High-energy density and long-lived MnO2/TiO(1-x)Nx supercapacitor material and preparation thereof

A technology of titanium oxynitride and manganese oxide, which is applied in the field of MnO2/TiO1-xNx supercapacitor materials and preparation, can solve the problems of low charge and discharge cycle life, low power density, and low energy density, and achieve high energy density and high energy density. Effects of power density and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

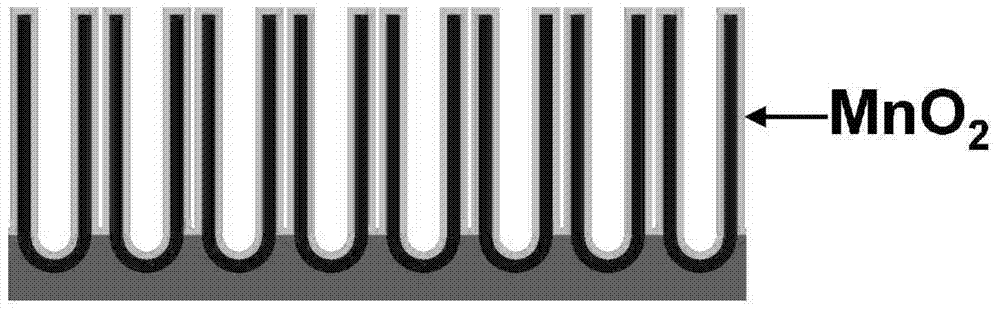

[0017] Preparation of manganese oxide / titanium oxynitride (MnO 2 / TiO 1-x N x ) method for supercapacitor (material), it is characterized in that comprising the following steps:

[0018] (1) Titanium dioxide nanotubes were prepared by anodic oxidation method. A titanium metal foil with a thickness of 50 microns and a purity of 99.8% is used as the anode, one side of which is in contact with an ethylene glycol electrolyte (containing 10% water and 0.1M ammonium fluoride), and the cathode is also made of titanium metal foil. The stability of the electrolyte was maintained at a constant 20°C, and the voltage between the anode and cathode was maintained at 50V. After anodization, the samples were cleaned by ultrasonic to obtain clean TiO 2 array of nanotubes.

