Method for preparing manganese-doped double-perovskite red fluorescent powder

A technology of red fluorescent powder and double perovskite, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of difficult control of sample particle size, high calcination temperature, and high production cost, so as to facilitate large-scale industrial production, The effect of lowering the calcination temperature and lowering the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

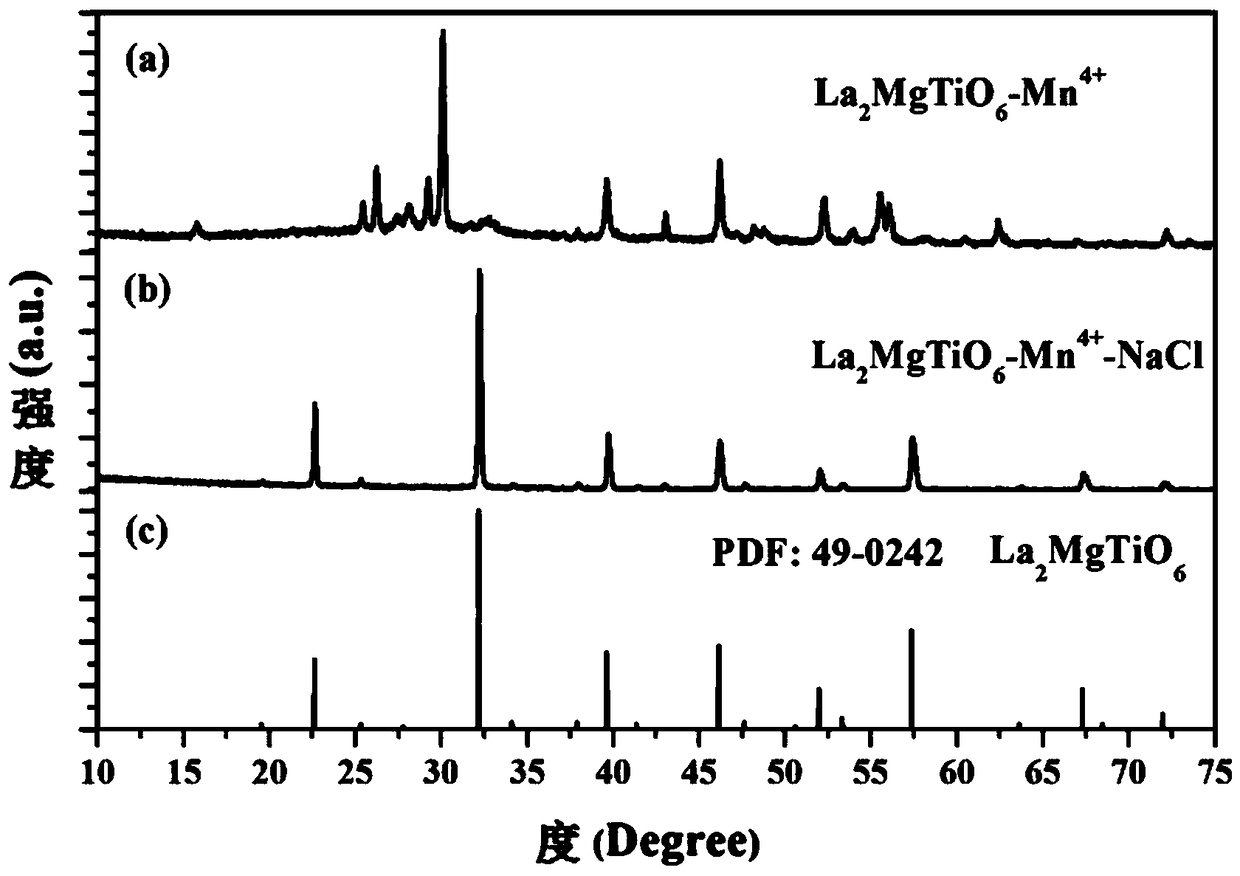

Embodiment 1

[0034] Weigh 16.2905g La2O3, 2.0152g MgO, 3.9735g TiO2, 0.0287g MnCO3, and an appropriate amount of NaCl, grind the above raw materials evenly, put them into a high-temperature furnace, heat evenly from room temperature to 800°C, keep warm for 12 hours, and then cool naturally to room temperature, and wash the product with an appropriate amount of absolute ethanol two to three times, dry in an oven, and cool to room temperature naturally, the composition is La2Mg(Ti0.995Mn0.005)O6.

