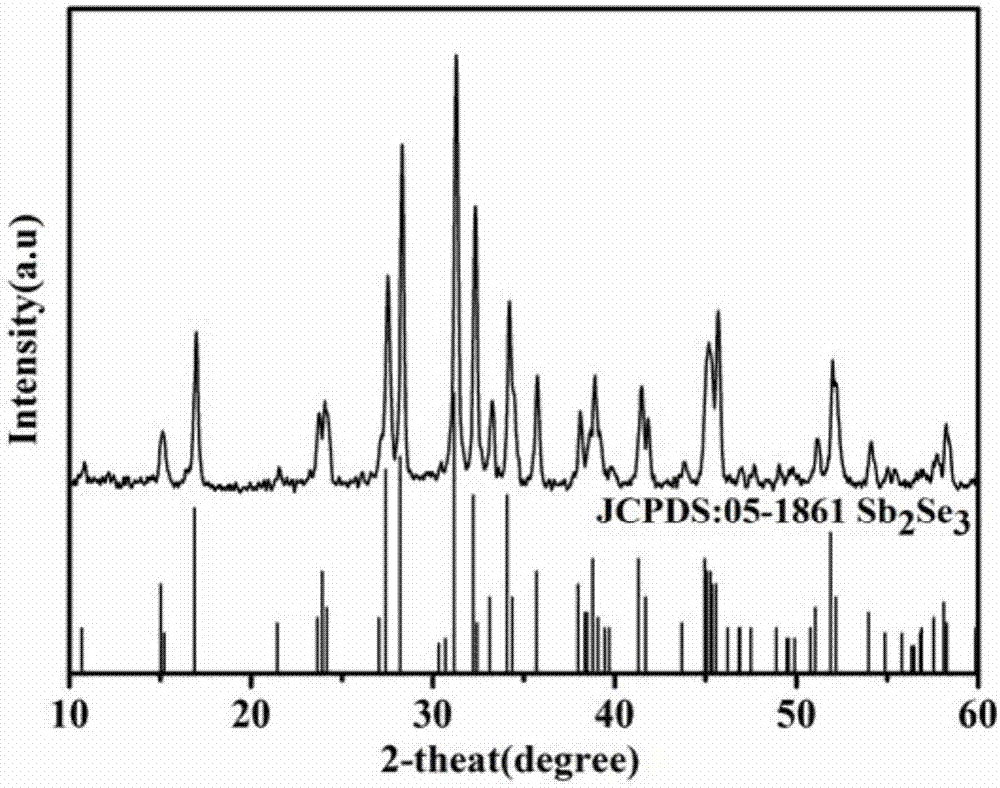

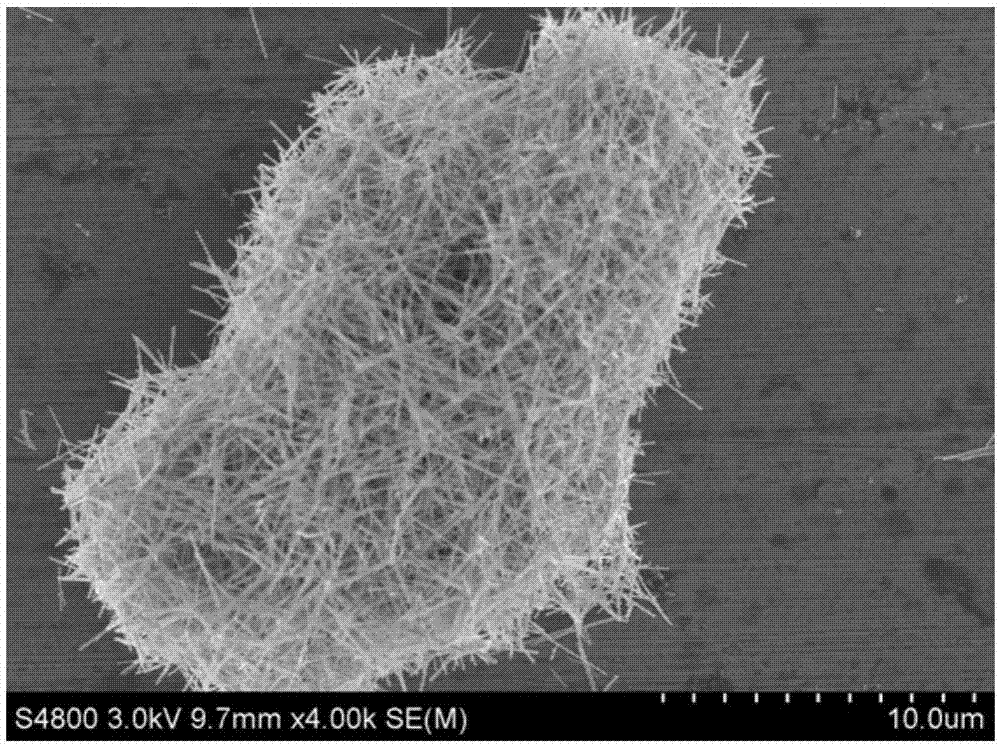

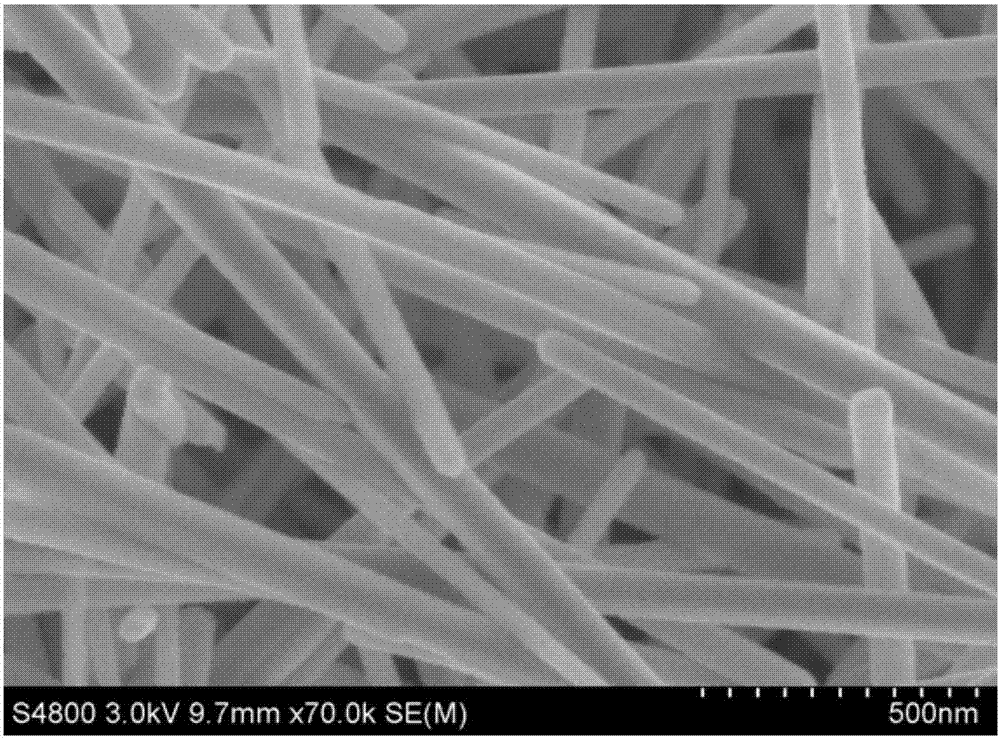

Method for preparing ultra-dispersed antimony selenide nanowires for sodium-ion battery negative electrodes with ultrasonic-assisted hydrothermal method

A sodium-ion battery, antimony selenide nanotechnology, applied in battery electrodes, nanotechnology for materials and surface science, negative electrodes, etc. Simple, high electrochemical capacity, high raw material utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Add β-cyclodextrin to 20mL distilled water, and ultrasonically shake (300W, 40°C, 20min) to completely dissolve and disperse evenly to obtain solution A. Control the concentration of β-cyclodextrin to 0.565×10 -2 mol / L;

[0030] 2) Add 0.112g of tartaric acid and 0.0675g of antimony potassium tartrate into 30mL of distilled water, stir (500r / min, 20min) until completely dissolved, and obtain solution B;

[0031] 3) Disperse 0.0236g of selenium powder in 3mL of hydrazine hydrate with a mass concentration of 50%, and ultrasonically oscillate (300W, 50°C, 20min) to completely dissolve it to obtain wine red solution C;

[0032] 4) The obtained solution B was added dropwise to the solution A under the condition of stirring (500r / min) to obtain the mixed solution D;

[0033] 5) First, under the condition of stirring (500r / min), add the obtained wine red solution C dropwise into the mixed solution D, and stir evenly to obtain the mixed solution E; then, transfer the mixed ...

Embodiment 2

[0035] 1) Add β-cyclodextrin into 25mL of distilled water, and ultrasonically shake (600W, 70°C, 60min) to completely dissolve and disperse evenly to obtain solution A. Control the concentration of β-cyclodextrin to 1.13×10 -2 mol / L;

