Laser microscopy processing method of porous surface structure

A technology of porous surface and processing method, which is applied in the field of micromachining of biomedical materials, can solve the problems of inability to position, loose and fall of implants, and unstable combination of metal-bone interface, etc., and achieve huge economic and social value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

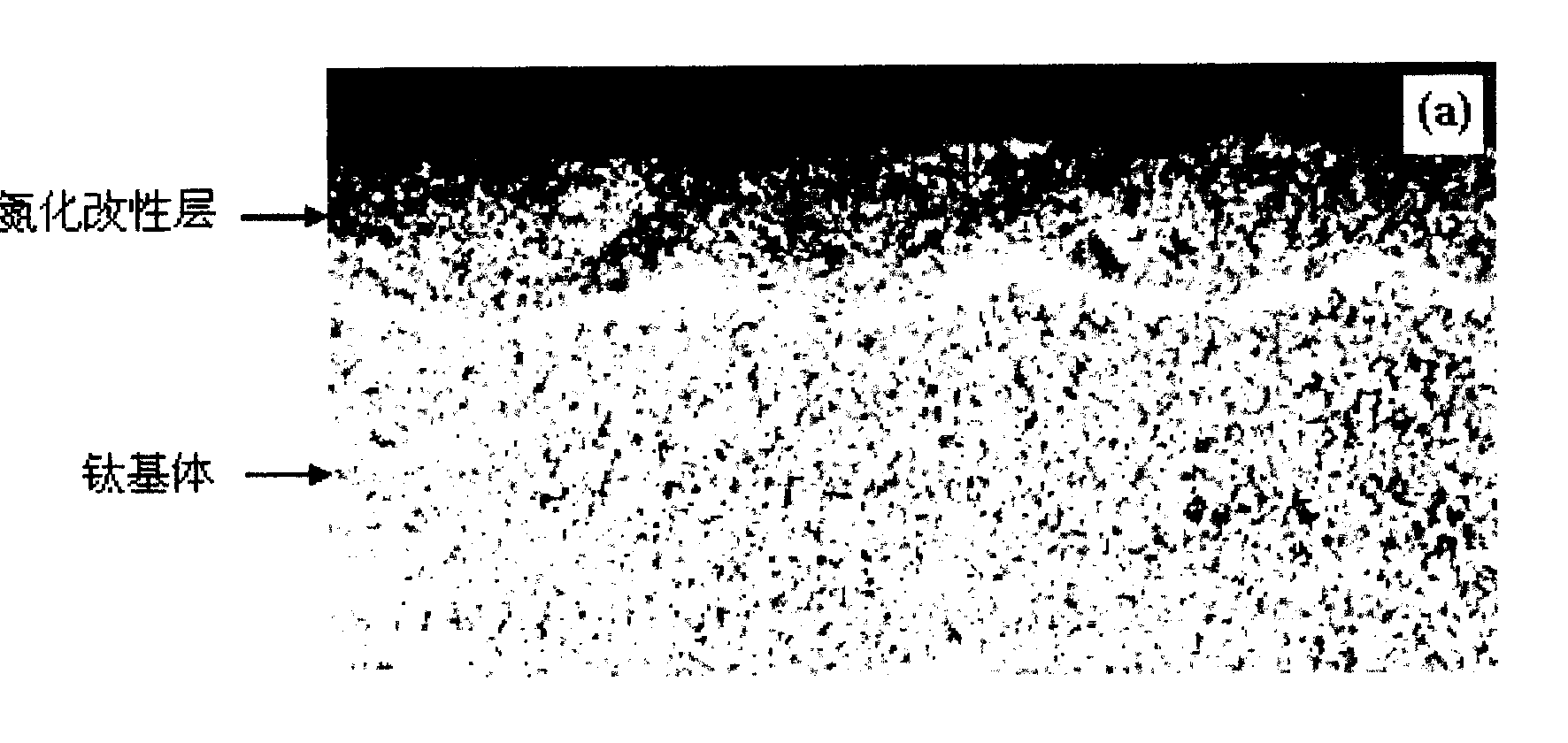

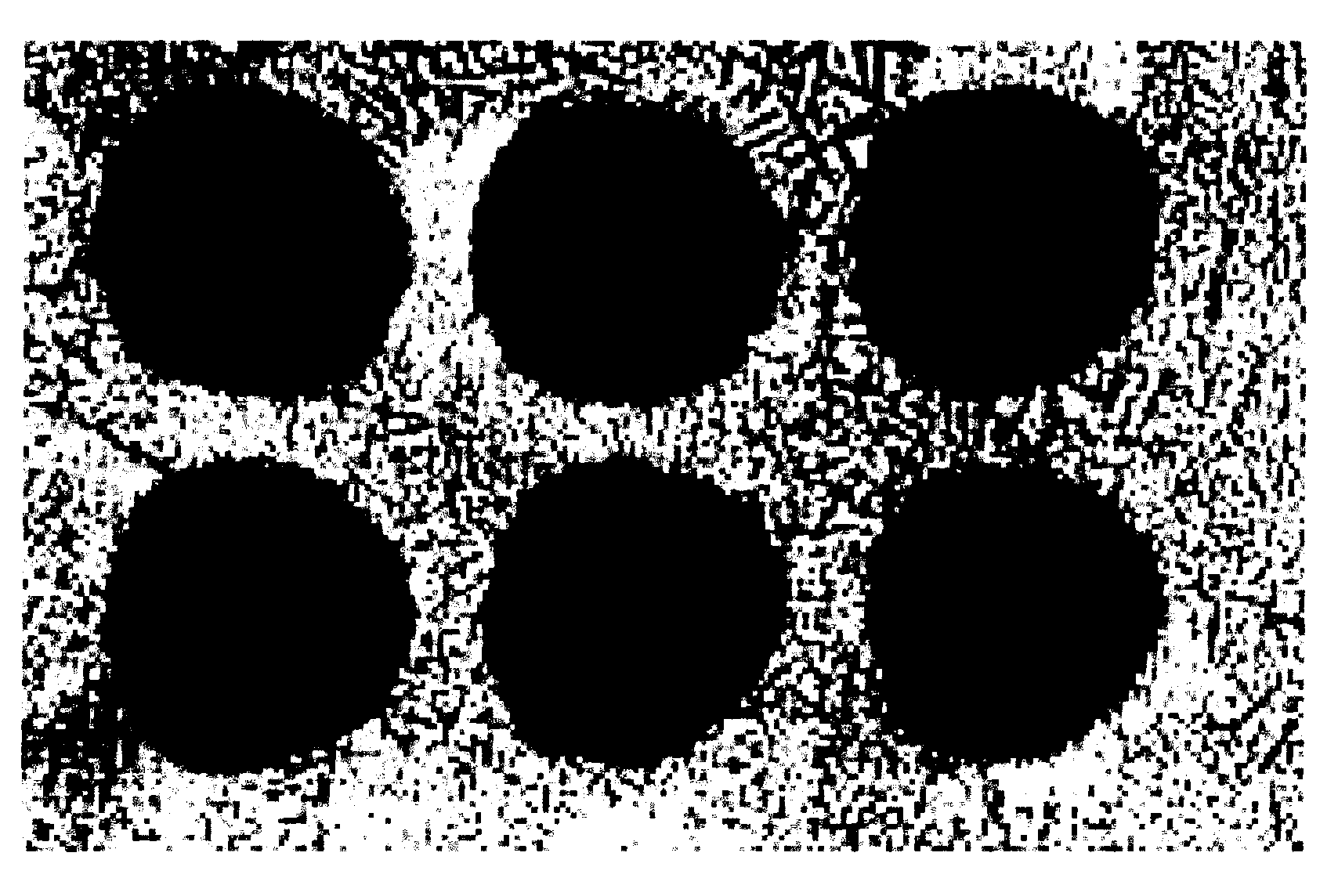

[0042] In this embodiment, a continuous wave Nd:YAG solid-state laser is used to perform laser gas nitriding on 6061Al alloy. The base material is 6061Al alloy, and its chemical composition (wt%) is: 0.4-0.8 Si; 0.7 Fe; 0.15-0.4 Cu; 0.15 Mn; 0.8-1.2 Mg; 0.04-0.35 Cr; 0.25 Zn; 0.15 Ti; Al balance . Laser nitriding process parameters are: laser output power of 1000-1600W, focus of ZnSe lens with 100mm focal length, spot diameter of 1.5-2.5mm, scan rate of 10-35mm / s, nitrogen flow rate of reaction protection chamber of 10-20L / min, sample surface The overlapping rate of large-area laser nitriding treatment is 40-50%. After laser nitriding of 6061Al alloy, a nitrided modified layer with a thickness of 200-500 μm can be obtained on the surface, such