Manufacturing apparatus and method for large-scale production of thin-film solar cells

A technology of solar cells and conductive films, applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

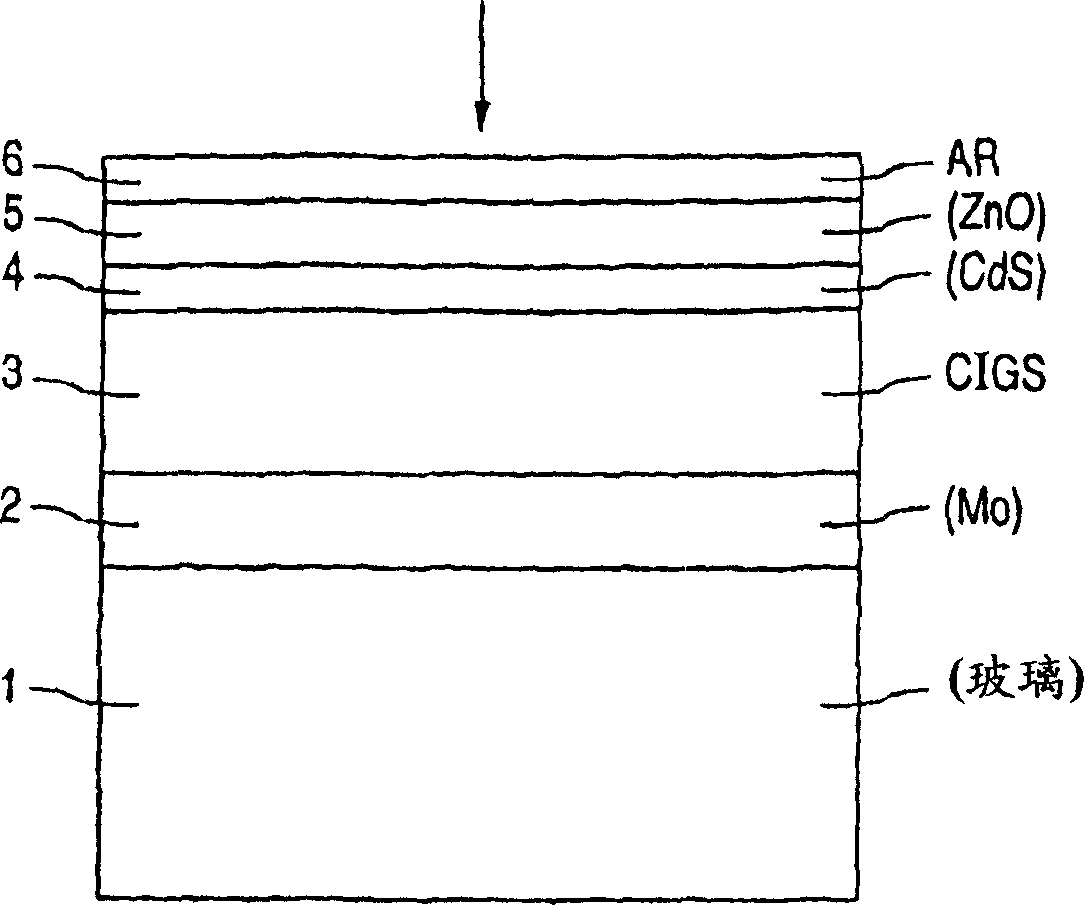

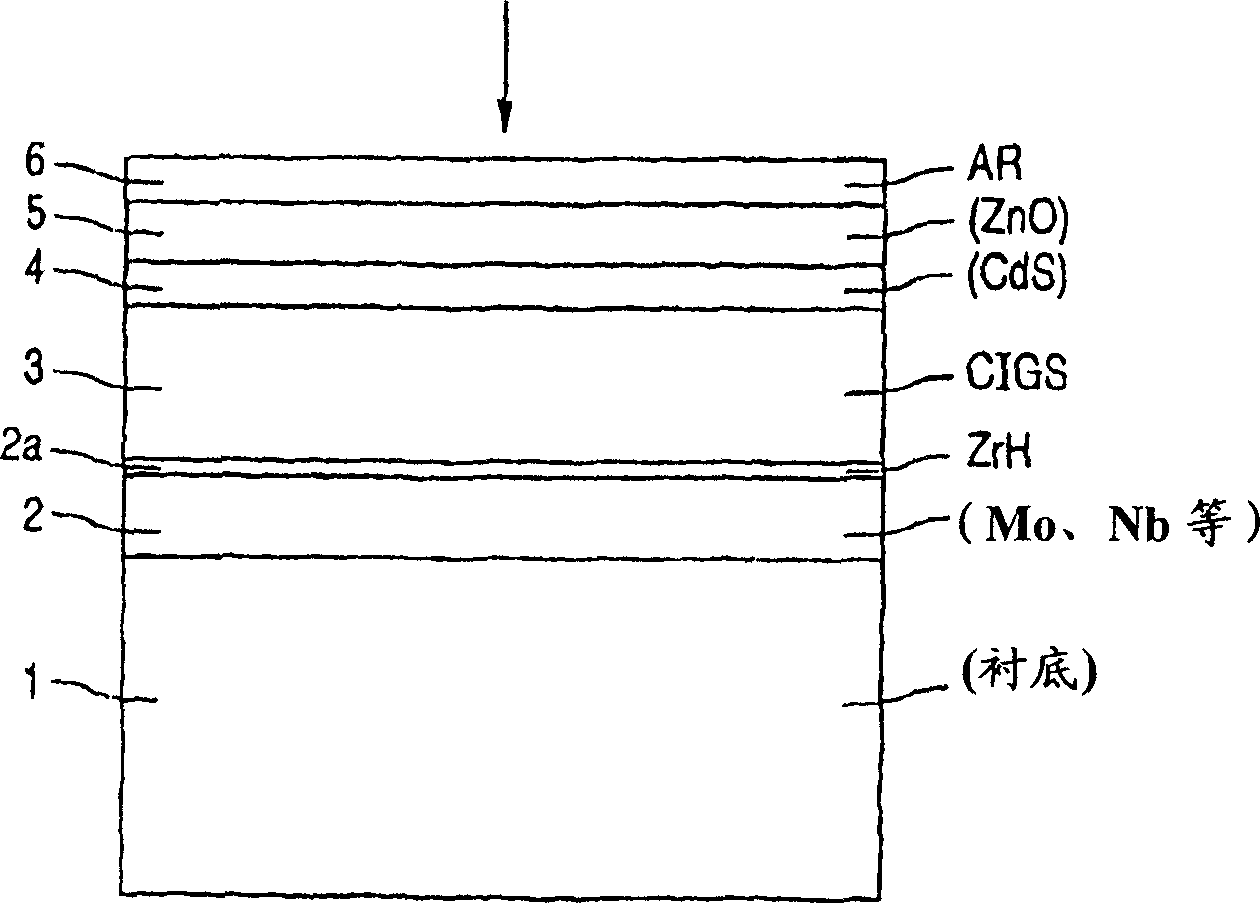

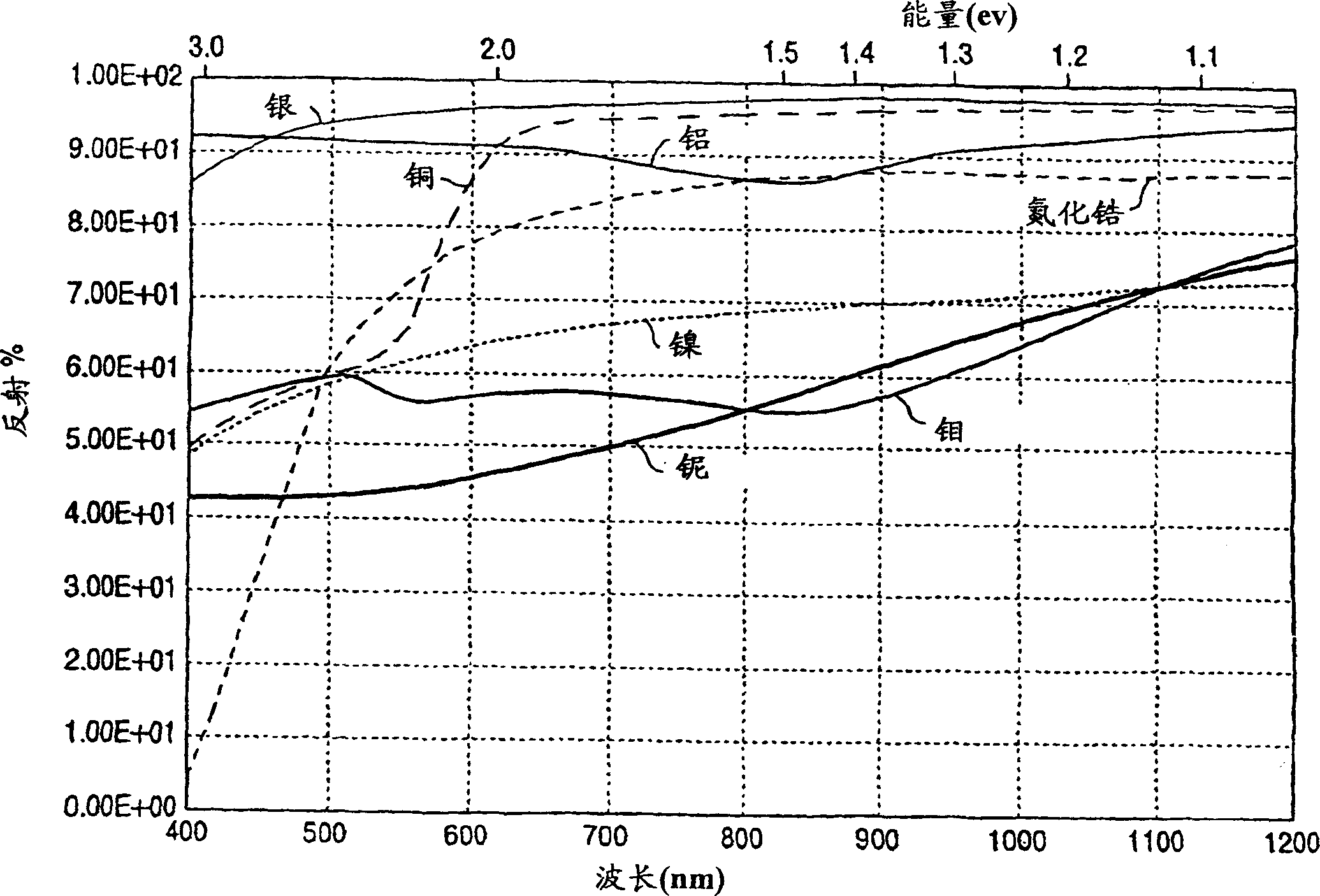

[0055] Now, the present invention will be described and compared with the structure of a conventional prior art CIGS solar cell. A new cell structure and fabrication process will be detailed for a modular roll-to-roll sputter deposition system specifically designed to provide optimal realization of the process.

[0056] It should be noted that, as used herein, the terms "over" and "on" both inherently include "directly on.. ..." (without intervening materials, elements, or spaces disposed therebetween), and "indirectly over" (intermediate materials, elements, or spaces disposed therebetween). For example, forming a unit "on a substrate" may include directly forming a unit on a substrate without intermediate materials / units therebetween, and may also include indirectly forming a unit on a substrate with one or more intermediate materials / units therebetween.

[0057] Figure 6 A simplest embodiment of a basic solar cell according to the invention comprising a barrier layer of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com