Industrial preparation method of smart glass capable of automatically regulating infrared transmittance

A technology of infrared transmittance and automatic adjustment, applied in the fields of doping, toning preparation, and PVD deposition, can solve the problems such as the industrial application of vanadium dioxide-based smart glass, which can meet market needs and reduce process costs. , to achieve the effect of color change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] An industrialized preparation method for intelligent glass with automatic adjustment of infrared transmittance, the steps are as follows:

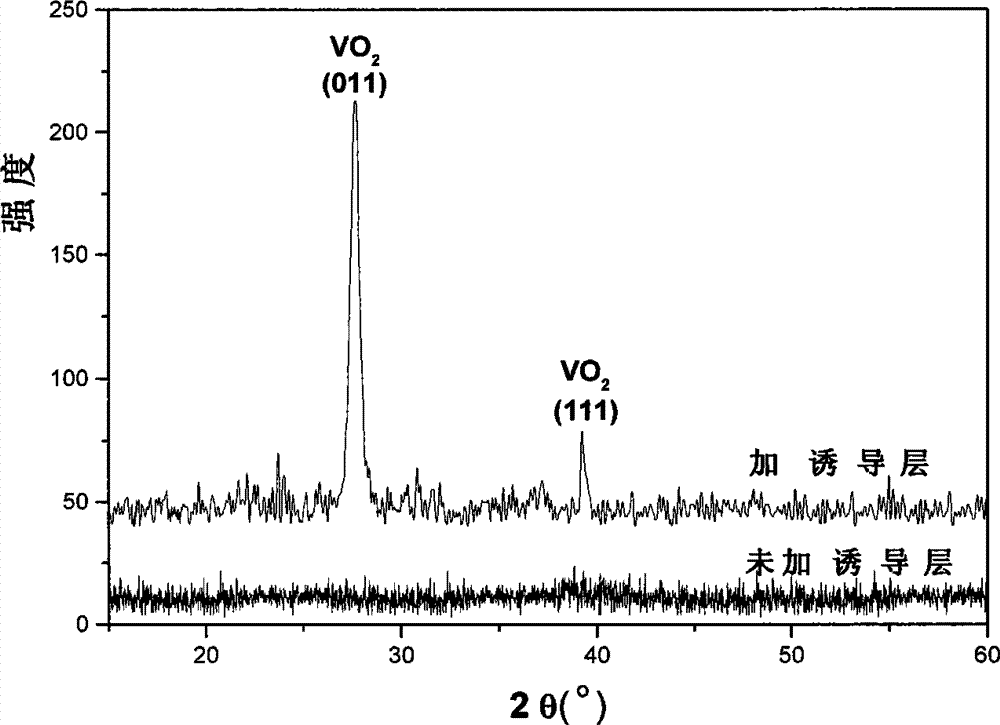

[0030] (1) Preparation of crystallization-inducing layer on glass surface

[0031] After the glass is routinely cleaned, a 5-20nm thick Ti or Si elemental film is sputtered and deposited on the glass surface by ion beam sputtering as a crystallization induction layer; or chemical vapor deposition is used on the cleaned glass surface ( PECVD) method deposits SiNx thin film of 40~80nm, as crystallization induction layer;

[0032] (2) Deposition of Vanadium Oxide Thin Film by DC Reactive Magnetron Sputtering

[0033] Using the DC reactive magnetron sputtering method, the vanadium oxide film is deposited on the crystallization induction layer by reactive sputtering; the reactive sputtering target is made of high-purity vanadium with a purity of 99.96% and doping elements with different atomic ratios; reactive sputtering Radiation sour...