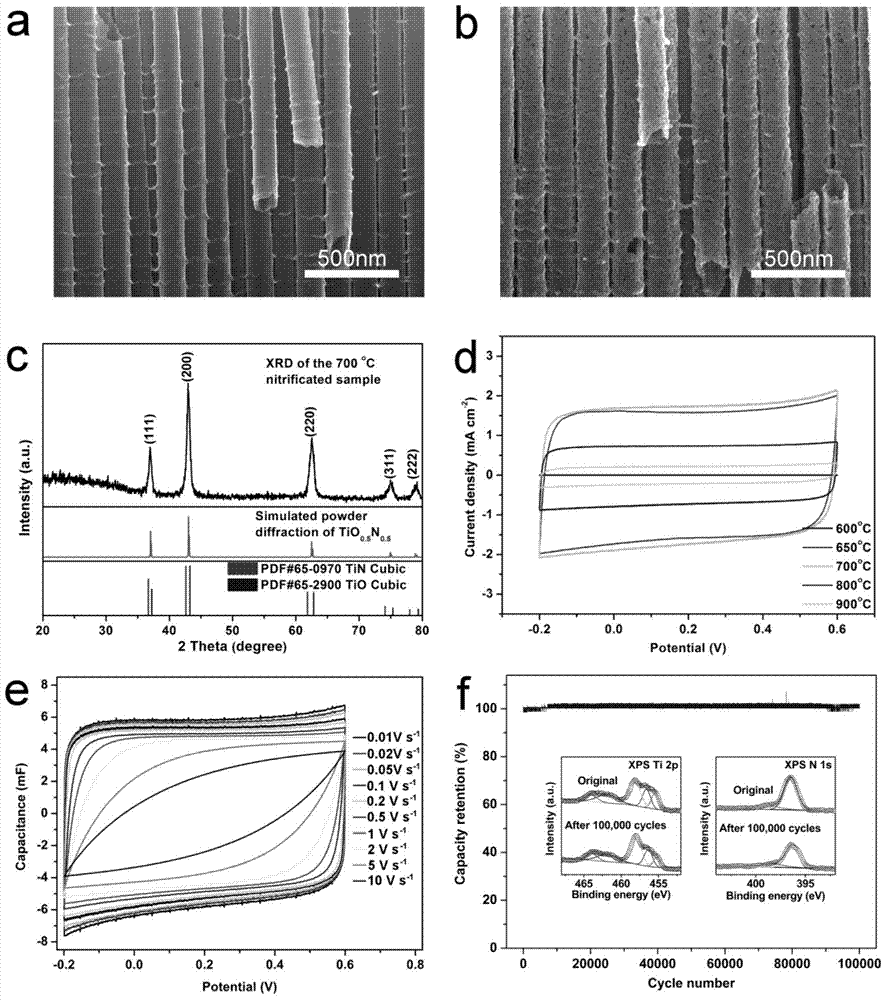

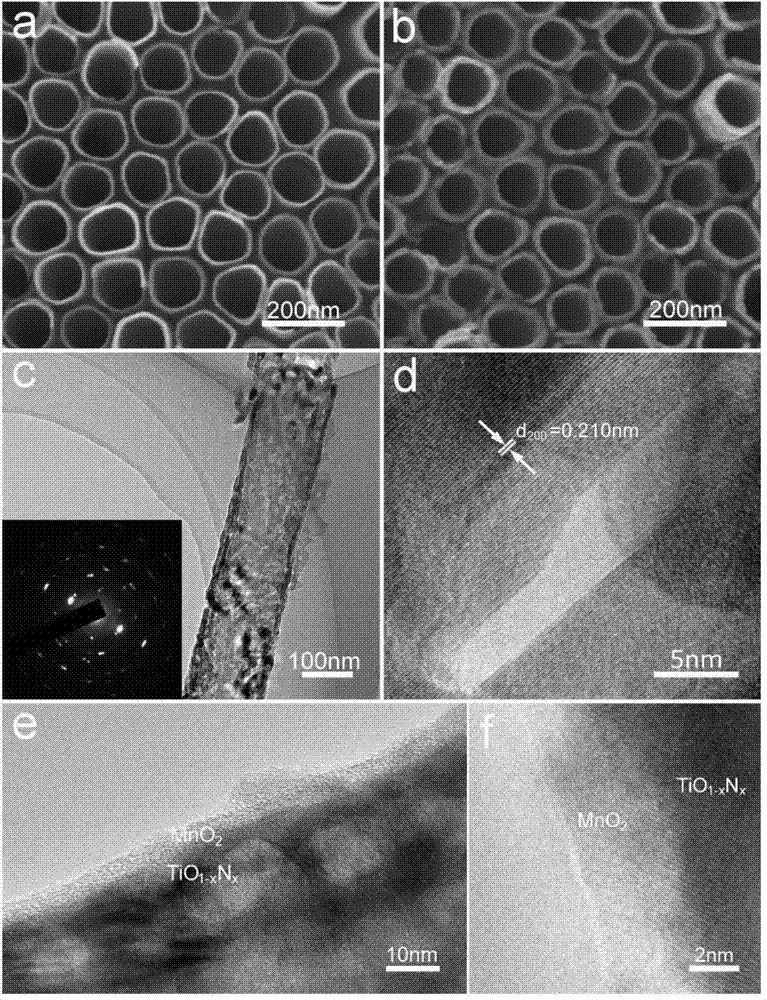

[0019] (2) TiO prepared in step (1) 2 Nanotube arrays were nitrided at different temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com