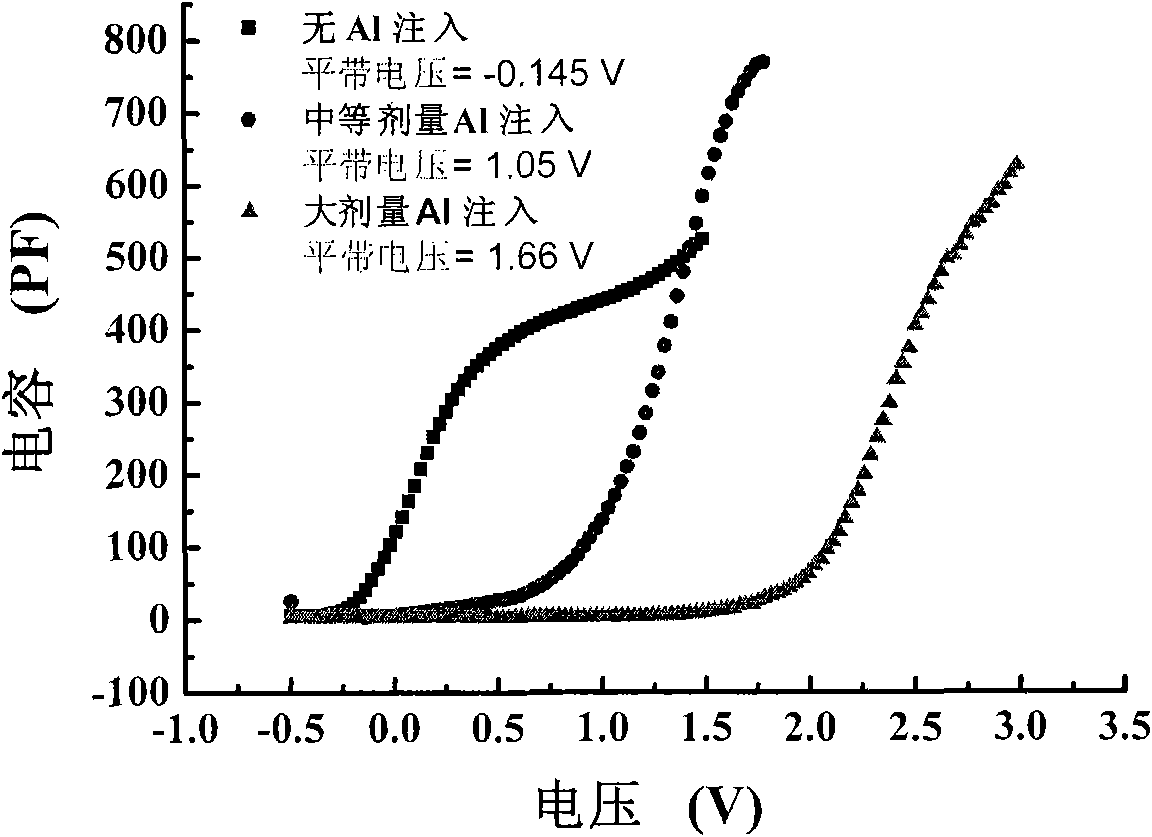

Adjustment method of bimetal gate work function

An adjustment method and double metal gate technology, applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., to achieve good thermal stability and adjust the work function of metal gates, facilitate industrialization, and the method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

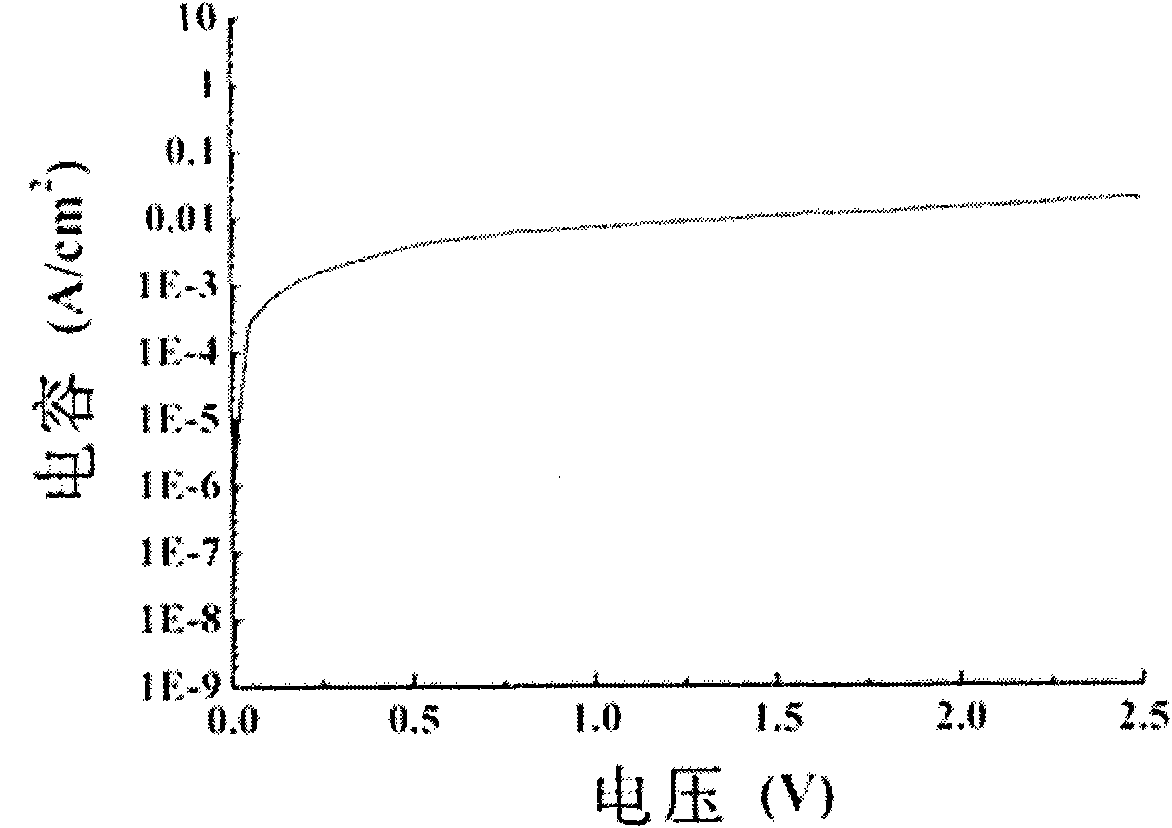

Method used

Image

Examples

Embodiment Construction

[0018] Step 1. Cleaning: After the device isolation is formed, perform the cleaning before the formation of the interface oxide layer. First, use conventional methods to clean, and then use hydrofluoric acid: isopropanol: water (weight ratio) = 0.3-0.8%: 0.01-0.08 %:1% mixed solution soak for 2-10 minutes at room temperature, rinse with deionized water, N 2 Enter the furnace immediately after spinning dry;

[0019] Step 2. Formation of interface layer SiOx: at 600-800℃, in N 2 Moderate rapid thermal annealing (RTA) 20-120 seconds; 5-8 的oxide layer;

[0020] Step 3. Formation of high dielectric constant (K) gate dielectric film: using PVD method, using magnetron reactive sputtering process in N 2 / Ar atmosphere alternately sputtering Hf-La target and Hf target deposition to form HfLaON, the working pressure of sputtering is 5×10 -3 Torr, the sputtering power is 100-500W, and the thickness of the deposited HfLaON high-k gate dielectric film is 10-60 angstroms;

[0021] Step 4. Ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com