Embodiment 2

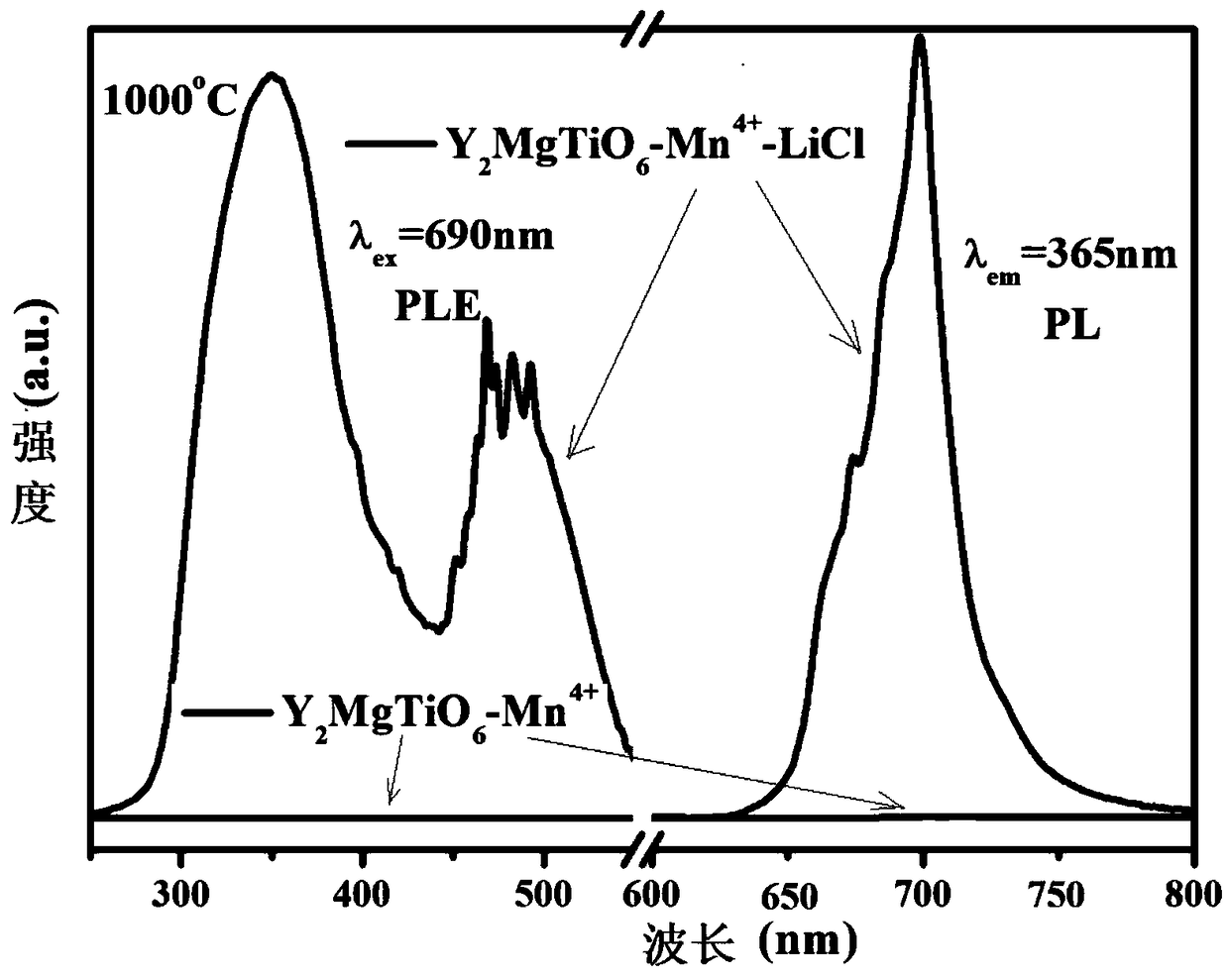

[0036] Weigh 11.2905g Y2O3, 2.0152g MgO, 3.9735g TiO2, 0.0287g MnCO3, and an appropriate amount of LiCl, grind the above raw materials evenly, put them into a high-temperature furnace, heat evenly from room temperature to 1000°C, keep warm for 12 hours, and then cool naturally to room temperature, and wash the product with an appropriate amount of absolute ethanol two to three times, dry in an oven, and naturally cool to room temperature, the composition is Y2Mg(Ti0.995Mn0.005)O6.

