Monitoring system for on-line monitoring of optical fiber quality

A monitoring system and quality technology, which is applied in the direction of program control, measuring device, optical instrument test, etc. in the sequence/logic controller, and can solve the problems of lack of data statistics and analysis, timely alarm not involved in online monitoring quality problems, etc. , to achieve the effects of ensuring timeliness, facilitating daily maintenance, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

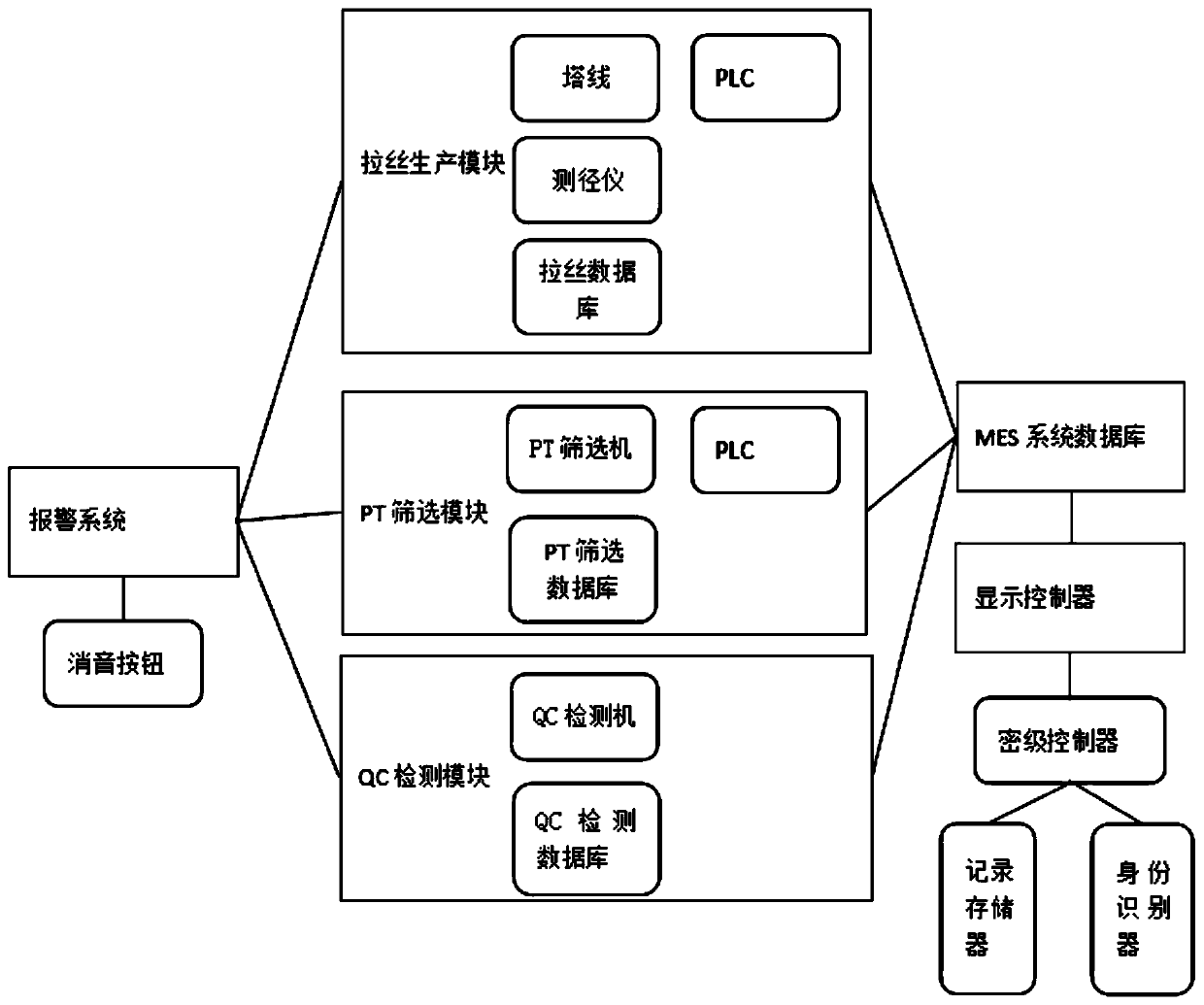

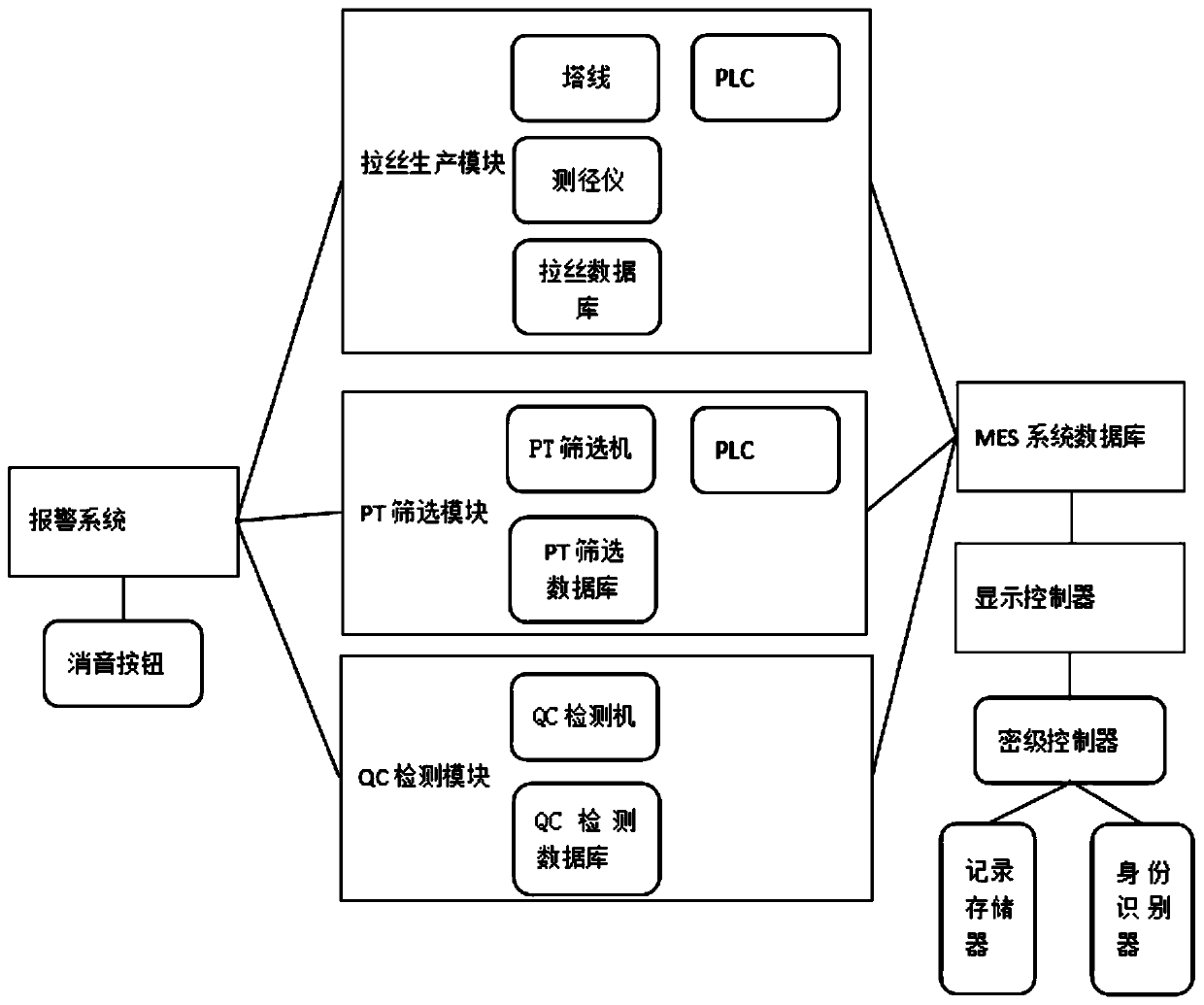

[0021] Such as figure 1 Shown: a monitoring system for online monitoring of optical fiber quality, characterized in that: it includes a wire drawing production module, a PT screening module, a QC detection module, an MES system database, an alarm system and a display controller; the wire drawing production module includes a tower wire, Caliper and wire drawing database, the PT screening module includes a PT screening machine and a PT screening database, the QC testing module includes a QC testing machine and a QC testing database, and the tower line and the PT screening machine are equipped with programmable controllers (PLC); the drawing production module, the PT screening module and the QC detection module are connected to the MES system database and the alarm system, and the MES system database is connected to a display controller, and the display controller includes "drawing production", "PT screening ", "QC detection" three interfaces, and the display controller is connec...

Embodiment 2

[0025] Such as figure 1 Shown: a monitoring system for online monitoring of optical fiber quality, characterized in that: it includes a wire drawing production module, a PT screening module, a QC detection module, an MES system database, an alarm system and a display controller; the wire drawing production module includes a tower wire, Caliper and wire drawing database, the PT screening module includes a PT screening machine and a PT screening database, the QC testing module includes a QC testing machine and a QC testing database, and the tower line and the PT screening machine are equipped with programmable controllers (PLC); the drawing production module, the PT screening module and the QC detection module are connected to the MES system database and the alarm system, and the MES system database is connected to a display controller, and the display controller includes "drawing production", "PT screening ", "QC detection" three interfaces, and the display controller is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com