Camera obscura system for automatic test of low-light image intensifier

A low-light image intensifier and automatic testing technology, which is applied in the field of black box system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

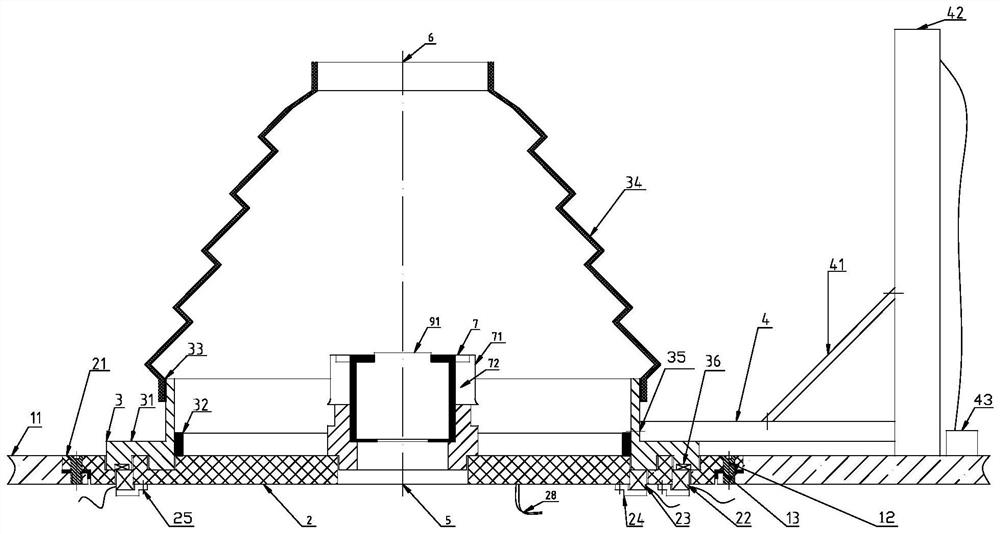

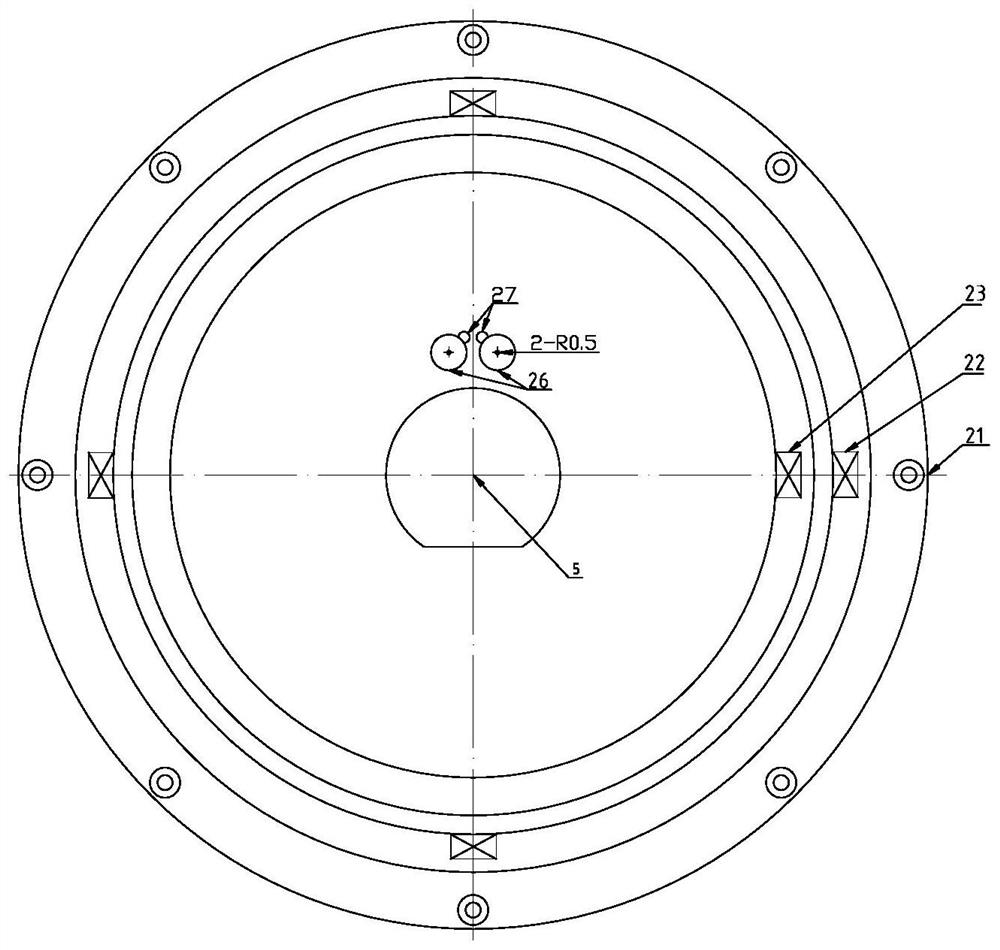

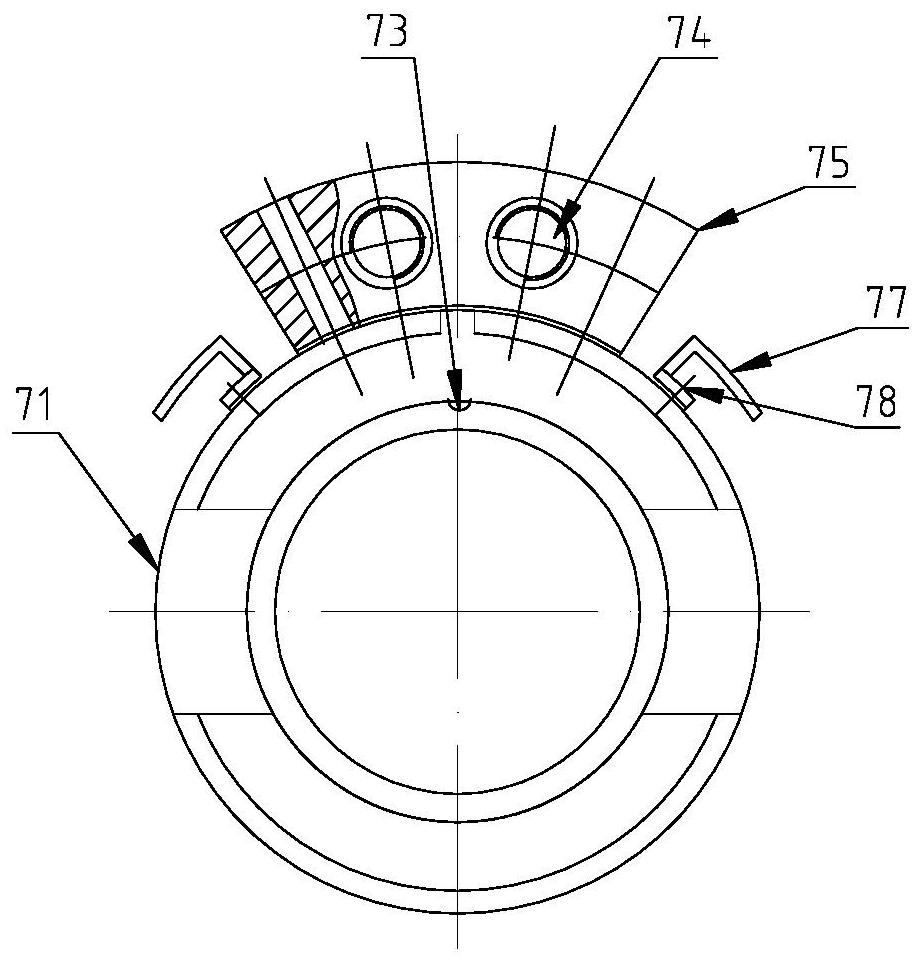

[0042] The dark box system for automatic testing of low-light image intensifiers of the present invention is mainly composed of a desktop 11, a vertical light path dark box assembly 3, a dark box bottom plate assembly 2, a lifting platform assembly 4, a test shell assembly 7, and a power contact nail assembly 8. . The center position of the camera obscura bottom plate assembly 2 is positioned and the test shell assembly 7 and the test shell assembly 7 are black anodized. Black insulating plastic, such as black acetal resin, together constitute the main body of the camera obscura, the lifting platform assembly 4 fixes the vertical optical path camera obscura assembly 3 and can be programmed to lift the vertical optical path camera obscura assembly 3, and the test shell assembly 7 is used for positioning and installing the image intensifier 91, The power contact nail assembly 8 is installed on the power contact nail mounting base 75 for electrical connection of the image intensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com