Transition metal nitride/nitrogen-doped graphene nanometer composite material and preparation method and application thereof

A technology of nitrogen-doped graphene and nanocomposite materials, which is applied in the field of electrochemistry, can solve the problems of long preparation process, achieve simple process, novel structure, and improve the speed of electron conduction and ion conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The present embodiment provides a kind of preparation method of vanadium nitride / nitrogen-doped graphene (VN / NG) nanocomposite material, and its specific preparation method is:

[0073] (1) 12g ammonium dicyanide, 0.4g glucose, 0.2g ammonium metavanadate (the mass ratio of the template precursor and the carbon source is 30:1, and the mass ratio of the carbon source and the metal source is 2:1) in a ball mill In 500r / min rotating speed, mix 30min to obtain the mixed material;

[0074] (2) Place the mixed material described in step (1) in an atmosphere furnace, feed nitrogen, the flow rate of the gas is 40mL / min, and the first stage of calcination is heated up to 600°C at a heating rate of 2.5°C / min, After 4 hours of heat preservation, the second stage of calcination was raised to 800°C at a heating rate of 2°C / min, held for 4 hours, and then cooled down to room temperature under the protection of nitrogen to obtain VN / NG nanocomposites.

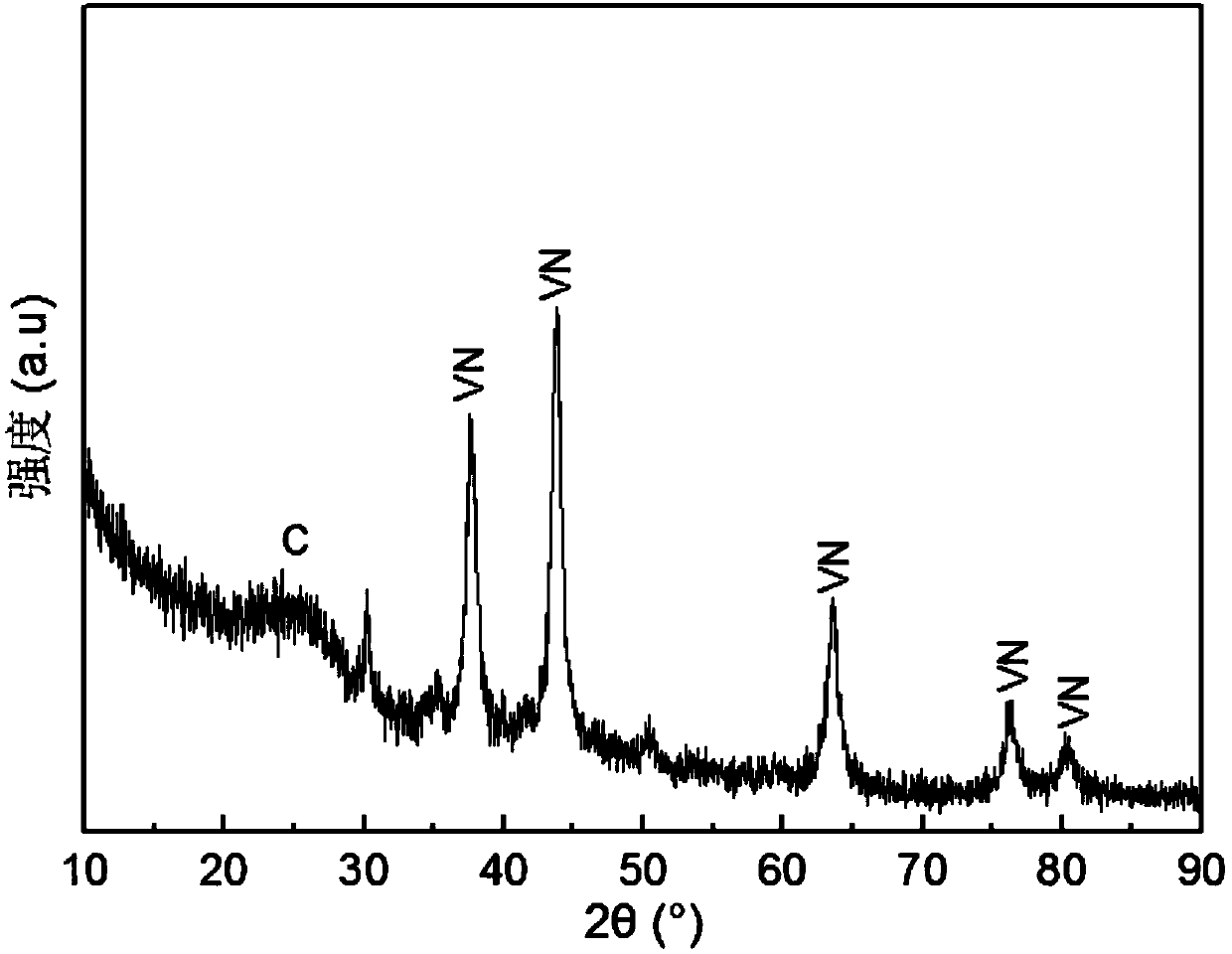

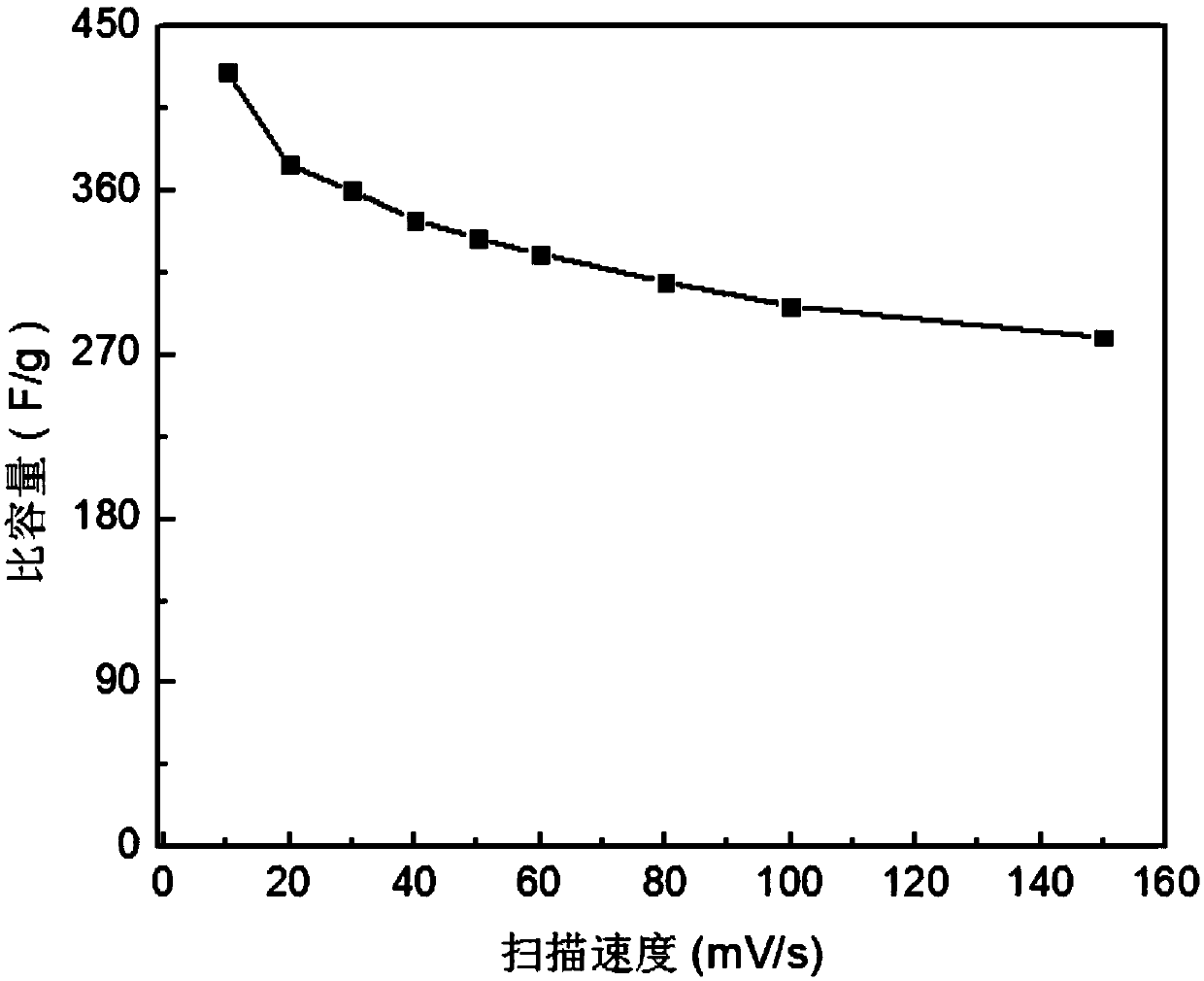

[0075] In the VN / NG nanocomposi...

Embodiment 2

[0082] This embodiment provides a kind of preparation method of VN / NG nanocomposite material, and its specific preparation method is:

[0083] (1) 12g ammonium dicyanide, 0.6g glucose, 0.12g ammonium metavanadate (the mass ratio of the template precursor and the carbon source is 20:1, and the mass ratio of the carbon source and the metal source is 5:1) in a ball mill Mix 40min under the rotating speed of 550r / min to obtain the mixed material;

[0084] (2) Place the mixed material described in step (1) in an atmosphere furnace, feed nitrogen, the flow rate of the gas is 40mL / min, and the first stage of calcination is heated up to 650°C at a heating rate of 5°C / min, After 2 hours of heat preservation, the second stage of calcination was raised to 1200°C at a rate of 4°C / min, held for 1 hour, and then cooled down to room temperature under the protection of nitrogen to obtain VN / NG nanocomposites.

[0085] In the VN / NG nanocomposite prepared in this example, VN is embedded in the...

Embodiment 3

[0087] This embodiment provides a kind of preparation method of VN / NG nanocomposite material, and its specific preparation method is:

[0088] (1) 12g ammonium dicyanide, 0.3g glucose, 0.1g ammonium metavanadate (the mass ratio of the template precursor and the carbon source is 40:1, and the mass ratio of the carbon source and the metal source is 3:1) in a ball mill Mix 30min under the rotating speed of 600r / min to obtain the mixed material;

[0089] (2) Put the mixed materials described in step 1 in an atmosphere furnace, feed nitrogen gas, the flow rate of the gas is 400mL / min, the first stage of calcination is heated up to 600°C at a heating rate of 3°C / min, and kept for 4h In the second stage of calcination, the temperature was raised to 900°C at a heating rate of 2°C / min, kept for 4h, and then cooled down to room temperature under the protection of nitrogen to obtain VN / NG nanocomposites.

[0090] In the VN / NG nanocomposite material prepared in this example, VN is embedd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com