Embodiment 1

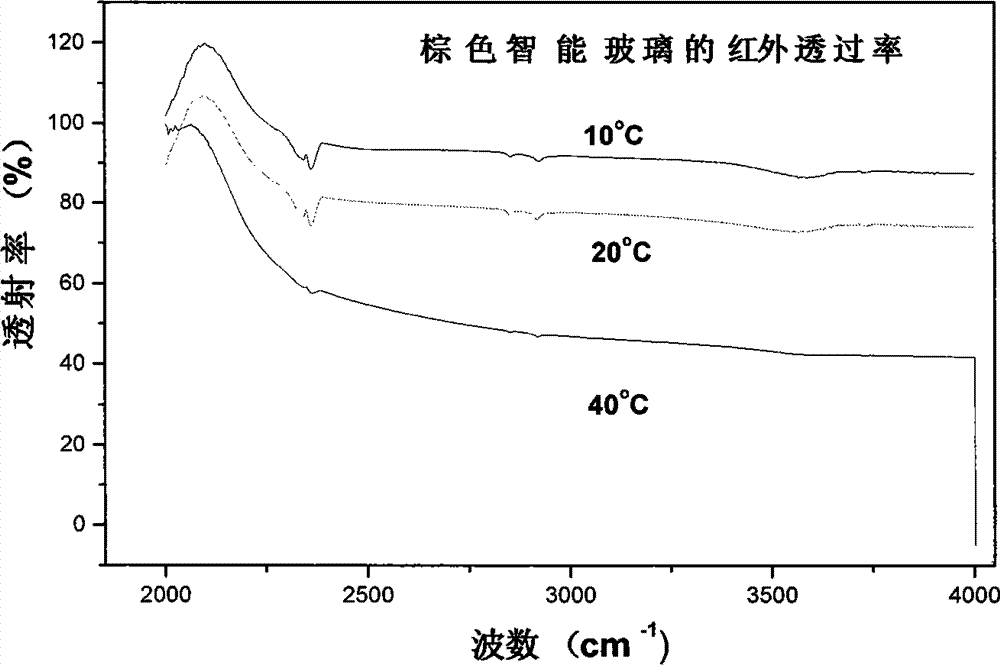

[0037] Embodiment 1 Brown smart glass preparation

[0038] 1. Preparation of crystallization-inducing layer on glass surface

[0039] After routine glass cleaning, chemical vapor deposition (PECVD) is used to deposit 70nm thick silicon-rich silicon nitride at 200°C as a crystallization induction layer, and its refractive index is 2.07;

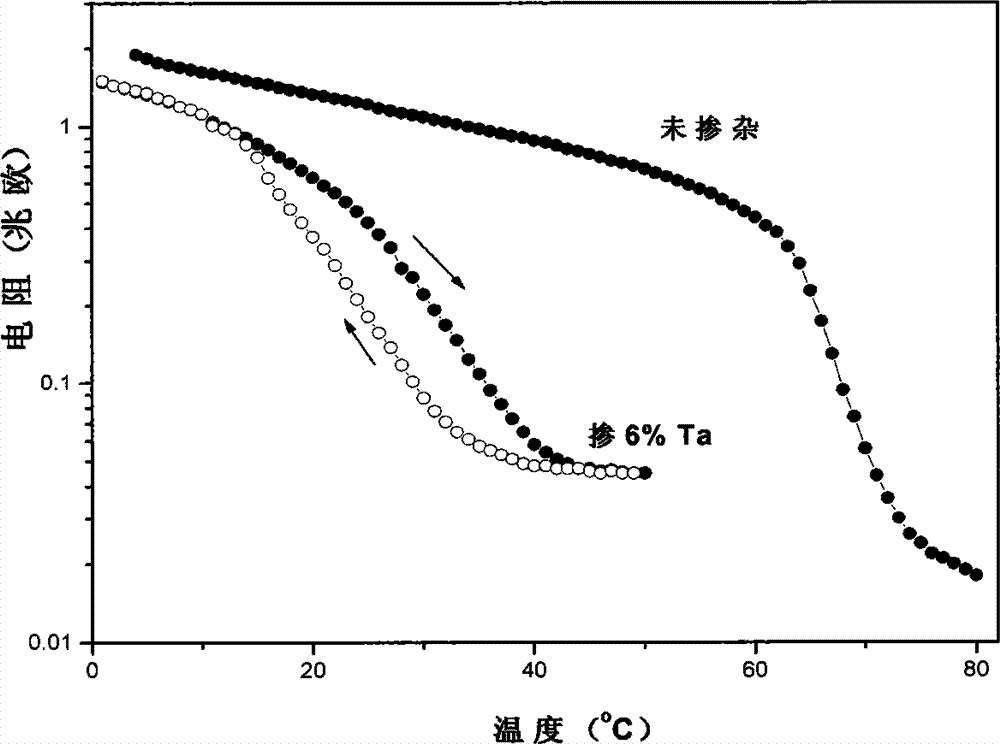

[0040] 2. DC reactive magnetron sputtering vanadium oxide film deposition

[0041] Using the DC reactive magnetron sputtering method, the vanadium oxide film was deposited on the crystallization induction layer by reactive sputtering; the reactive sputtering target was purchased 94% high-purity (99.96%) V and Ta with an atomic ratio of 6%. (purity 99.99%) molten alloy target. Reactive sputtering source gas is Ar / O 2 Mixed gas, Ar / O 2 The flow ratio is 8%, and the background vacuum of the sputtering chamber is 5×10 -4 Pa, the working vacuum degree during sputtering is 0.5Pa. During sputtering, a negative bias of 200V was applied to the sa...

Embodiment 2

[0045] Example 2 Preparation of blue smart glass

[0046] 1. Preparation of crystallization-inducing layer on glass surface

[0047] After the glass is routinely cleaned, use the ion beam sputtering method to deposit Ti with a purity of 99.99% on the glass surface with Ar ion sputtering, the sputtering acceleration voltage is 1500V, and the ion beam density is 0.4mA / cm 2 , the working vacuum degree is 1Pa, the sputtering deposition time is 5 minutes, and the thickness of the deposited Ti crystallization induction layer is about 10nm.

[0048] 2. DC reactive magnetron sputtering vanadium oxide film deposition

[0049] A direct current reactive magnetron sputtering method is used to deposit a vanadium oxide film on the crystallization induction layer by reactive sputtering; the deposited vanadium oxide film is a doped vanadium oxide film with a thickness of 180nm. The target material for reactive sputtering is a molten alloy target of 96% V (99.96% purity) and 1% La plus 3% Pd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com