Transition metal-nitrogen doped carbon composite material and preparation method thereof

A carbon-based composite material, transition metal technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of complex preparation methods, unfavorable large-scale production, long reaction time, etc. The preparation method is simple and fast, suitable for large-scale production and preparation, and the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The steps for preparing transition metal-nitrogen doped carbon-based composites are as follows:

[0037] 1) At room temperature, dissolve 0.5mmol ferrous chloride and 238mmol urea in deionized water, stir at a stirring speed of 600rpm for 2.5 hours to form a homogeneous solution, and place the homogeneous solution at 65°C for 12 hours to evaporate the water Afterwards, grind into powder;

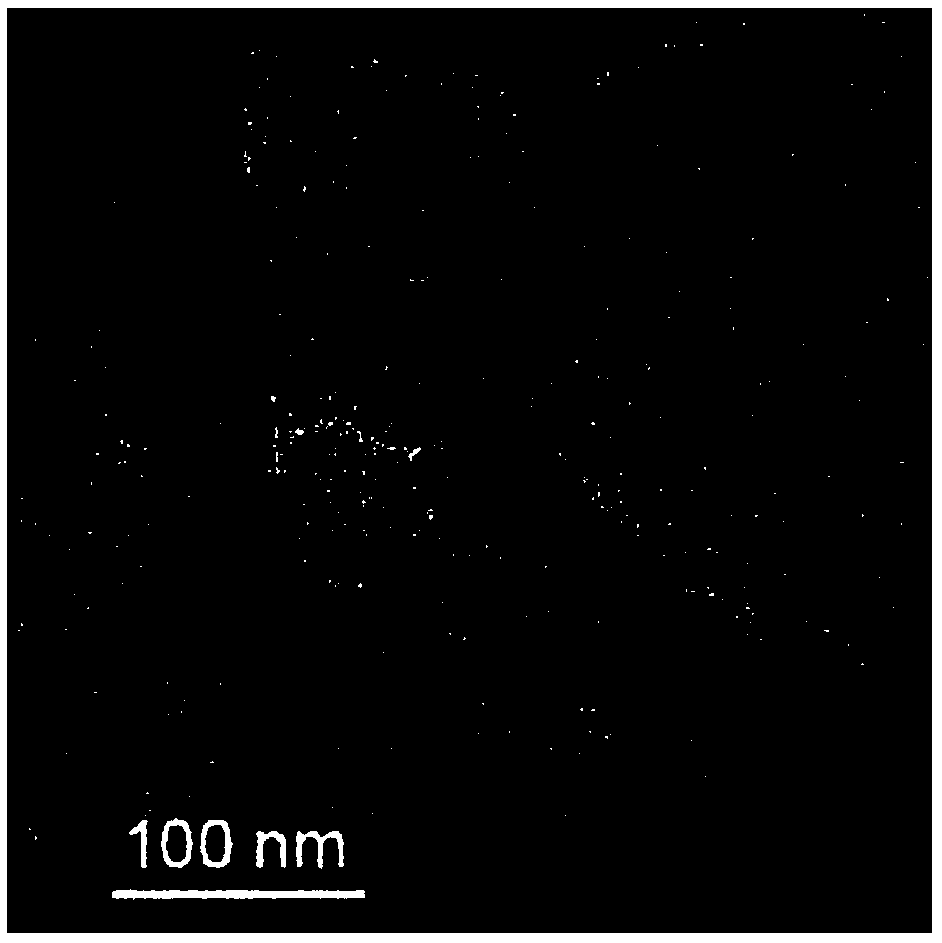

[0038]2) Calcining the powder obtained above, the heating rate is 2.5°C / min, the calcination temperature is 550°C, and the calcination time is 3 hours. After the reaction is stopped, it is naturally cooled to room temperature and fully ground to obtain the transition metal element iron doped g-C 3 N 4 Precursor powder, its transmission electron microscope picture is as follows figure 1 shown;

[0039] 3) Doping g-C with transition metal element iron 3 N 4 The precursor powder was carbonized at high temperature, the heating rate was 2.3°C / min, the carbonization temperature was 650...

Embodiment 2

[0042] In this example, except that the nitrogen-containing organic small molecule in step 1 is dicyandiamine, the rest of the steps are the same as in example 1 to obtain a sheet-like transition metal iron and nitrogen-doped carbon-based composite material.

Embodiment 3

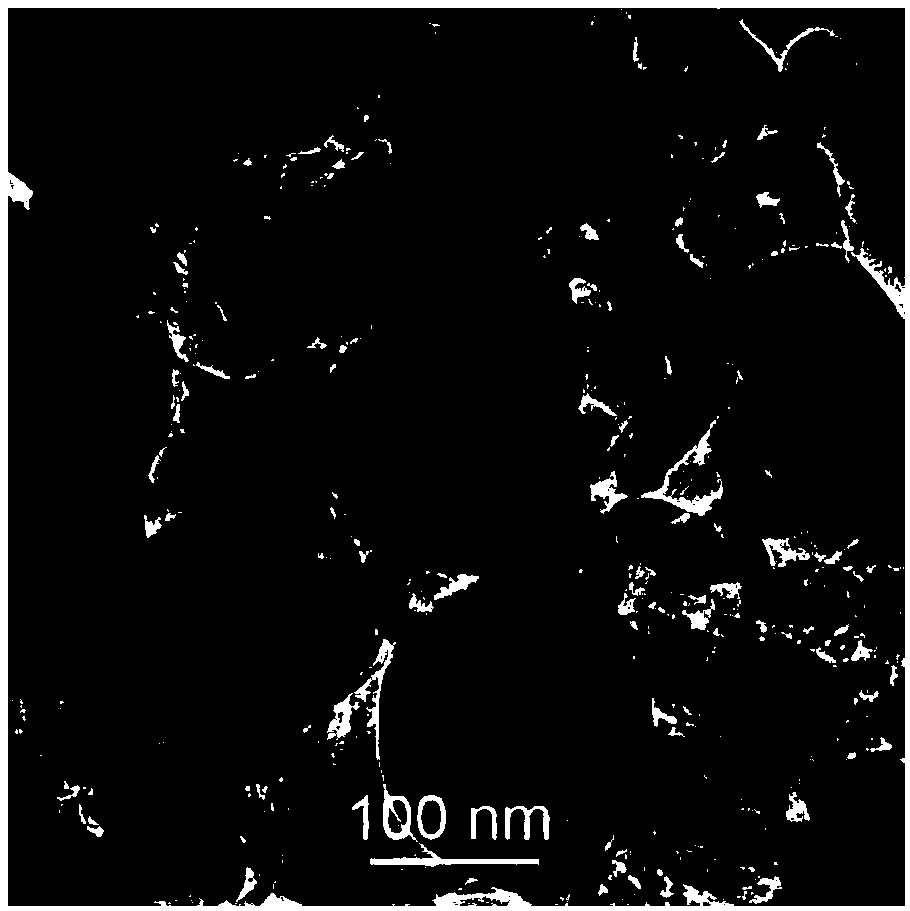

[0044] In the present embodiment, except that the ferrous chloride added in step 1 is 1 mmol and the concentration of dilute hydrochloric acid in step 4 is 0.25mol / L, all the other steps are the same as in embodiment 1, and the transition metal iron, Nitrogen-doped carbon-based composite; its transmission electron microscope scanning image is shown in image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com