as Figure 8 shown. Pulsed Nd:YAG solid-state laser is used for laser micromachining. The process parameters are: pulse power 5-8W, pulse frequency 5-10Hz, pulse number 3-6 times, pulse width 0.5-1ms, and the surface aperture can be o...

Embodiment 2

[0044] The modified layer of Ni-Al and Ti-Al intermetallic compounds can be prepared on the surface of 6061Al alloy by continuous wave high-power Nd-YAG laser. The base material is 6061Al alloy, and the NiTi alloy powder used for surface treatment is of industrial purity, and its chemical composition (at%) is: Ni: 50-54%, Ti: 46-50%. The surface of the 6061Al alloy is sandblasted and cleaned, the NiTi alloy is placed on the surface of the aluminum alloy, and the thickness of the alloy powder is preset on the surface of the aluminum alloy with a thickness of 0.2-0.7mm. A continuous wave Nd-YAG solid-state laser is used for laser cladding treatment, the laser beam wavelength is 1.06 μm, and the ZnSe lens is focused with a focal length of 100 mm. The parameters of the laser treatment process are: power 900-1800W, spot diameter 1-3mm, scanning speed 3-20mm / s, argon gas flow in the protection chamber 10-30L / min. The optimal laser processing parameters are: power 1600W, spot diamet...

