Carbon contact strip of pantograph and manufacturing method thereof

A pantograph carbon sliding plate and a manufacturing method technology, which are applied in the field of electric locomotives, can solve the problems of non-wearability of metal sliding plates, difficult to guarantee the overall quality, and high resistance of carbon sliding plates, and achieve good arc resistance, good impact toughness, and self-resistance. Good lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

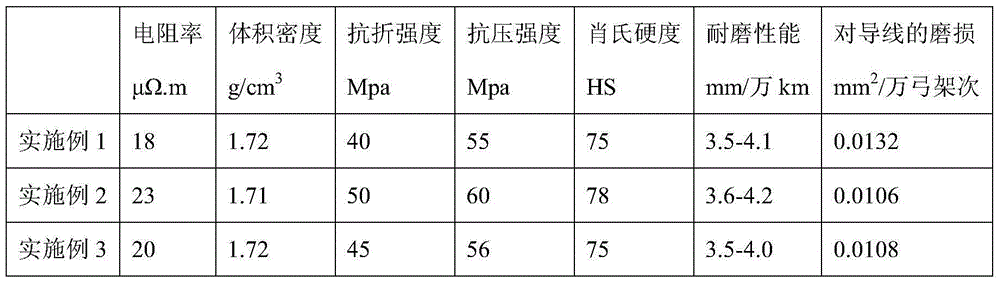

Examples

Embodiment 1

[0056] 1) Prepare raw materials according to the following weight ratio:

[0057] Petroleum coke powder 43, pitch coke powder 25, spray carbon black 10, sulfur 2, boron nitride 3, carbon fiber 5, natural graphite 5, artificial graphite 6, calcium chloride powder 1, modified pitch 30

[0058] Among them, the particle size of petroleum coke powder and pitch coke powder is 100 mesh; both sulfur and boron nitride are hexagonal, with a purity of 99%; the length of carbon fiber is 5 mm; the particle size of natural graphite and artificial graphite is 75 μm; calcium chloride powder The particle size is 200 mesh.

[0059] Among them, sulfur can increase the lubricity and mechanical strength of carbon skateboards; boron nitride can suppress sparks; carbon fiber can enhance mechanical strength, natural graphite can increase the lubricity of carbon skateboards, artificial graphite can increase the wear resistance of carbon skateboards; calcium chloride Increase wear resistance.

[0060...

Embodiment 2

[0077] 1) Prepare raw materials according to the following weight ratio:

[0078] Petroleum coke powder 28, pitch coke powder 28, spray carbon black 12, sulfur 5, boron nitride 5, carbon fiber 8, natural graphite 5, artificial graphite 6, calcium chloride powder 3, modified pitch 35

[0079] Among them, the particle size of petroleum coke powder and pitch coke powder is 100 mesh; both sulfur and boron nitride are hexagonal, with a purity of 99%; the length of carbon fiber is 10 mm; the particle size of natural graphite and artificial graphite is 75 μm; calcium chloride powder The particle size is 300 mesh.

[0080] Add petroleum coke powder, pitch coke powder, spray carbon black, sulfur, boron nitride, carbon fiber, natural graphite, artificial graphite, and calcium chloride powder into a Z-type mixer for stirring to obtain a mixed dry powder. The stirring temperature is 130 ℃, stirring time is 40min.;

[0081] 2) Naturally cool the mixed dry powder to 120°C, add melted modi...

Embodiment 3

[0097] 1) Prepare raw materials according to the following weight ratio:

[0098] Petroleum coke powder 36, pitch coke powder 26, spray carbon black 11, sulfur 4, boron nitride 4, carbon fiber 6, natural graphite 5, artificial graphite 6, calcium chloride powder 2, modified pitch 32

[0099] Among them, the particle size of petroleum coke powder and pitch coke powder is 100 mesh; both sulfur and boron nitride are hexagonal, with a purity of 99%; the length of carbon fiber is 5-10 mm; the particle size of natural graphite and artificial graphite is 75 μm; The particle size of the calcium powder is 250 mesh.

[0100] Add petroleum coke powder, pitch coke powder, spray carbon black, sulfur, boron nitride, carbon fiber, natural graphite, artificial graphite, and calcium chloride powder into a Z-type mixer for stirring to obtain a mixed dry powder. The stirring temperature is 110 ℃, stirring time is 50min.;

[0101] 2) Naturally cool the mixed dry powder to 100°C, add melted modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com