LED filament bulb

A technology of LED light bulbs and LED light strips, which is applied in cooling/heating devices of lighting devices, lighting and heating equipment, and semiconductor devices of light-emitting elements, etc. problem, to achieve the effect of solving poor heat dissipation and ensuring luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

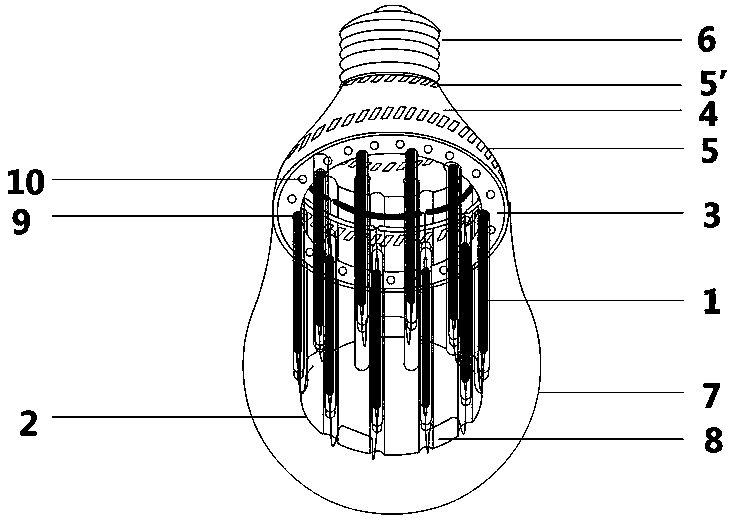

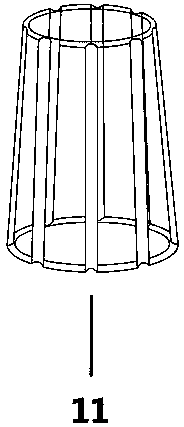

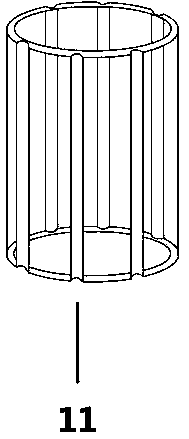

[0031] Embodiment 1: as figure 1 As shown, it is a schematic diagram of the implementation of a filament LED bulb in which a tube-shaped primitive LED is installed on a transparent tube with a semicircular groove. The transparent tube is made of quartz glass tube, hereinafter referred to as the quartz transparent tube. A filament LED light bulb comprises a lamp base 6, a plastic lamp base 4 and a glass bulb shell 7, the lamp base 6 is fixed on the upper end of the plastic lamp base 4, the glass bulb shell 7 is installed on the lower end of the plastic lamp base 4, and the driving power is built in the lamp base 6. The LED light-emitting element is a tube-shaped base unit LED1, and the outer diameter of the tube-shaped base unit LED1 is 3.2 mm and the length is 53 mm. and open like figure 2 , 3 , 4 and 5 shown in the quartz transparent tube 2 of the semicircular groove 11, the outer diameter of the quartz transparent tube 2 is 25mm, the wall thickness is 2.0mm, and the leng...

Embodiment 2

[0035] Embodiment 2: as Image 6 As shown, a filament LED light bulb uses a COB-packaged LED light bar as the LED light-emitting element. The outer diameter of the LED light bar is 2.2mm and the length is 45mm. The light bulb includes a lamp cap, an aluminum alloy lamp holder 12 is fixed under the lamp cap, the lower end of the aluminum alloy lamp holder 12 is connected with a bulb shell, and the bulb shell is filled with neon gas at half an atmospheric pressure, and the transparent tube is arranged in the bulb shell. Its upper part is close to the inner wall of the aluminum alloy lamp holder 12, and the edge can be bonded by glue. The wall thickness of the transparent tube is 3.5mm, the length is 75mm, and the insertion depth is about 25mm. There are 12 semicircular grooves with a diameter of 2.25mm on the transparent tube under the metal lamp holder. 12 LED light strips are pasted in the semicircular groove with transparent silicone. The 12 LED light bars are connected in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com