Embodiment 3

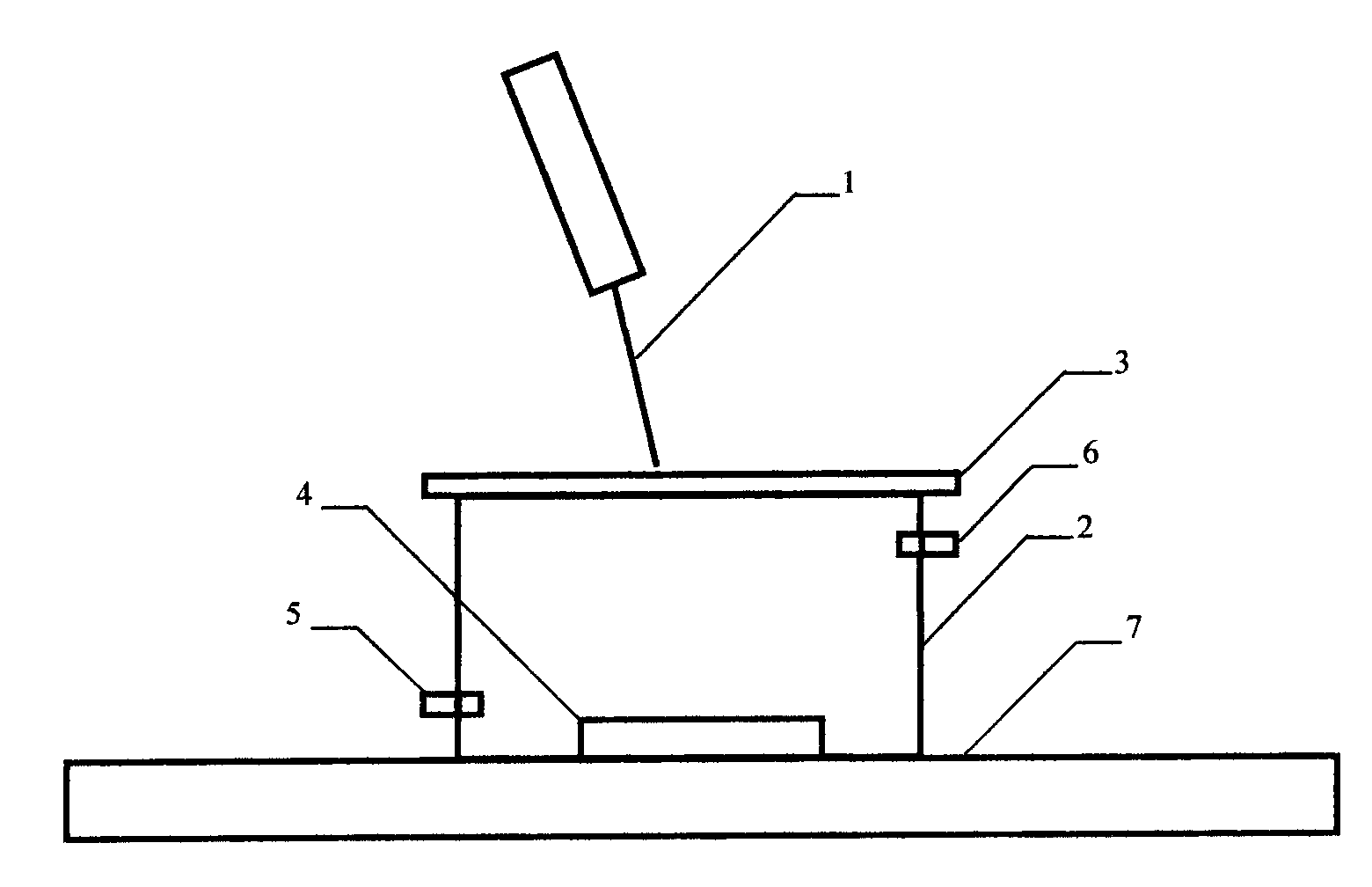

[0046] In this embodiment, a continuous wave Nd:YAG solid-state laser is used to carry out laser gas nitriding on the surface of medical titanium alloy. The nitriding process parameters are as follows: laser output power is 500-700W, ZnSe lens focusing with 100mm focal length, spot diameter 1.5-2.0 mm, scan rate 5-8mm / s, reaction chamber nitrogen flow rate 10-20L / min, large-area laser nitriding treatment overlap rate of sample surface 40-50%, laser gas nitriding test device such as figure 1 As shown, after the material is nitridated by laser, laser micromachining is carried out with a pulsed Nd:YAG solid-state laser. The process parameters are: pulse power 8W, pulse frequency 10Hz, pulse number 4 times, and pulse width 1ms.

[0047] The large-area laser nitriding treatment on the surface of the sample has an overlapping rate of 50-80%; the ratio of the maximum diameter of the bottom of the micropore to the diameter of the hole is 1.3-1.8.

[0048] figure 2 , 3 , 4 is the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com