Radiator of LED (light emitting diode)

A light-emitting diode and heat sink technology, applied in the field of light-emitting diode heat sinks, can solve problems such as the decline in heat sink efficiency, the accumulation of dust on the back, and the hindrance of heat exchange between the heat sink and air, so as to improve heat dissipation efficiency and ensure luminous efficiency and normal lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

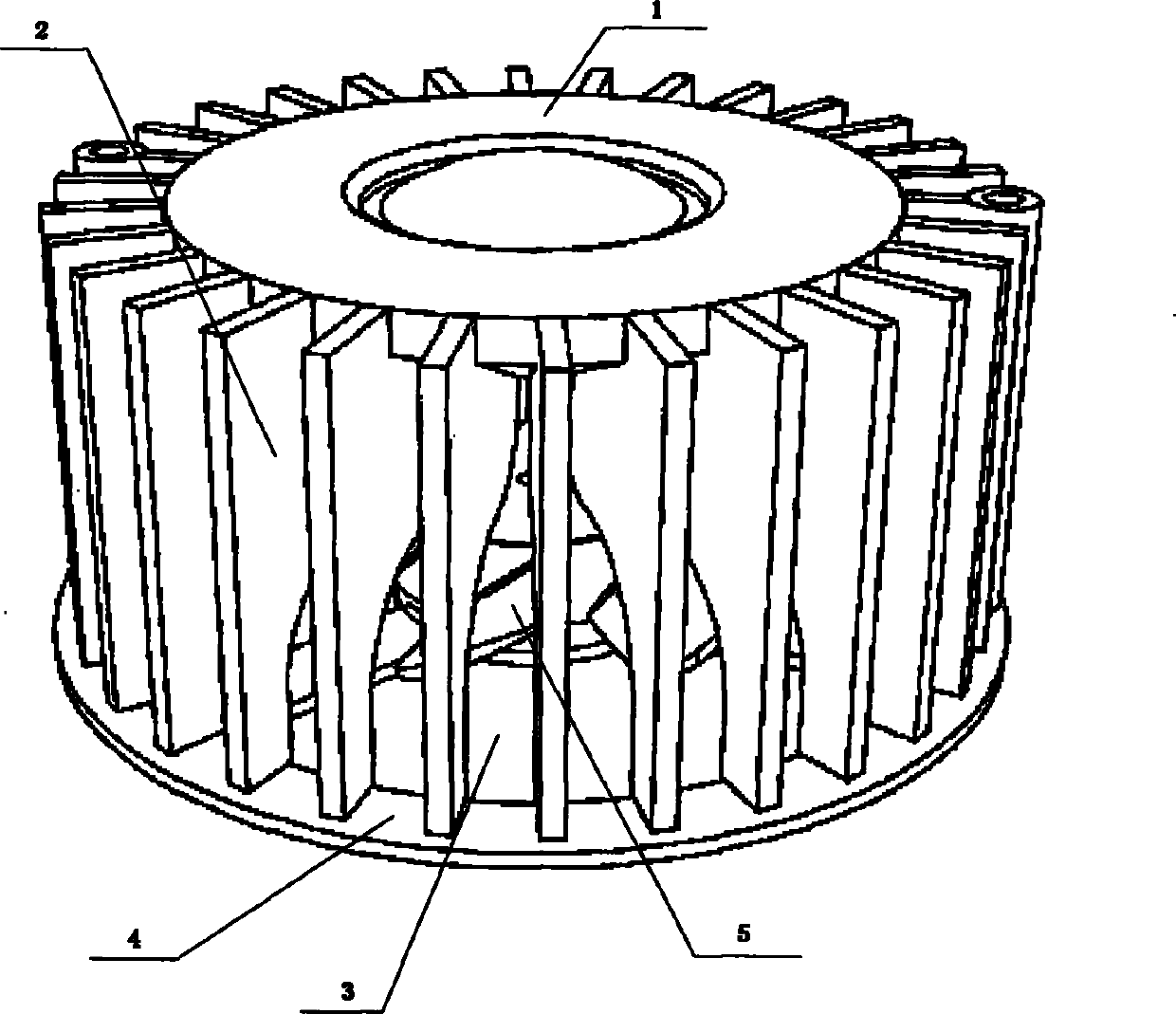

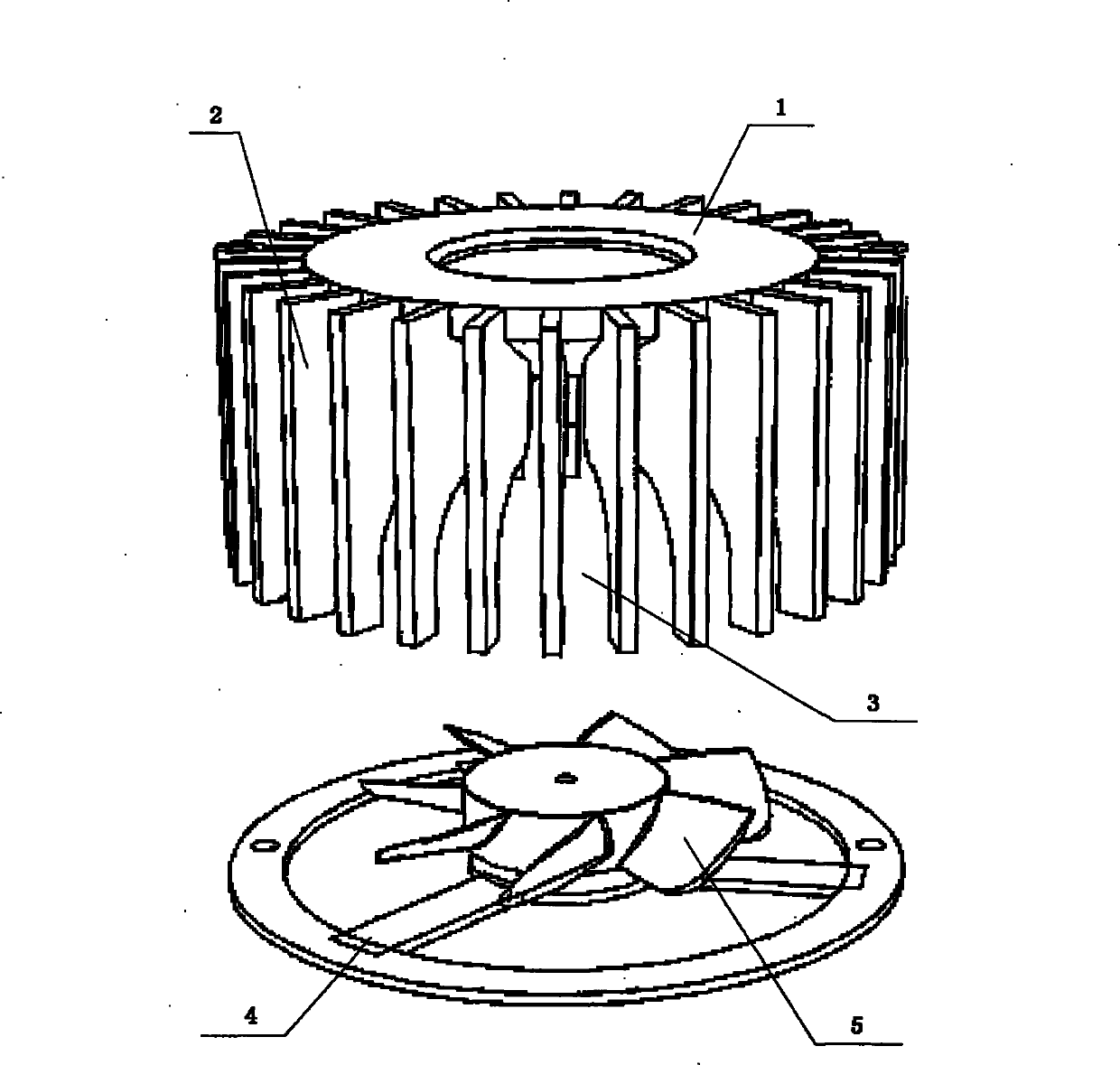

[0013] An LED light-emitting diode radiator, including a heat sink 1 and fins 2, the heat sink 1 is a hollow cylinder structure, the fins 2 are arranged longitudinally along the heat sink 1 cylinder, and the heat sink 1 It is structurally integrated with the fin 2, the length of the fin 2 is greater than the height of the cylinder of the heat sink 1, the side of the fin 2 away from the heat sink 1 is a straight line, and the other side has a slanted line, The slanted side of the fin 2 forms an open hollow portion 3, and the fin 2 is exposed on the end surface of the heat sink 1 and is also provided with a cooling fan 4, and the fan blade 5 of the cooling fan 4 is provided with In the hollow 3 formed by the fin 2 .

