High charge-discharge magnification lithium iron phosphate material used for anode of lithium ion battery and its preparation method

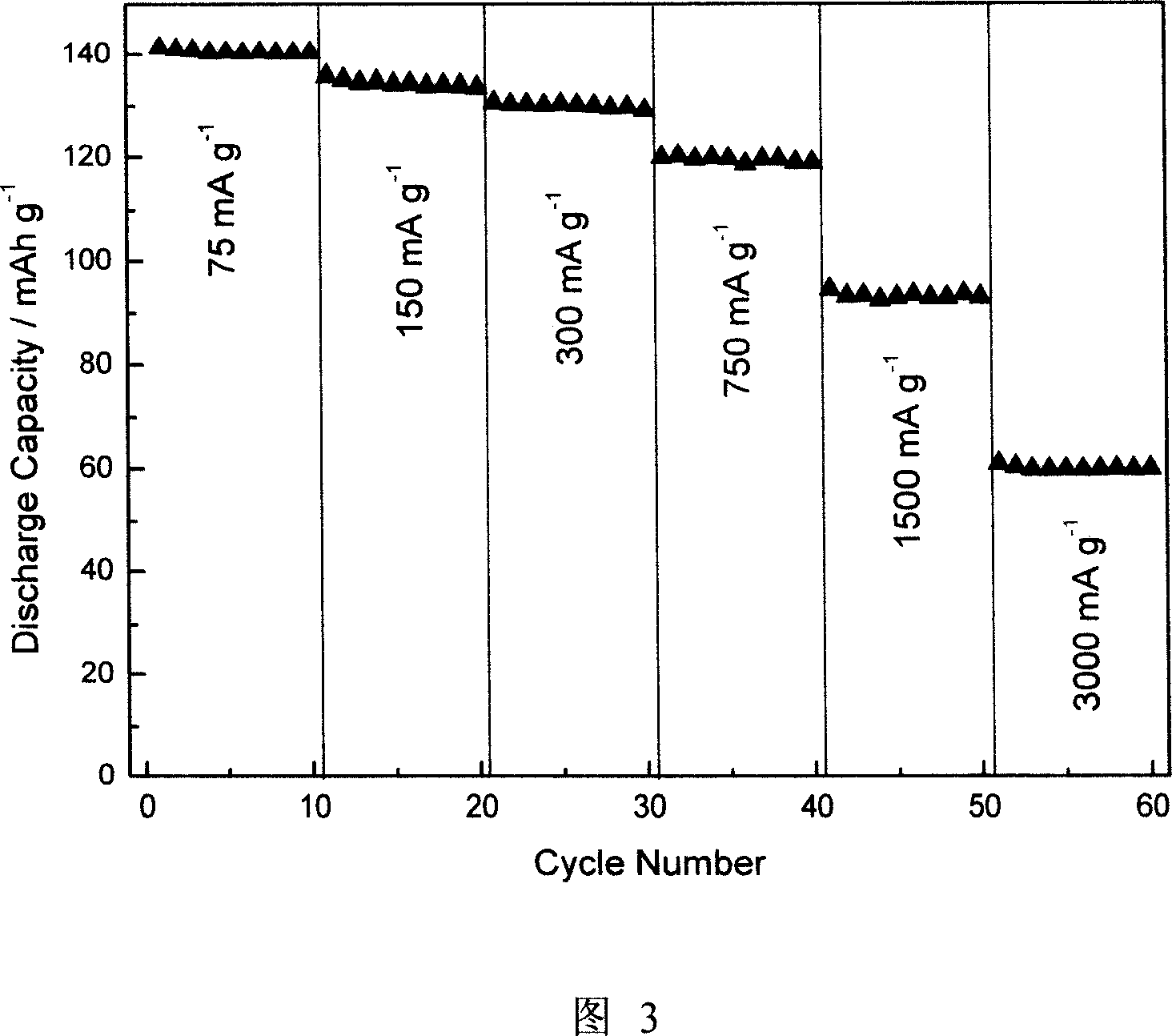

A lithium-ion battery, charge-discharge rate technology, applied in electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve problems such as the performance impact of lithium iron phosphate, and achieve strong high-rate charge-discharge capacity, high specific capacity, good Effects of Cyclic Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Hereby further understand content and advantage of the present invention with following embodiment:

[0022] Weigh FeC 2 o 4 2H 2 O 17.99g, LiOH·H 2 O 4.196g, (NH 4 ) 2 HPO 4 13.21 g, PEG (M=5000) 5 g. Disperse the above raw materials with 200mL deionized water as a suspension, add citric acid (C 7 h 8 o 7 ·H 2 O) 42.02g. Continue stirring until a gel forms. The resulting gel was pulverized by an agate ball mill and put into a porcelain crucible. at a velocity of 1dm 3 min -1 99.999% argon flow, at 3°C·min -1 The temperature was raised to 300°C at the same rate and kept for 3 hours, and the temperature was raised to 700°C at the same rate and kept for 8 hours. Naturally cool to room temperature with the furnace, take out the product and grind to obtain the lithium iron phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com