[0036] 2) Add 0.3g of tartaric acid and 0.6759g of antimony potassium tartrate into 25mL of distilled water, stir (700r / min, 60min) until completely dissolved, and obtain solution B;

[0037] 3) Disperse 0.2369g of selenium powder in 5mL of hydrazine hydrate with a mass concentration of 50%, and ultrasonically oscillate (600W, 70°C, 60min) to completely dissolve it to obtain wine red solution C;

[0038] 4) Add the obtained solution B to the solution A dropwise under stirring (700r / min) to obtain the mixed solution D;

[0039] 5) First, under the condition of stirring (700r / min), add the obtained wine red solution C dropwise into the mixed solution D, and stir evenly to obtain the mixed solution E; then, transfer the mixed solution E to a polyt...

Embodiment 3

[0043] 1) Add β-cyclodextrin to 20mL distilled water, and ultrasonically shake (200W, 40°C, 10min) to completely dissolve and disperse evenly to obtain solution A. Control the concentration of β-cyclodextrin to 1.695×10 -2 mol / L;

[0044] 2) Add 0.03g of tartaric acid and 0.0337g of antimony potassium tartrate into 40mL of distilled water, stir (500r / min, 10min) until completely dissolved, and obtain solution B;

[0045] 3) Disperse 0.0118g of selenium powder in 2mL of hydrazine hydrate with a mass concentration of 50%, and ultrasonically oscillate (200W, 40°C, 10min) to completely dissolve it to obtain wine red solution C;

[0046] 4) The obtained solution B was added dropwise to the solution A under the condition of stirring (500r / min) to obtain the mixed solution D;

[0047] 5) First, under the condition of stirring (500r / min), add the obtained wine red solution C dropwise into the mixed solution D, and stir evenly to obtain the mixed solution E; then, transfer the mixed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com