Embodiment 2

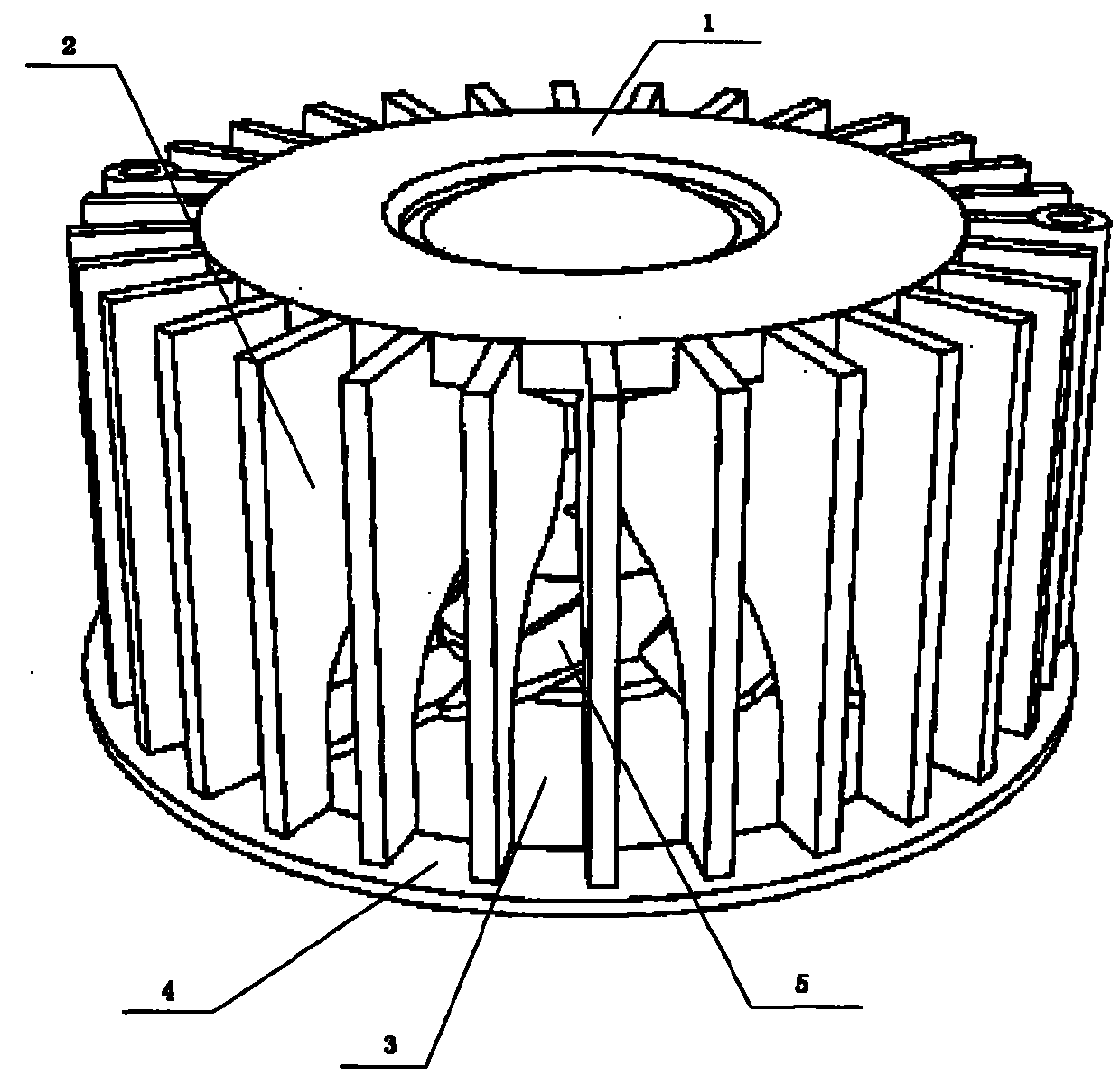

[0015] An LED light-emitting diode radiator, including a heat sink 1 and fins 2, the heat sink 1 is a hollow cylinder structure, the fins 2 are arranged longitudinally along the heat sink 1 cylinder, and the heat sink 1 It is integral with the fin 2 in structure, the length of the fin 2 is greater than the height of the heat sink 1 cylinder, the side of the fin 2 away from the heat sink 1 is a straight line, and the other side has a curve, so The curved side of the fin 2 above forms an open hollow part 3, and the fin 2 is exposed on the end surface of the heat sink 1 and is also provided with a cooling fan 4, and the fan blade 5 of the cooling fan 4 is arranged on the wing Inside the hollow portion 3 formed by the sheet 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com