Method for manufacturing cutter shafts of longitudinally-shearing disc scissors

A manufacturing method and disc technology, which are applied in the manufacturing field of slitting disc scissors shafts, can solve the problems that the measurement accuracy cannot meet the requirements, are not suitable for on-site measurement, and the accuracy cannot meet the requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]A method for manufacturing a slitting disk scissors shaft will be further described in detail below with reference to the accompanying drawings and embodiments.

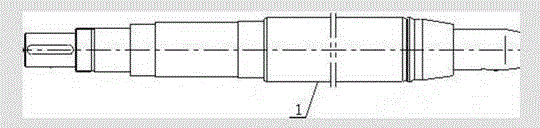

[0044] Such as figure 1 The shown slitting disk scissors shaft is now produced according to the invention.

[0045] A method for manufacturing a slitting disk scissors shaft, comprising the following steps:

[0046] 1) Material selection, the knife shaft material is made of large alloy structural steel forgings; large alloy structural steel forgings are made of 38CrMoAl steel, and 38CrMoAl steel is 38CrMoAl hot-rolled round steel.

[0047] 2) Rough machining and heat treatment are carried out on the selected steel forgings, rough machining is carried out according to the drawing of the high-precision cutter shaft of the slitting disc shears, the allowance after rough machining is controlled at 4-5mm, and the circular runout ↑<0.8mm, during rough machining At the same time, heat treatment is carried out on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com