Modified natural graphite material used in lithium ion battery negative electrodes, and preparation method thereof

A lithium-ion battery and natural graphite technology, which is applied in the field of modified natural graphite negative electrode materials for lithium-ion batteries and its preparation, can solve the problems of poor cycle performance, low initial efficiency, large irreversible capacity, etc., and achieves good rate performance and initial efficiency. High, improve the effect of first-time efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

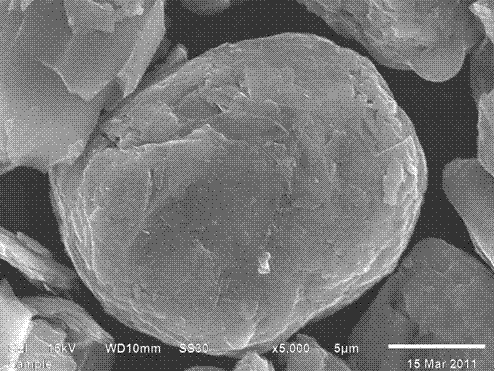

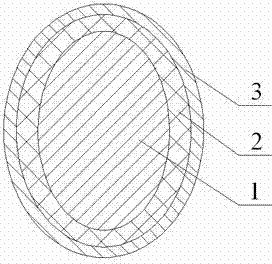

[0023] A modified natural graphite negative electrode material for lithium ion batteries, having a core-shell structure, comprising an inner core and a shell coated on the outside of the core, the core is natural graphite, and the shell coated on the outside of the core is composed of an inner shell and an outer shell. The inner shell is a boron-containing hard carbon layer, and the outer shell is a soft carbon layer, such as figure 2 As shown, the natural graphite 1 is covered with a boron-containing hard carbon layer 2, and the boron-containing hard carbon layer 2 is covered with a soft carbon layer 3, and the natural graphite is a fixed carbon content of ≥99.0%, D50 particle size It is 8-25 micron-like spherical natural graphite, the quality of the boron-containing hard carbon layer is 4.8% of the quality of the natural graphite, and the quality of the soft carbon layer is 4.5% of the quality of the natural graphite.

[0024] A preparation method of a lithium-ion battery m...

Embodiment 2

[0028] The amount of phenolic resin in Example 1 was changed to 160 g, and other conditions remained unchanged.

[0029] The detection method is the same as in Example 1, and the test results are listed in Table 1.

Embodiment 3

[0031] The amount of boric acid in Example 1 was changed to 15 g, and other conditions remained unchanged.

[0032] The detection method is the same as in Example 1, and the test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com