Red fluorescent powder used by white light LED and preparation method thereof

A technology of red fluorescent and fluorescent powder, which is applied in chemical instruments and methods, luminescent materials, and the use of gas discharge lamps. It can solve the problems of insufficient stability and easy decomposition, and achieve the effect of easy operation, simple steps and conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

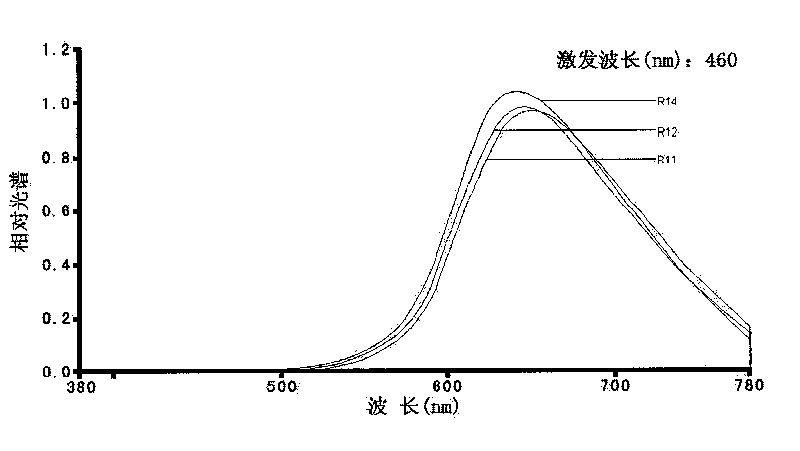

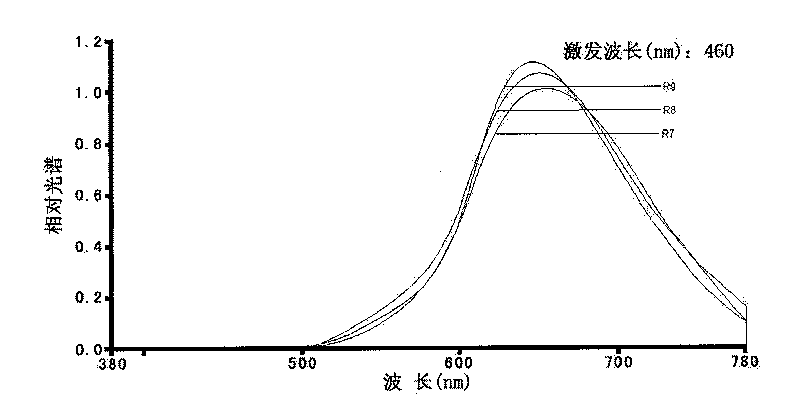

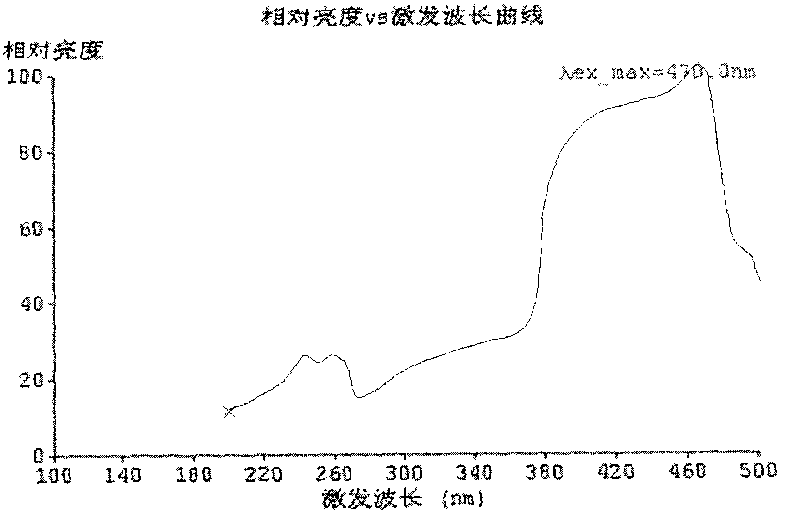

Image

Examples

example 1

[0025] Accurately weigh raw material Sr 3 N 2 36.26g, Si 3 N 4 46.75g, Li 3 N 0.12g, YF 3 1.46g, Eu 2 o 3 1.06g, pre-mix the above raw materials, then add YF 3 1.46g is used as a flux, put into a ball milling tank for ball milling and mixing, the ball milling time is 2-5h, the ball milling tank is sealed, and filled with nitrogen as a protective gas. After completion, put the uniformly mixed materials into an alumina crucible and put them in a tubular resistance furnace for calcination, keep warm at 1580°C for 4 hours, the heating rate is about 5°C / min, and naturally cool to room temperature after the heat preservation, the whole calcination process is complete Access to NH 3 gas as a protective and nitriding gas. After cooling, take out the bulk powder, mechanically crush it, and then ball mill until the average particle size reaches 6.0±0.5um, and pass through 0.1mol / L HNO 3 Pickling, soaking in 80□C hot water to remove impurities, and then centrifugal drying ...

example 2

[0027] Accurately weigh raw material Sr 3 N 2 35.87g, Si 3 N 4 46.75g, Li 3 N 0.12g, YF 3 1.46g, Eu2 o 3 1.76g, pre-mix the above raw materials, then add YF 3 1.46g is used as a flux, put into a ball milling tank for ball milling and mixing, the ball milling time is 2-5h, the ball milling tank is sealed, and filled with nitrogen as a protective gas. After completion, put the uniformly mixed materials into an alumina crucible and put them in a tubular resistance furnace for calcination, keep warm at 1580°C for 4 hours, the heating rate is about 5°C / min, and naturally cool to room temperature after the heat preservation, the whole calcination process is complete Access to NH 3 gas as a protective and nitriding gas. After cooling, take out the bulk powder, mechanically crush it, and then ball mill until the average particle size reaches 6.0±0.5um, and pass through 0.1mol / L HNO 3 Pickling, soaking in 80□ hot water to remove impurities, and then centrifugal drying to ...

example 3

[0029] Accurately weigh raw material Sr 3 N 2 36.26g, Si 3 N 4 45.82g, AlN 0.82g, Li 3 N 0.12g, YF 3 1.46g, Eu 2 o 3 1.06g, pre-mix the above raw materials, then add YF 3 1.46g is used as a flux, put into a ball milling tank for ball milling and mixing, the ball milling time is 2-5h, the ball milling tank is sealed, and filled with nitrogen as a protective gas. After completion, put the uniformly mixed materials into an alumina crucible and put them in a tubular resistance furnace for calcination, keep warm at 1580°C for 4 hours, the heating rate is about 5°C / min, and naturally cool to room temperature after the heat preservation, the whole calcination process is complete Access to NH 3 gas as a protective and nitriding gas. After cooling, take out the bulk powder, mechanically crush it, and then ball mill until the average particle size reaches 6.0±0.5um, and pass through 0.1mol / L HNO 3 Pickling, soaking in 80□C hot water to remove impurities, and then centrifu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com