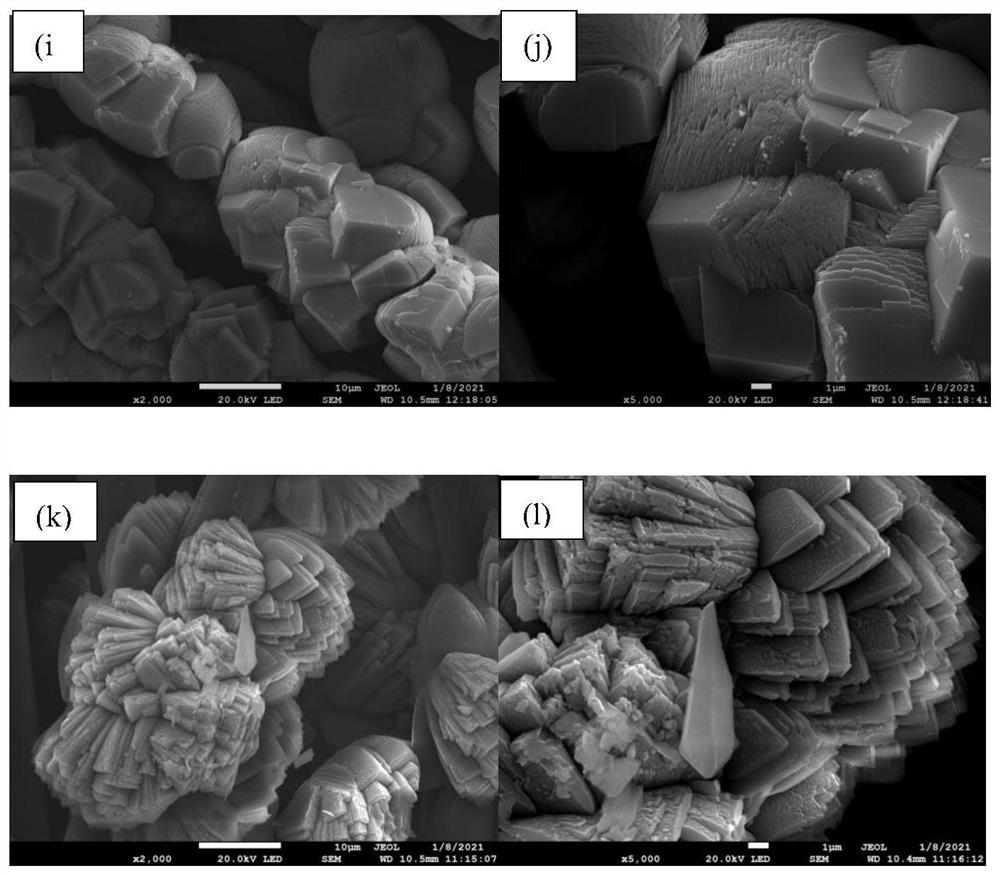

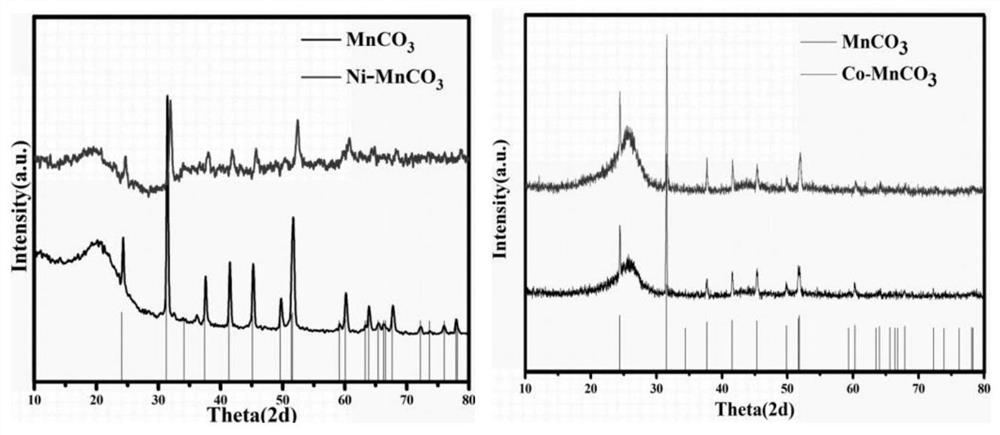

Embodiment 1

[0048] A kind of pure manganese carbonate (MnCO 3 / CC) preparation method of electrode material, the steps are as follows:

[0049] (a) At room temperature, cut a 3*2cm empty carbon cloth and put it into an empty beaker, add concentrated nitric acid with a concentration of 8mol / L, and place the beaker in a water bath for 2 hours at a constant temperature of 70°C. ; After soaking, clean the carbon cloth alternately with deionized water and absolute ethanol for 5 to 6 times, put it in a drying box after cleaning, and dry it at 60°C for 12 hours, for later use;

[0050] (b) in another beaker, add 10mmoL manganese acetate, 50mmoL urea and 40mL deionized water, after the configuration, the resulting mixture is put into a magnetic stirrer and stirred, until the solid is completely dissolved to obtain a mixed solution;

[0051] (c) put the mixed solution obtained in step (b) into the inner liner of the 100mL reaction kettle; after cleaning the polytetrafluoroethylene plate with abso...

Embodiment 2

[0054] A kind of nickel-doped manganese carbonate (Ni-MnCO) based on carbon cloth growth in this embodiment 3 / CC) preparation method of electrode material, the steps are as follows:

[0055] (a) At room temperature, cut a 3*2cm empty carbon cloth and put it into an empty beaker, add concentrated nitric acid with a concentration of 8mol / L, and place the beaker in a water bath for 2 hours at a constant temperature of 70°C. ; After soaking, clean the carbon cloth alternately with deionized water and absolute ethanol for 5 to 6 times, put it in a drying box after cleaning, and dry it at 60°C for 12 hours, for later use;

[0056] (b) in another beaker, add 2mmoL manganese acetate, 8mmoL nickel acetate, 50mmoL urea and 40mL deionized water, after configuring, the resulting mixture is put into a magnetic stirrer and stirred, until the solid is completely dissolved to obtain a mixed solution;

[0057] (c) put the mixed solution obtained in step (b) into the inner tank of the 100mL r...

Embodiment 3

[0060] A kind of cobalt-doped manganese carbonate (Co-MnCO) grown based on carbon cloth in this embodiment 3 / CC) preparation method of electrode material, the steps are as follows:

[0061] (a) At room temperature, cut a 3*2cm empty carbon cloth and put it into an empty beaker, add concentrated nitric acid with a concentration of 8mol / L, and place the beaker in a water bath for 2 hours at a constant temperature of 70°C. ; After soaking, clean the carbon cloth alternately with deionized water and absolute ethanol for 5 to 6 times, put it in a drying box after cleaning, and dry it at 60°C for 12 hours, for later use;

[0062] (b) in another beaker, add 9mmoL manganese acetate, 1mmoL cobalt acetate, 50mmoL urea and 40mL deionized water, after configuring, the resulting mixture is put into a magnetic stirrer and stirred, until the solid is completely dissolved, to obtain a mixed solution;

[0063] (c) put the mixed solution obtained in step (b) into the inner tank of the 100mL r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com