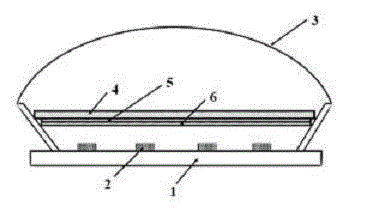

Remote phosphor structure applicable to LED lighting and production method thereof

A remote phosphor and LED lighting technology, applied in the field of phosphor, can solve the problems of high color rendering and low color temperature at the same time, and achieve the effects of ensuring luminous efficiency, reducing color temperature, and ensuring uniformity of brightness and chromaticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

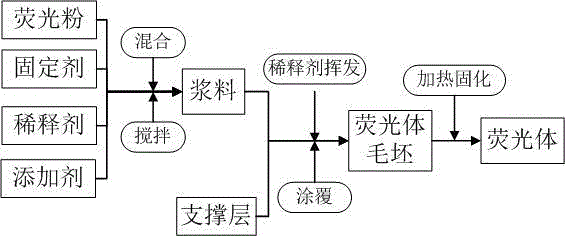

[0044]Mix blue, green and red phosphors with silica gel respectively, add xylene as a diluent, and stir evenly to obtain blue, green and red phosphor slurries respectively. Prepare the blue fluorescent layer on the PC board by scraping and masking. After drying at 100 degrees for 2 hours, scrape a layer of green fluorescent layer, and then dry at 100 degrees for 2 hours. Then scrape-coat a layer of red fluorescent layer, and dry it at 100 degrees for 2 hours to obtain a phosphor with blue-green-red superimposed fluorescent layer.

Embodiment 2

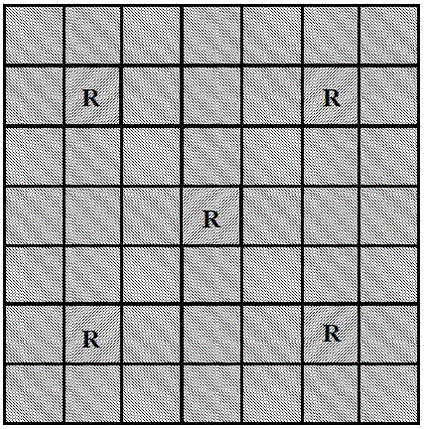

[0046] Mix yellow and red phosphors with epoxy resin respectively, add acetone as diluent and polyamine as curing agent and stir evenly to obtain yellow and red phosphor slurries respectively. Heat the PMMA plate to 80 degrees, use the method of spraying and masking in the pre-designed R area (such as figure 2 ) to prepare a red fluorescent layer, after drying at 100°C for 1 hour, replace the mask, spray a yellow fluorescent layer on the remaining area, and dry at 100°C for 1 hour, and finally obtain a yellow-red phosphor array of phosphors.

[0047] In the field of LED lighting applications, the multi-wavelength layered superposition or multi-wavelength array phosphor structure of the present invention is used as the light conversion element of LED lighting to realize the multi-spectrum emission of LED lighting, and can control the thickness of the phosphor layer , the area and shape of the phosphor array, etc., while improving the color rendering and reducing the color tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com