Embodiment 3

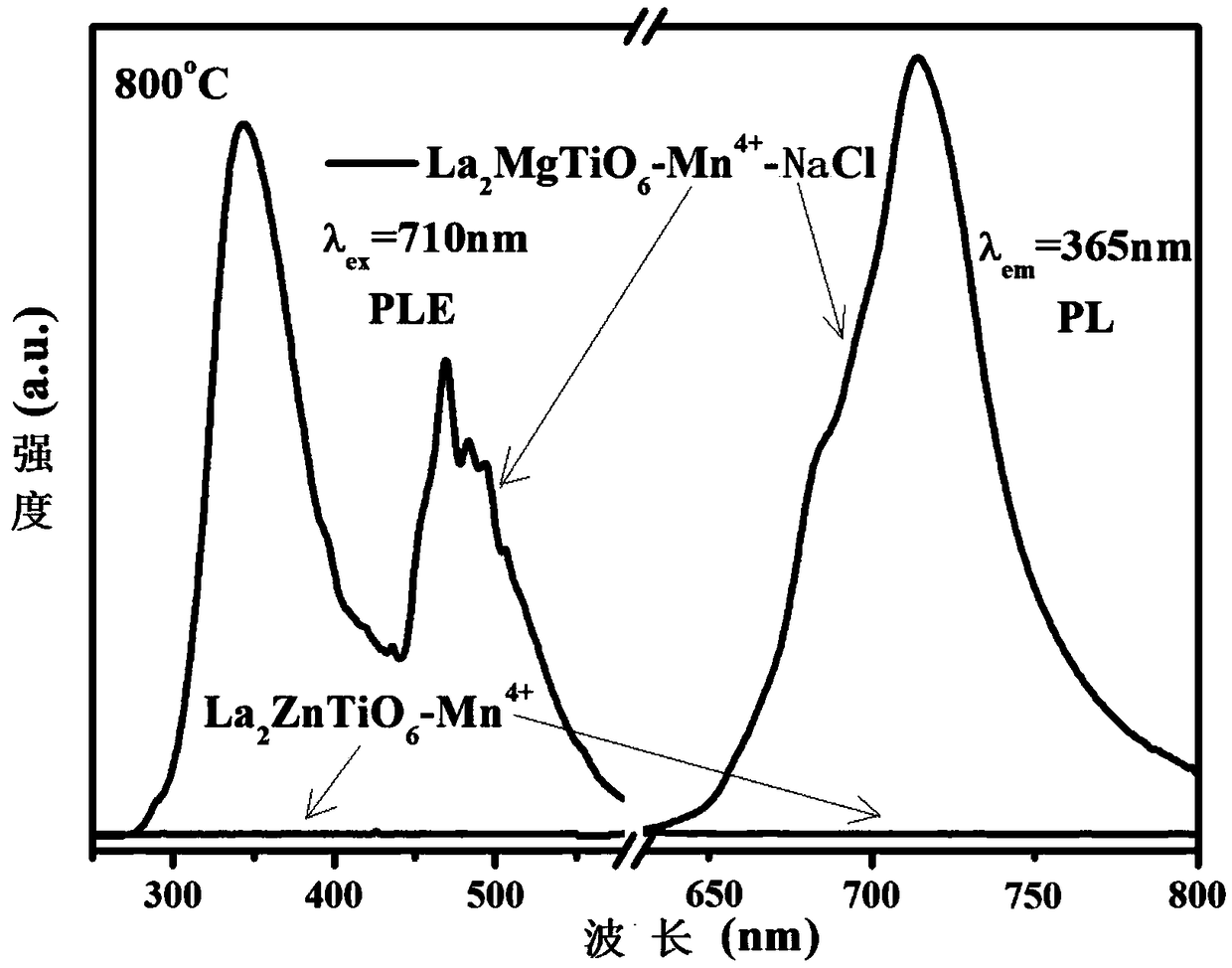

[0038]Weigh 16.2905g La2O3, 4.0690g ZnO, 3.9735g TiO2, 0.0287g MnCO3, and an appropriate amount of KCl, grind the above raw materials evenly, put them into a high-temperature furnace, heat evenly from room temperature to 900°C, keep warm for 12 hours, and then cool naturally After reaching room temperature, add an appropriate amount of absolute ethanol to wash the product two to three times, dry it in an oven, and cool it naturally to room temperature to obtain the composition La2Zn(Ti0.995Mn0.005)O6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com